Metal plate intelligent polishing device

A technology of metal plate and polishing device, which is applied in the direction of grinding drive device, metal processing equipment, grinding/polishing equipment, etc., and can solve the problems of unstable hydraulic pressure of the polishing wheel and poor polishing flatness of the surface of the metal plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

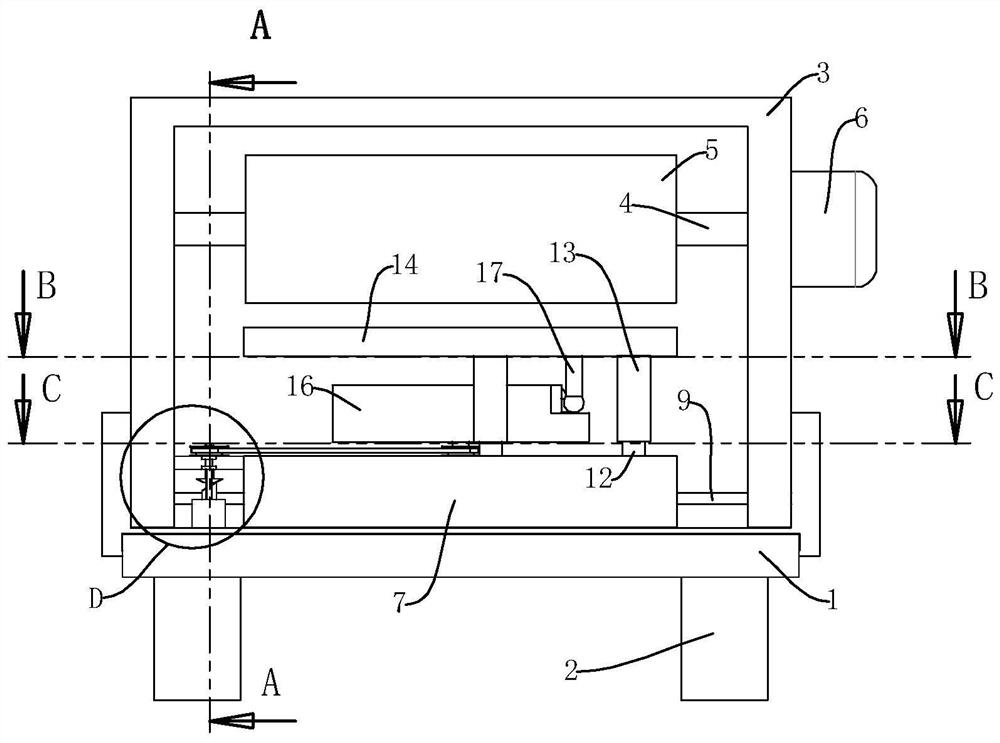

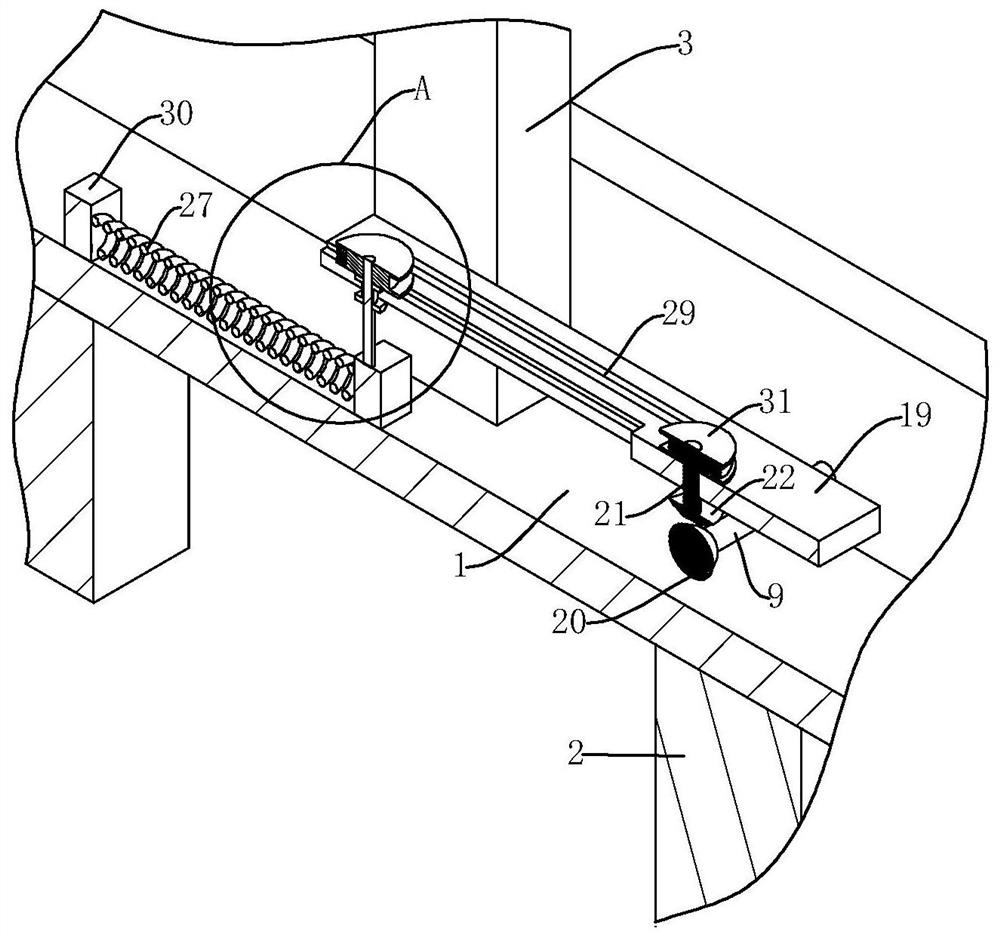

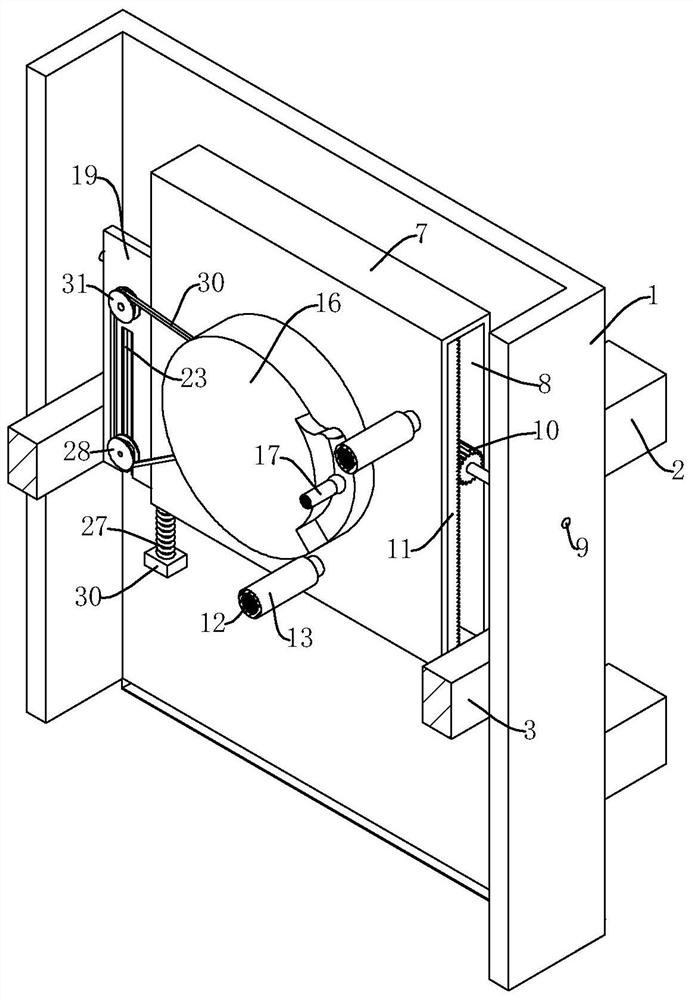

[0024] refer to Figure 1-6 , an intelligent polishing device for metal plates, comprising a base 1, four support columns 2 are evenly and fixedly installed on the bottom of the base 1, a U-shaped frame 3 is fixedly installed in the middle of the top of the base 1, and a rotating shaft 4 is installed on the inner side of the U-shaped frame 3 through bearings, Grinding roller 5 is fixedly installed on the shaft 4 in the U-shaped frame 3, and a motor 6 is fixedly installed on the outside of the U-shaped frame. A groove 8 is provided, and a rotating rod 9 is placed on one side of the base 1. The rotating rod 9 runs through the base 1 and the groove 8 and is installed on the base 1 through bearings (the two ends of the rotating rod 9 are installed on the base 1 through bearings, and the rotating rod 9 9 completely penetrates through the groove 8), a gear 10 is fixedly installed on the rotating rod 9 inside the groove 8, and a rack 11 is installed in the groove 8 through a bolt, an...

Embodiment 3

[0028] refer to Figure 1-6 , the adjustment mechanism includes a chute 23 set on the fixed plate 19, a fixed block 30 installed on the base 1, a slider 24 is slidably arranged in the chute 23, a cylinder 25 is placed on the slider 24, and the cylinder 25 runs through the slider 24 and connecting block 26 is installed by bearing, and spring 27 is installed between connecting block 26 and fixed block 30, and the third pulley 28 is installed on the column 25 at the top of slide block 24 by bearing, first pulley 18, second pulley 31 , A belt 29 is installed between the third pulley 28, clearance fit between the slide block 24 and the chute 23, and the spring 27 is carbon spring steel. By setting the clearance fit between the slider 24 and the slide groove 23 , the movement of the third pulley 28 is more stable, thereby indirectly increasing the service life of the slider 23 . By setting the spring 27 as carbon spring steel, the service life of the spring 27 is increased, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com