Capacitor plastic package device for new energy automobile

A technology for new energy vehicles and capacitors, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of inconvenient collection, increased labor intensity, easy burns, etc., and achieve the effect of increasing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

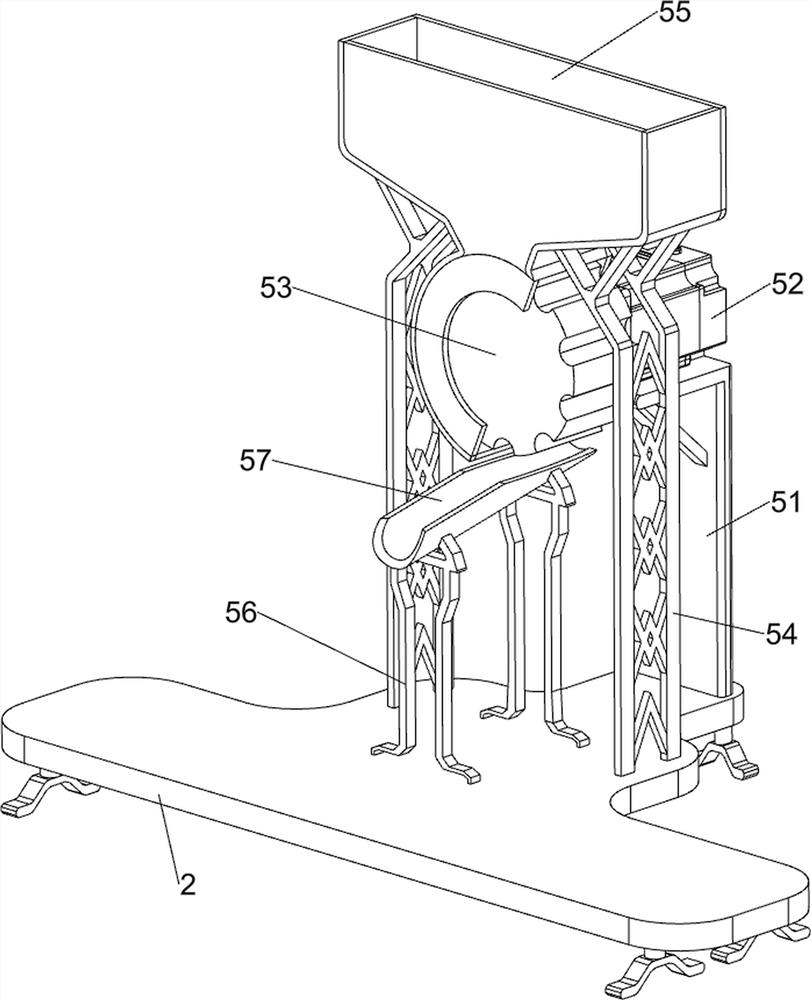

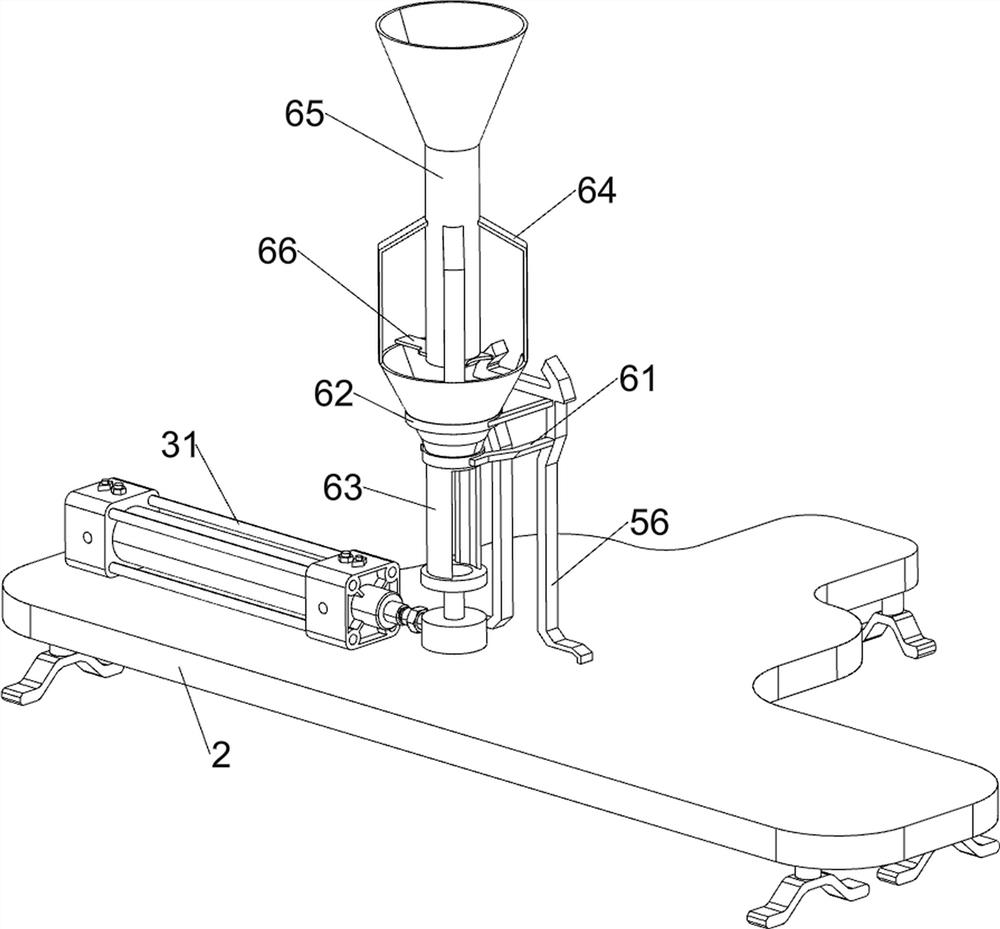

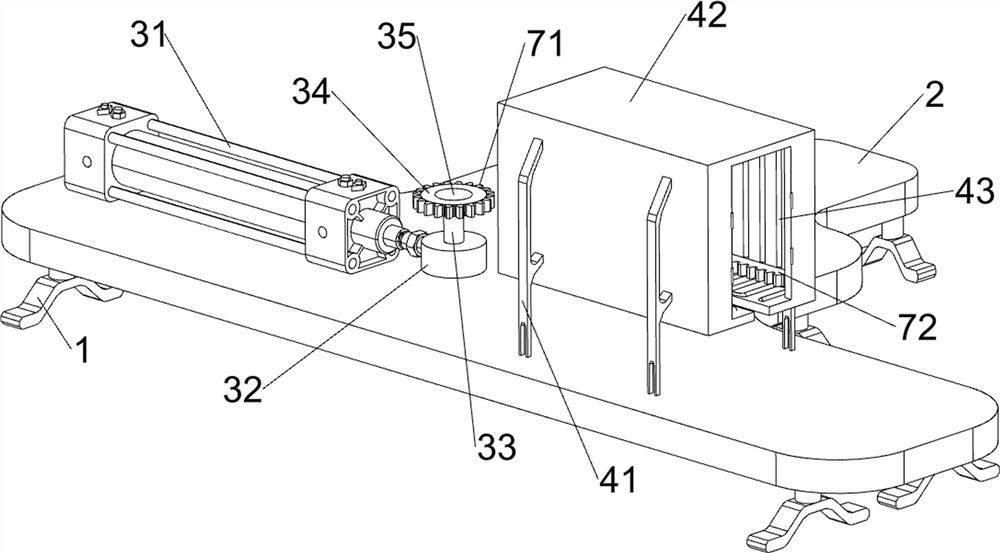

[0021] A capacitor plastic packaging device for new energy vehicles, such as Figure 1-5 As shown, it includes outrigger 1, bottom plate 2, push assembly 3 and heating assembly 4, four outriggers 1 are provided at the bottom of bottom plate 2, push assembly 3 is provided on the top left side of bottom plate 2, and heating assembly is provided on the top right side of bottom plate 2. Component 4.

[0022] When people need to plastic pack capacitors, they can use this device. First, place the capacitor on the push component 3, fix the capacitor on the push component 3, then put the thermoplastic film on the capacitor, and then start the push component 3 and the heating component 4, push the component 3 to drive the capacitor to move to the right, when the capacitor moves into the heating component 4, the heating component 4 plastic wraps the capacitor, after the plastic wrapping is completed, close the heating component 4, take out the capacitor, and then close Push component 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com