USB socket and manufacturing method thereof

A technology of plug and contact parts, which is applied to contact parts, fixed/insulating contact members, protective grounding/shielding devices of connecting parts, etc., which can solve complex processes, damage to the socket end, and the inability of the tongue to be inserted into the cavity of the plug. and other problems to achieve the effect of ensuring wear resistance and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

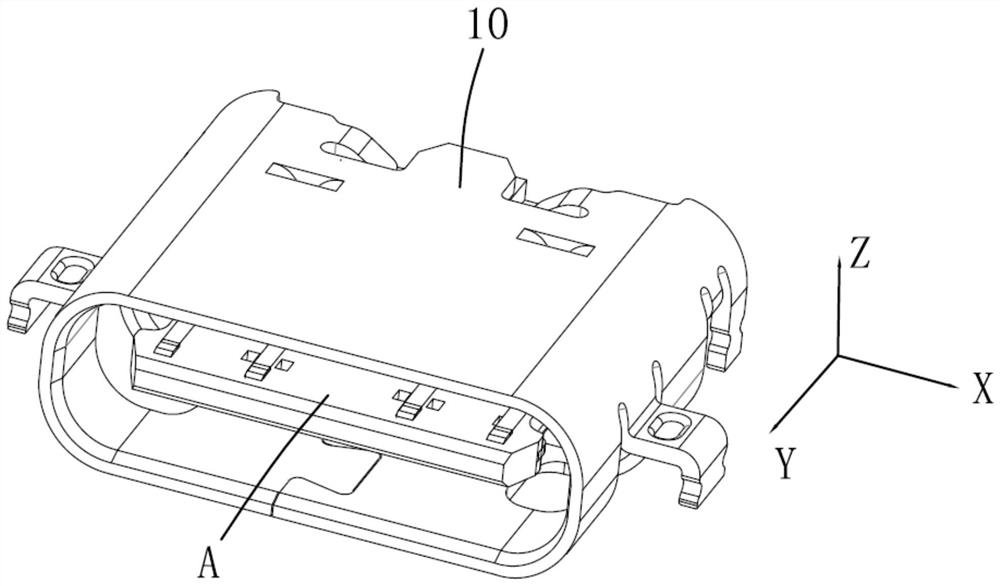

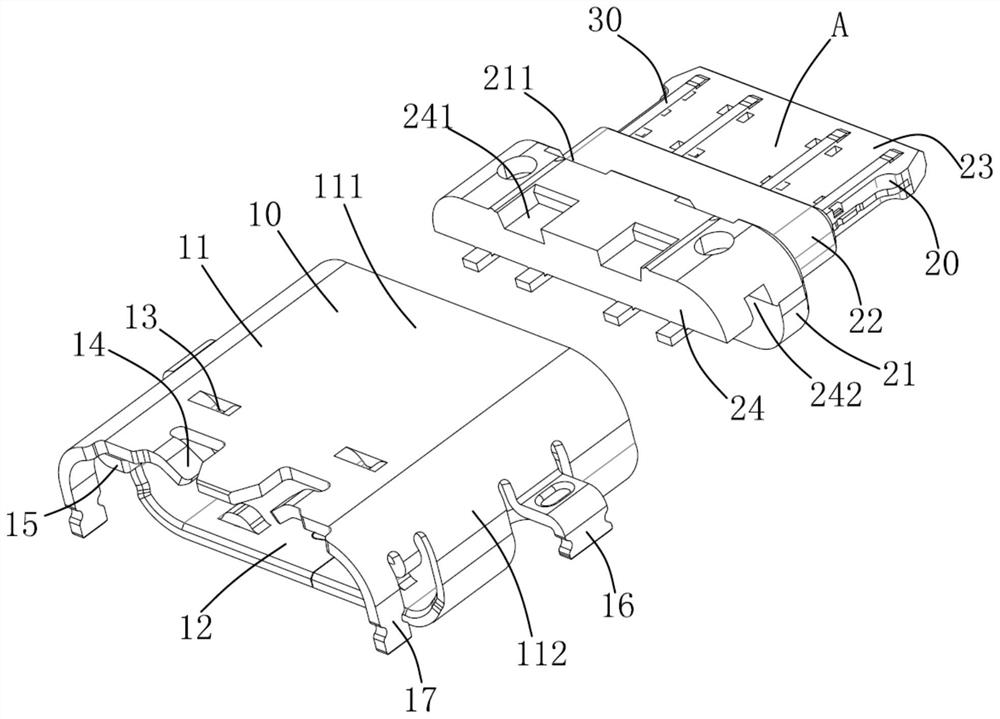

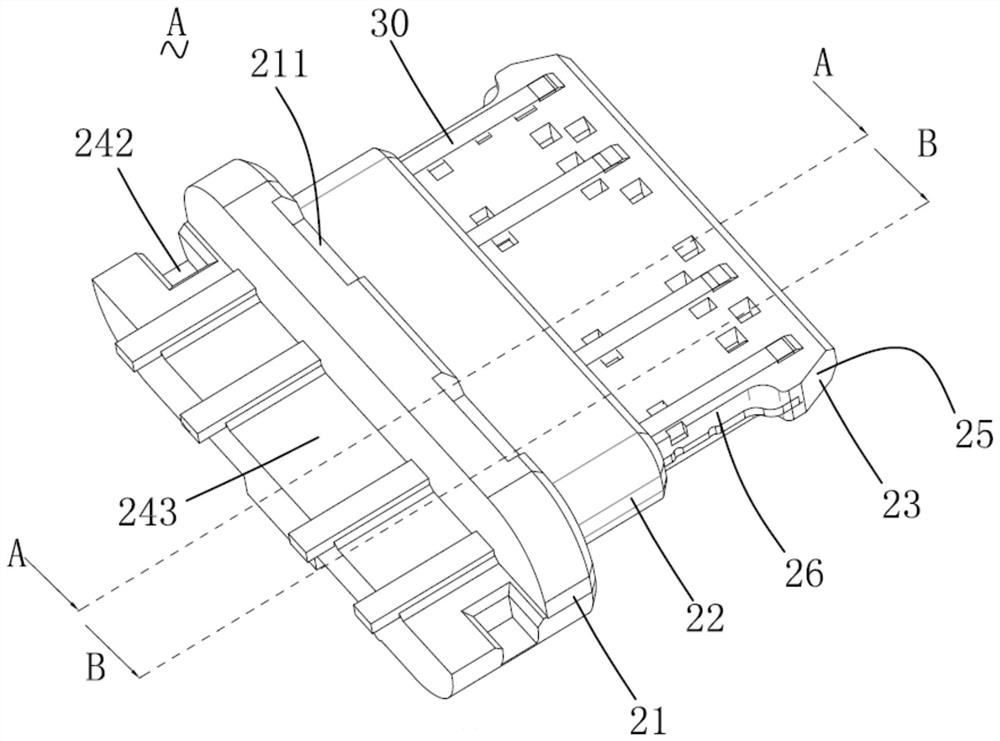

[0036] This application starts with figure 1 The X direction shown is the left-right direction (lateral direction), the Y direction is the front-rear direction (longitudinal direction), and the Z direction is the vertical direction.

[0037] see figure 1 , figure 2 As shown, the USB socket of the present application is a Type C USB socket, which supports forward and reverse plugging and unplugging. The USB socket of the present application includes a connector A and a metal casing 10 sleeved outside the connector A.

[0038] The metal shell 10 includes a cylindrical body 11 , a cavity 12 surrounded by the cylindrical body 11 , and first and second welding legs 16 and 17 punched from the cylindrical body 11 .

[0039] The cylindrical body 11 includes vertical cylindrical walls 111 on upper and lower sides and a lateral cylindrical wall 112 connecting the vertical cylindrical walls 111 in the lateral direction. The rear end of the vertical cylinder wall 111 is punched and f...

Embodiment 2

[0050] please continue Figure 9 As shown, it is a cross-sectional view of the ground terminal 31 according to the second embodiment of the present application. Compared with the first embodiment, the thinned portion 314 ′ of the ground terminal 31 of this embodiment is bent toward the side of the metal reinforcement 33 . The second plate body portion 332 is provided with a buckle hole 4 on one lateral side, and the thin portion 314 ′ of the ground terminal 31 passes through the buckle hole 4 and then abuts against the second plate body portion 332 on the leading edge 5 surface. The buckle hole 4 can be opened from the lateral inner side or the outer side, and the ground terminal 31 is inserted from the lateral opening direction of the buckle hole 4 . This design can enhance the firmness between the metal reinforcing member 33 and the ground terminal 31 and improve the contact performance.

[0051] The manufacturing method of the USB socket of the present application compris...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap