Cylinder type clamp

A fixture and barrel technology, which is applied in the direction of grinding workpiece supports, etc., can solve problems such as easy deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

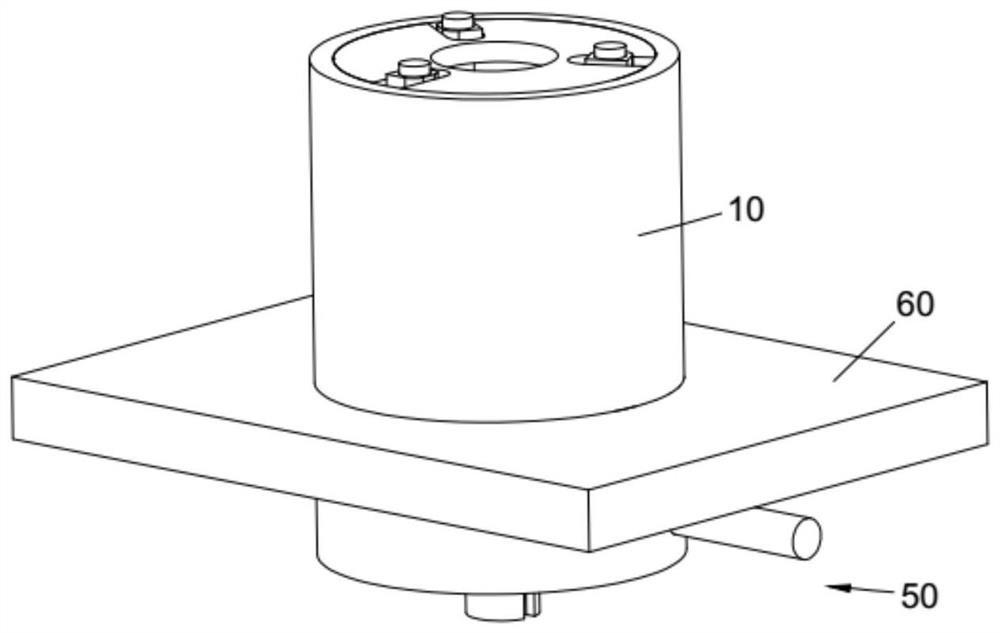

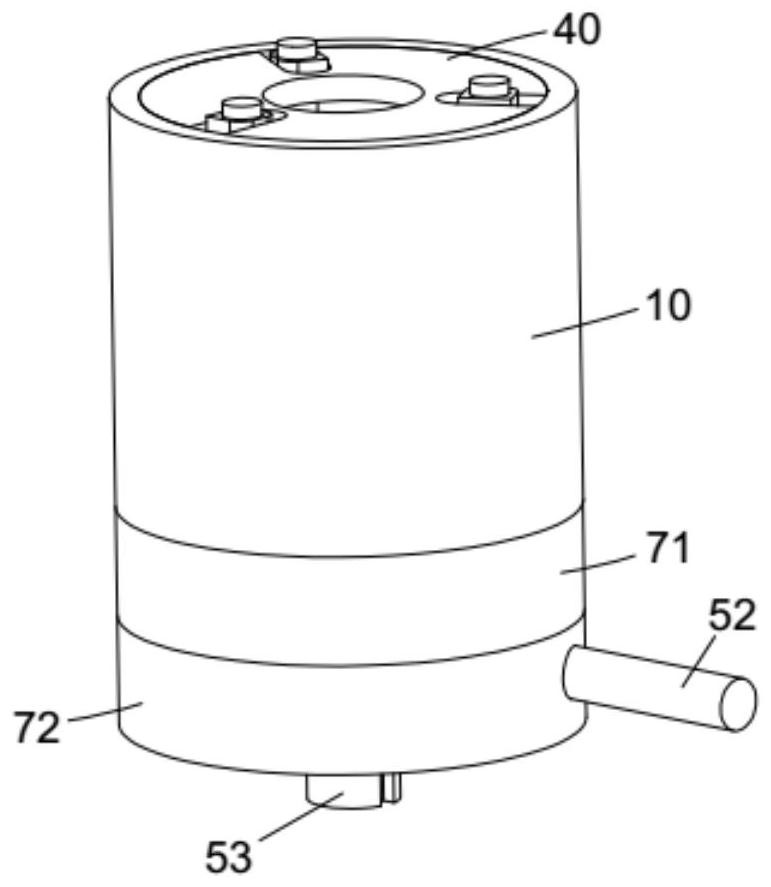

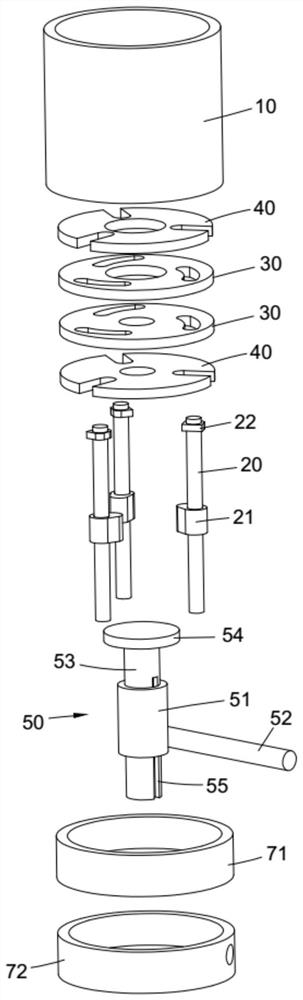

[0024] combine Figure 1 to Figure 4 , a barrel clamp, including a barrel 10, a rod 20, a track plate 30, a guide plate 40, and a rotating device 50.

[0025] The cylinder 10 is fixed on the workbench 60, the track disk is fixed in the cylinder, the guide disk is pivotally connected in the cylinder, and the guide disk is connected with the rotating device; Figure 7 As shown, the head end 32 of any arc-shaped groove is closer to the center of the track disc than the tail end 33, and the guide disc is provided with some radial guide grooves 41, such as Figure 8 As shown, a number of guide grooves and a number of arc-shaped grooves are set up and down correspondingly in a one-to-one manner, and a rod 20 is inserted in each arc-shaped groove, the rod passes through the guide groove, and a clamping block 21 is provided on the rod.

[0026] Rod parts extend into the barrel 10, manually drive the rotating device 50, the rotating device drives the guide disc 40 to rotate, the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com