Blade winding cleaning device, lawn mower and implementation method

A technology of cleaning device and knife device, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of blade winding, reduce parking cleaning or knife replacement, and achieve the effect of protecting blades, preventing collisions, and liberating productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

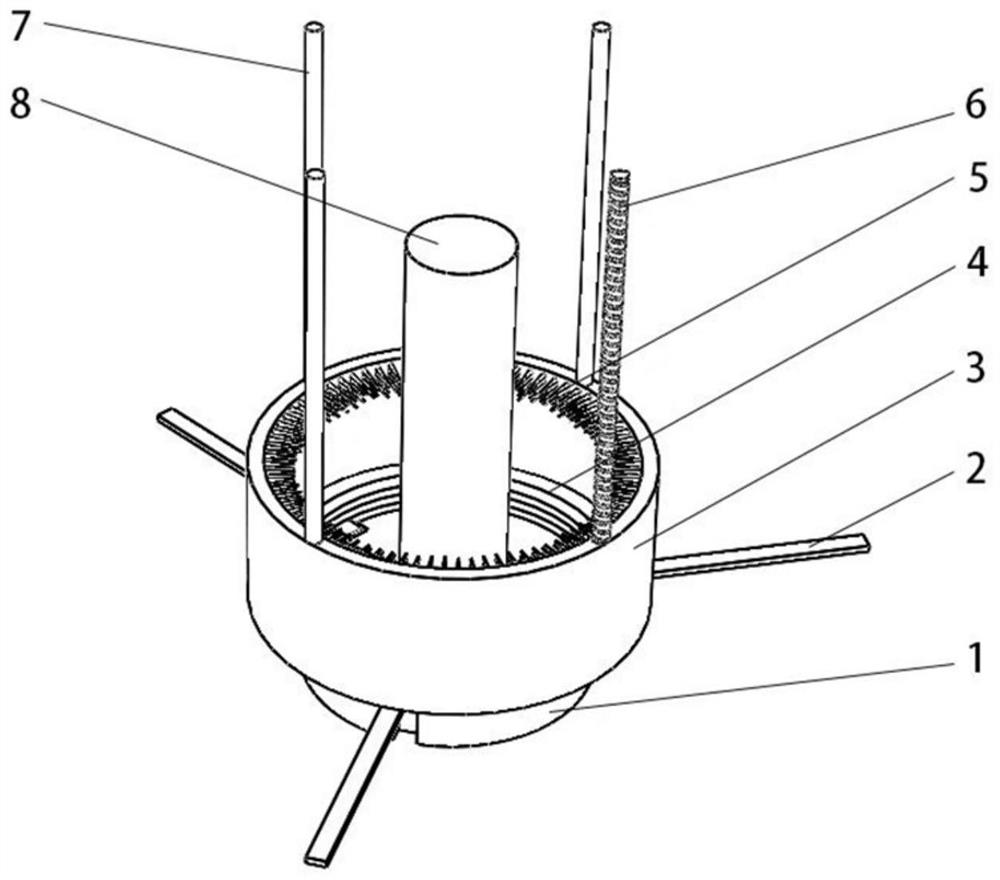

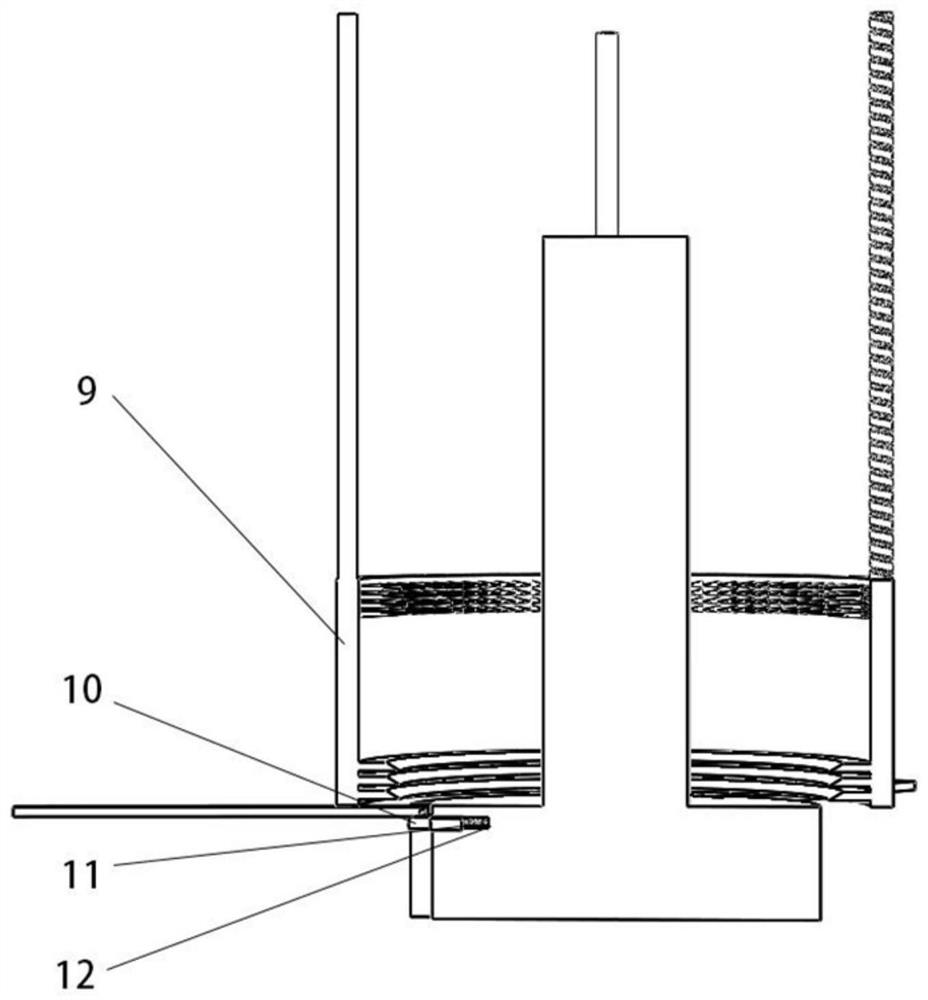

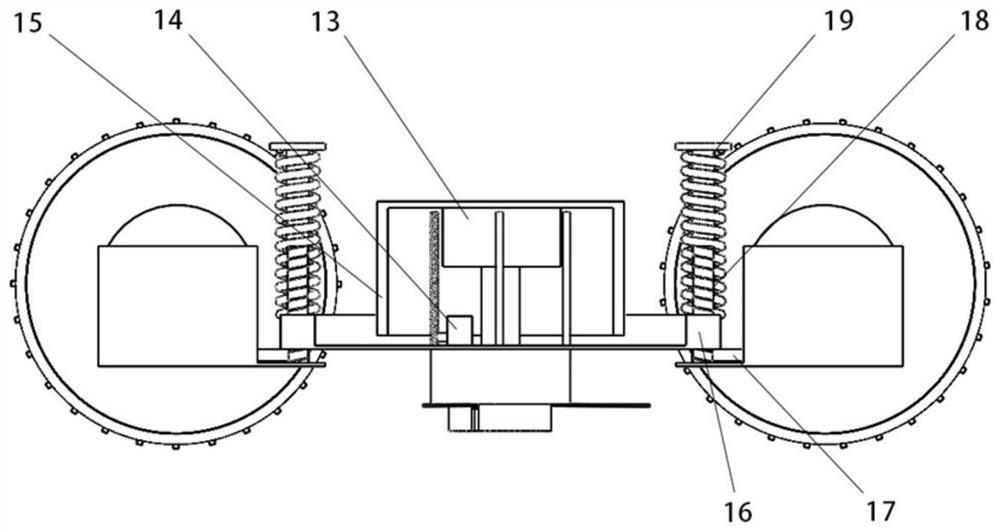

[0032] Such as figure 1 as shown in Figure 1-Figure 2 As shown, a blade winding cleaning device provided in this embodiment is used on a lawn mower, including a knife rest device, a knife pressing device, a screw drive mechanism and a chassis lifting mechanism; the knife rest device includes a knife rest 1 , mowing knife 2, slide block 10, power transmission shaft 8, return spring 11 and spring hook seat 12. The mowing knife 2 is installed on the knife rest 1, and the mowing knife 2 is supported by the slider 10 in the initial position; the knife rest 1 is fixedly connected with the transmission shaft 8, and is used to drive the mowing knife 2 to mow the grass; Described power transmission shaft 8 is connected with motor 13, is used for the power transmission of motor; Described slide block 10 is positioned at knife rest 1 inside, is used for supporting mowing knife 2 in initial position, and when pressing knife device descends, slide block 10 It can move inwards to the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com