Humidifying nasal oxygen cannula with oxygen filtering function

A nasal oxygen tube, oxygen tube technology, applied in breathing masks, valves, respirators, etc., can solve problems such as easy reduction of oxygen flow rate, inconsistent speed of adjustment, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

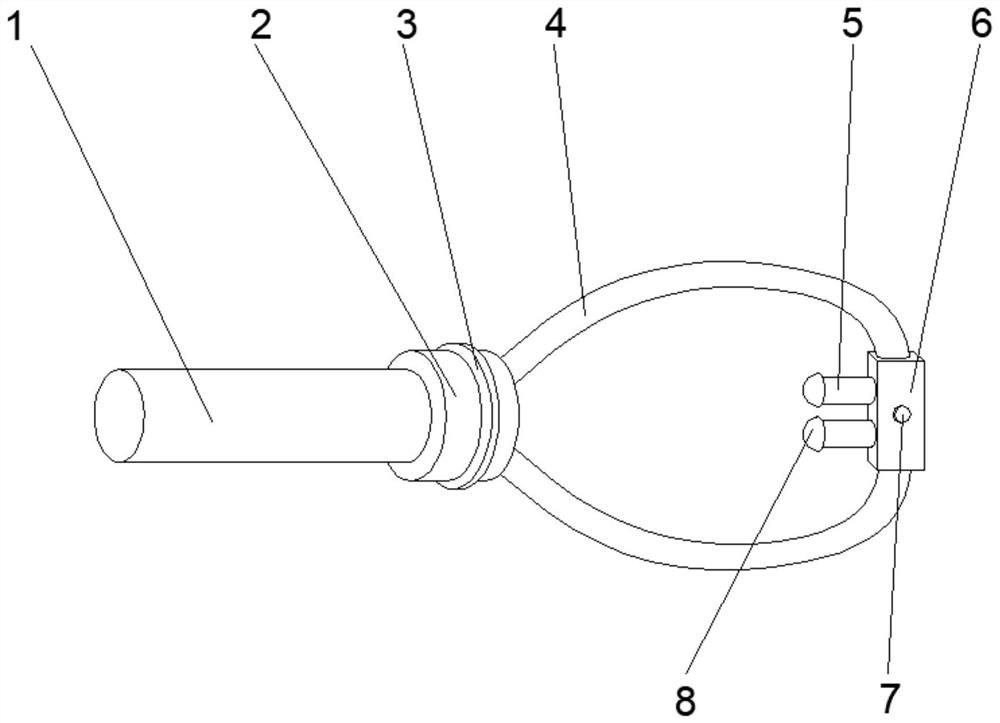

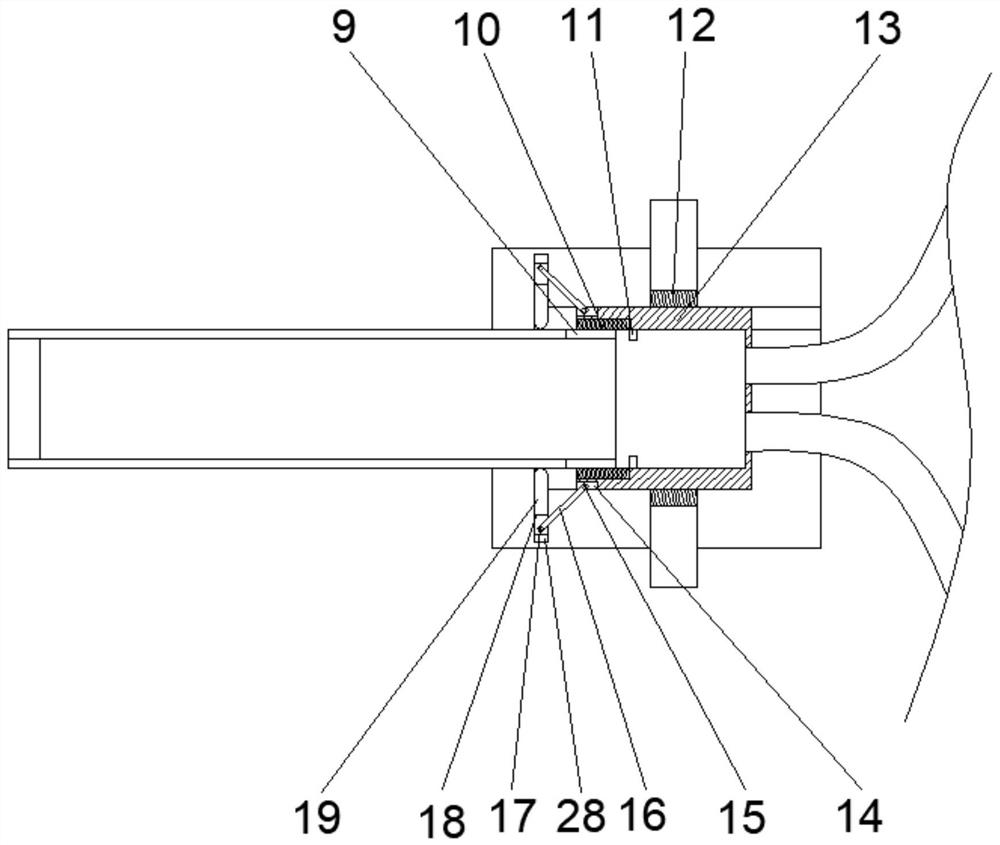

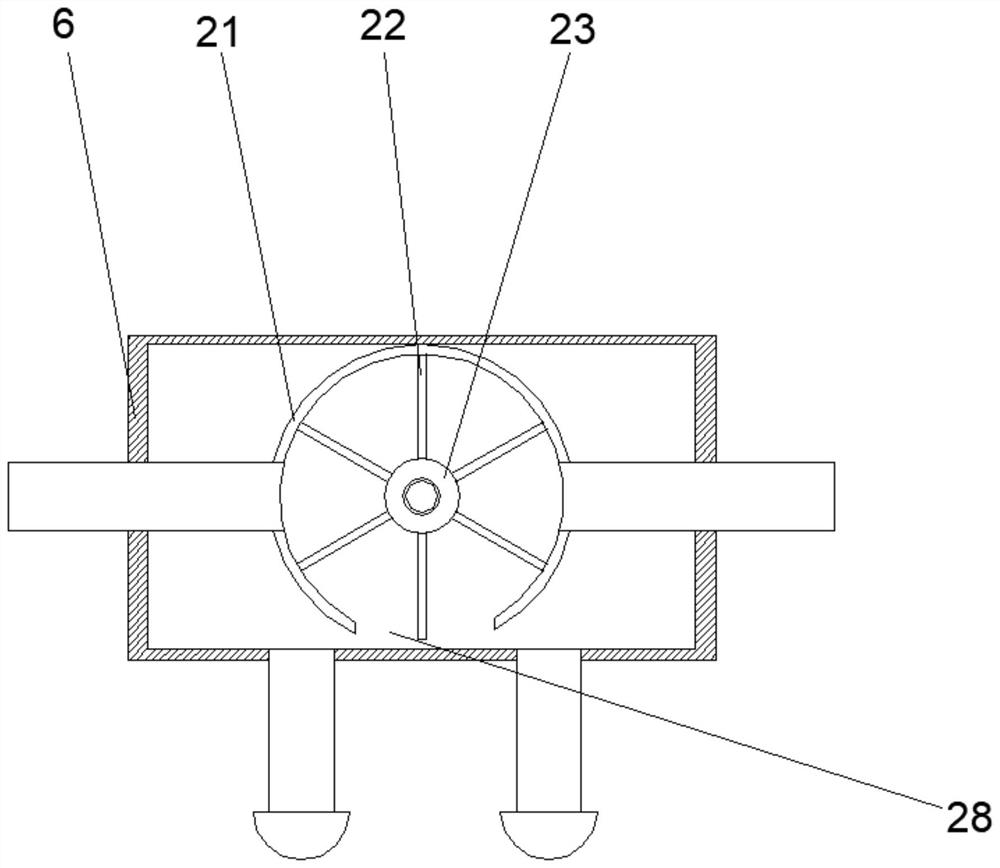

[0025] see Figure 1-4 , a humidified nasal oxygen tube with oxygen filtering function in an embodiment of the present invention, comprising an oxygen tube 1, the end of the oxygen tube 1 is provided with a first external thread 9, the end of the oxygen tube 1 is connected with a regulator 2, and the oxygen tube The end of 1 extends into the regulator 2, and the inside of the regulator 2 is provided with a connecting pipe 13, which is slidably connected to the regulator 2, and the left end of the connecting pipe 13 is connected to the end of the oxygen tube 1 by rotation, and the left end of the connecting pipe 13 is provided with a second An internal thread 10, the first internal thread 10 cooperates with the first external thread 9, the inside of the connecting pipe 13 is provided with a closed ring 11, the closed ring 11 is located on the right side of the first internal thread 10, the closed ring 11 can be connected to the oxygen tube 1 to limit the position, the right sid...

Embodiment 2

[0027] see Figure 1-4 , on the basis of Embodiment 1, the right side of the regulator 2 is provided with a rotating ring 3, the rotating ring 3 is circular, the inner ring surface of the rotating ring 3 is in rotational contact with the outer surface of the connecting pipe 13, and the inner ring of the rotating ring 3 There is a connecting pipe 13 on the surface, and the connecting pipe 13 is matched with the second external thread 27, and the outer ring surface of the rotating ring 3 protrudes outside the regulator 2, which is convenient for manual rotation adjustment.

[0028] A second chute 28 is provided at the upper and lower ends on the left side inside the regulator 2 , and a pressing plate 19 is arranged inside the second chute 28 , and the pressing plate 19 is in sliding contact with the regulator 2 .

[0029] The middle part of the pressure plate 19 is provided with a second card slot 18, and the second card slot 18 is provided with a second rotating rod 17, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com