Plasma electrochemical jet flow combined machining method and device

A plasma and composite processing technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of high risk, high hardness of semiconductor materials, strong chemical stability, etc., and achieve the effect of reducing processing costs and simple structure

Pending Publication Date: 2021-04-20

SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, chemically inert metals such as niobium and titanium and semiconductor materials such as silicon and silicon carbide have high hardness, high brittleness, and strong chemical stability, which are difficult to process by conventional methods.

[0003] Specifically, the pattern cannot be precisely controlled by wet etching, and the etchant is a dangerous strong acid or alkali such as hydrofluoric acid or potassium hydroxide; dry etching has the risk of wafer damage, and the equipment is complicated and expensive. Not suitable for mass production; EDM a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

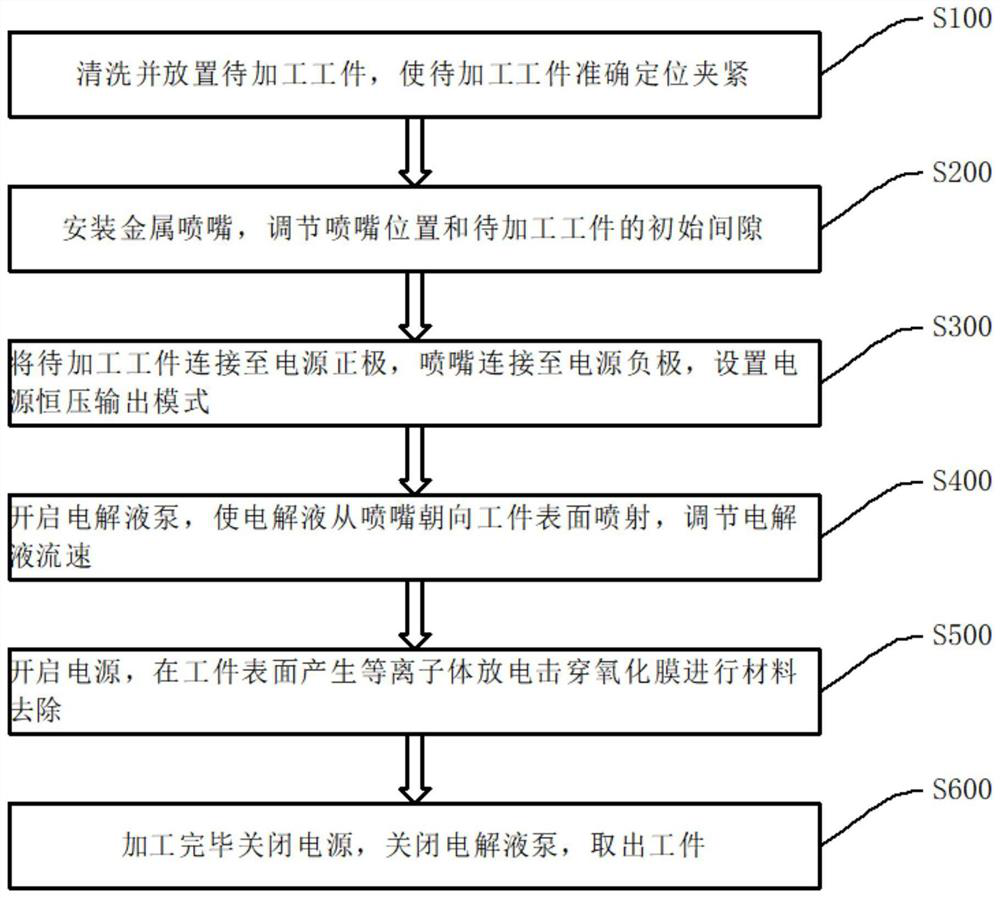

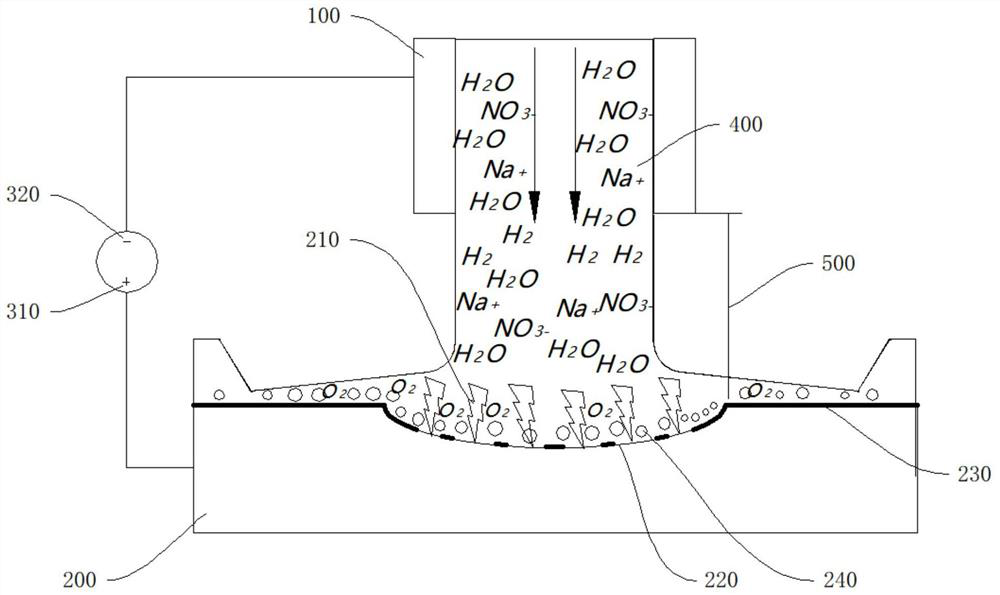

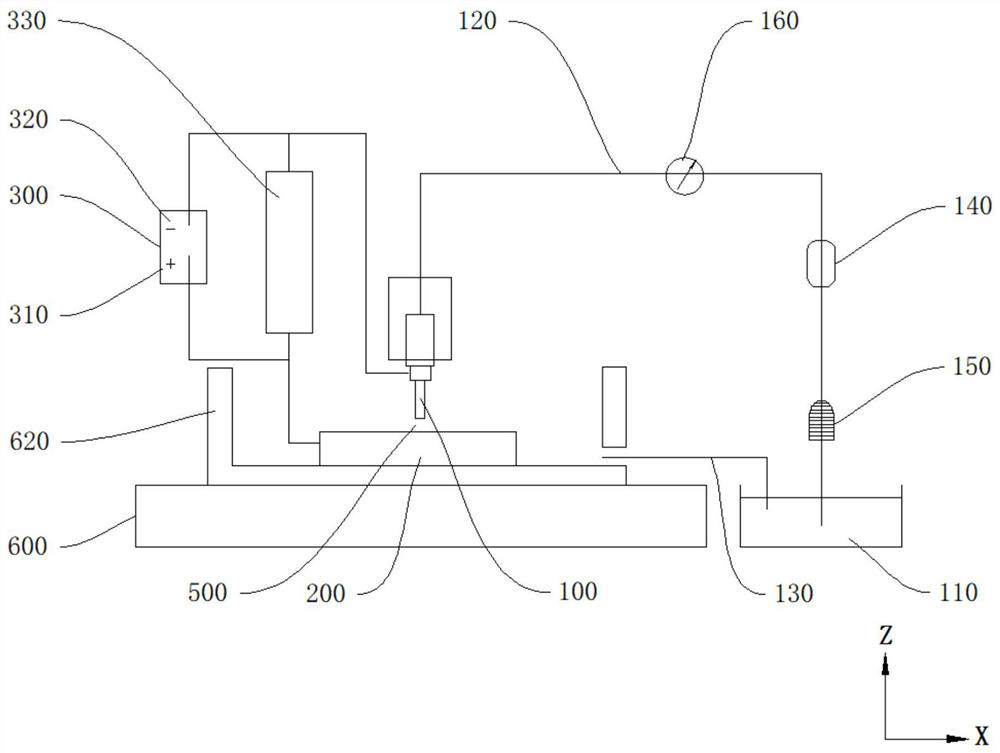

The invention relates to the technical field of combined machining, and discloses a plasma electrochemical jet flow combined machining method and device. Electrolyte forms jet flow through a jetting device to be jetted on a workpiece, and plasmas are generated on the surface of the workpiece by applying proper voltage, so that an oxidation film generated by electrochemical jet flow on the surface of the workpiece is broken through, electrolytic plasma machining and electrochemical jet machining are combined, and machining of chemical inert materials is achieved. A workbench is arranged on a rack of the plasma electrochemical jet flow combined machining device, a clamp is arranged on the workbench, and the jetting device comprises a nozzle which faces the clamp and is used for spraying electrolyte to the workpiece. The combined machining mode of electrolytic plasma machining and electrochemical jet machining can be achieved only by clamping a to-be-machined workpiece on the clamp, connecting the nozzle to the negative electrode of a power source, connecting the workpiece to the positive electrode of the power source and spraying electrolyte to the surface of the workpiece through the nozzle, the structure is simple, and the machining cost can be effectively reduced.

Description

technical field [0001] The invention relates to the technical field of composite processing, in particular to a plasma electrochemical jet composite processing method and device. Background technique [0002] With the continuous innovation of semiconductor technology, in recent years, the third-generation semiconductor materials led by silicon carbide (SiC) have the advantages of large band gap, high breakdown electric field, and high thermal conductivity. The development potential of high-power semiconductor devices is huge. Conventional processing methods mainly include wet etching, dry etching, electric spark, laser, chemical or electrochemical processing, etc. Chemically inert metals play an important role in high-tech fields such as aerospace, energy, and medical treatment due to their high thermal stability and corrosion resistance. For example, niobium (Nb) and its alloys can be used in superconducting magnets, superalloys It can be used in rocket propulsion nozzles...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P15/00B23P23/00

Inventor 赵永华董邦彦卢家俊

Owner SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com