Cast-in-place column top closed horn mouth device and construction method thereof

A construction method and bell mouth technology, which are applied in the fields of formwork/template/work frame, on-site preparation of building components, processing of building materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

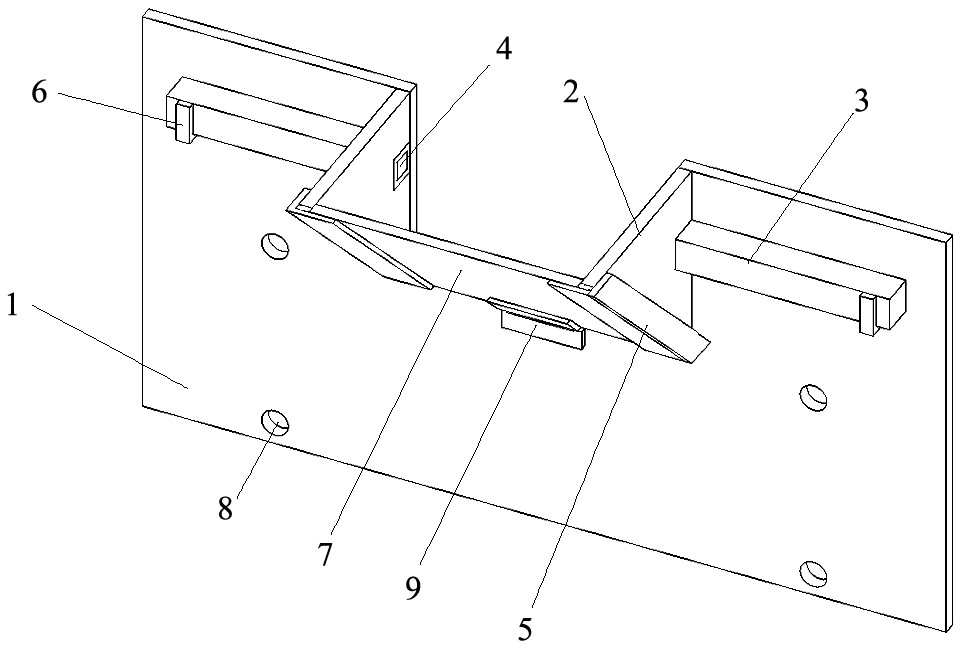

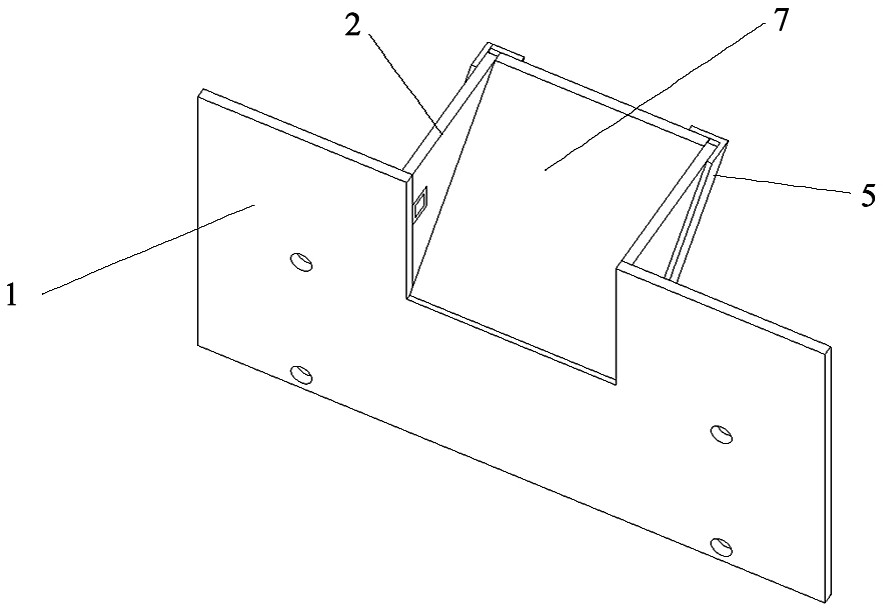

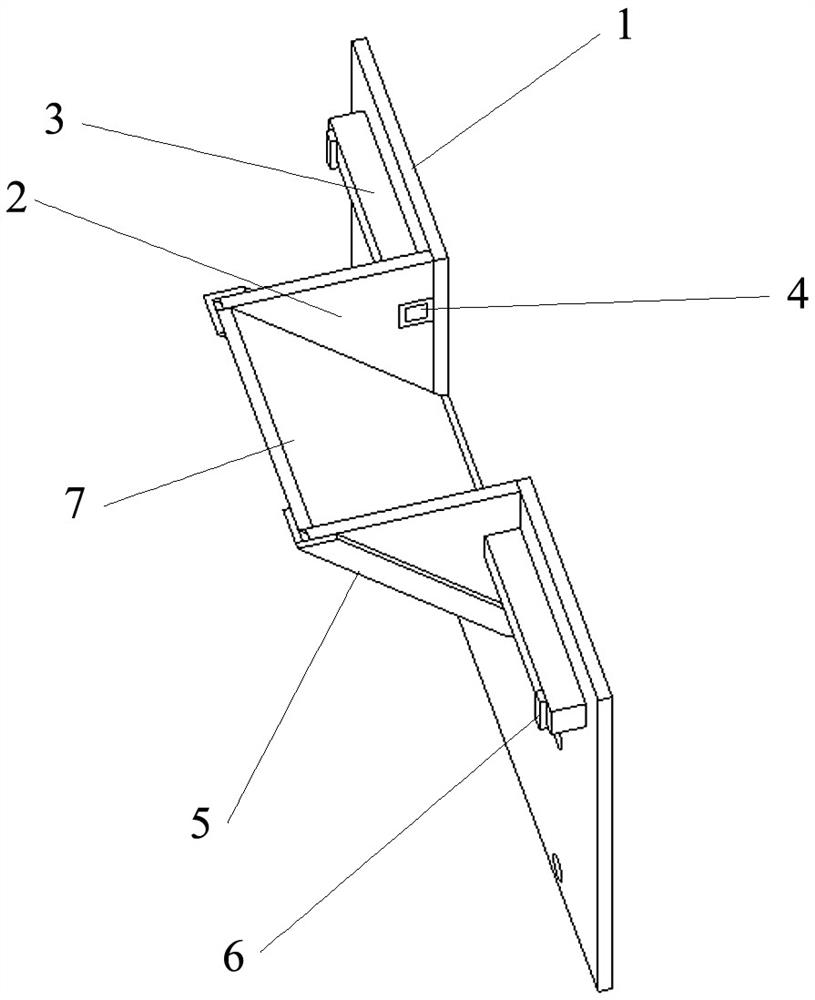

[0036] Such as Figure 1 to Figure 6 Shown are three-dimensional schematic diagrams of the bell mouth device in the open and closed state, respectively. The closed bell mouth device at the top of the cast-in-place column includes a concave plate 1, side plates 2 connected to the outer surface of the concave plate 1 and located on both sides of the notch, connected to the outer side of each side plate 2 and connected to the concave The diagonal brace 5 on the plate 1, the movable plate 7 connected between the two diagonal braces 5 and the bottom of the movable plate 7 is movably connected with the concave plate 1, and the fixed part 3 inserted between the two side plates 2 and the connection The docking piece 4 between the fixing pieces 3; wherein, the outer end of the fixing piece 3 is also connected with a bracket 6; the diagonal brace 5 is a right-angled piece, and one side of the angled piece is connected to the outer surface of the hypotenuse of the side plate 2, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com