Ham sausage slicing equipment

A ham sausage and slicing technology, which is applied in metal processing and other directions, can solve the problem of easy cut hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

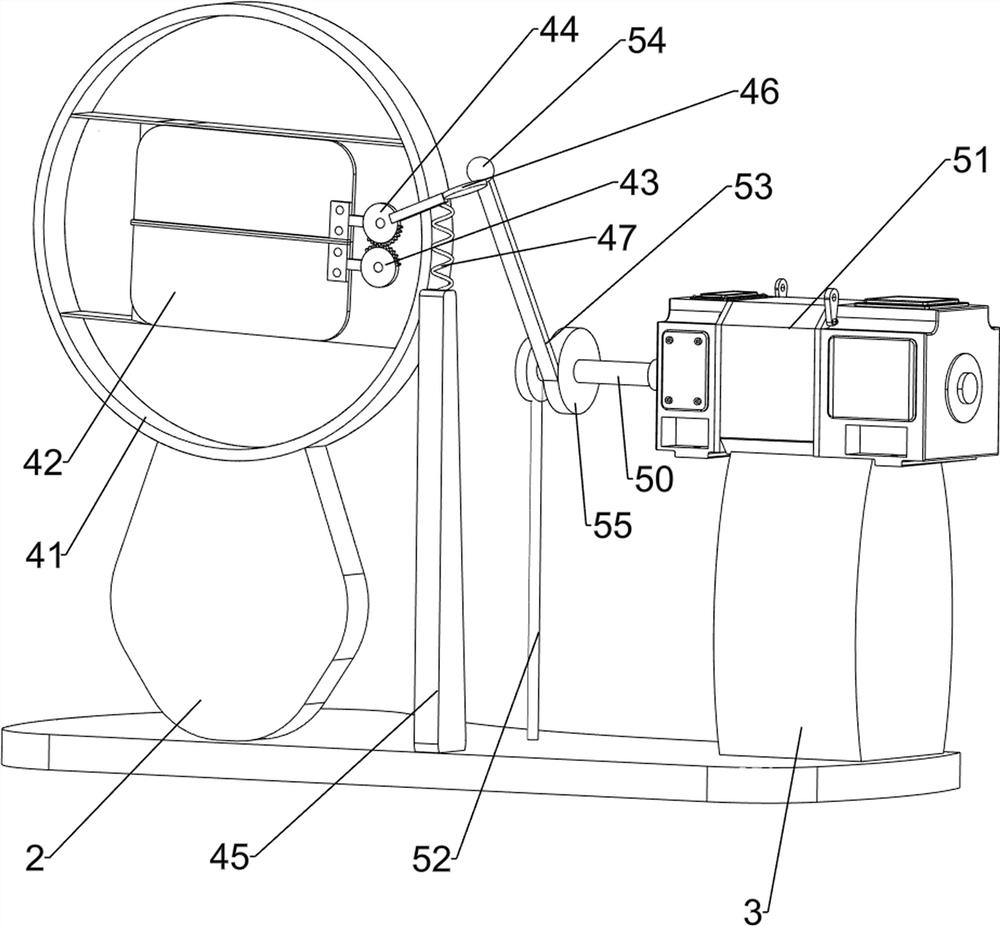

[0024] A kind of ham sausage slicing equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a mounting plate 2, a mounting block 3, a slicing mechanism 4, a driving mechanism 5, and a placement plate 6. The left side of the top of the bottom plate 1 is connected to the mounting plate 2, and the top right side of the bottom plate 1 is connected to the mounting block 3. A slicing mechanism 4 is installed on the mounting plate 2 , a placement plate 6 is connected to the slicing mechanism 4 , and a driving mechanism 5 is installed on the mounting block 3 .

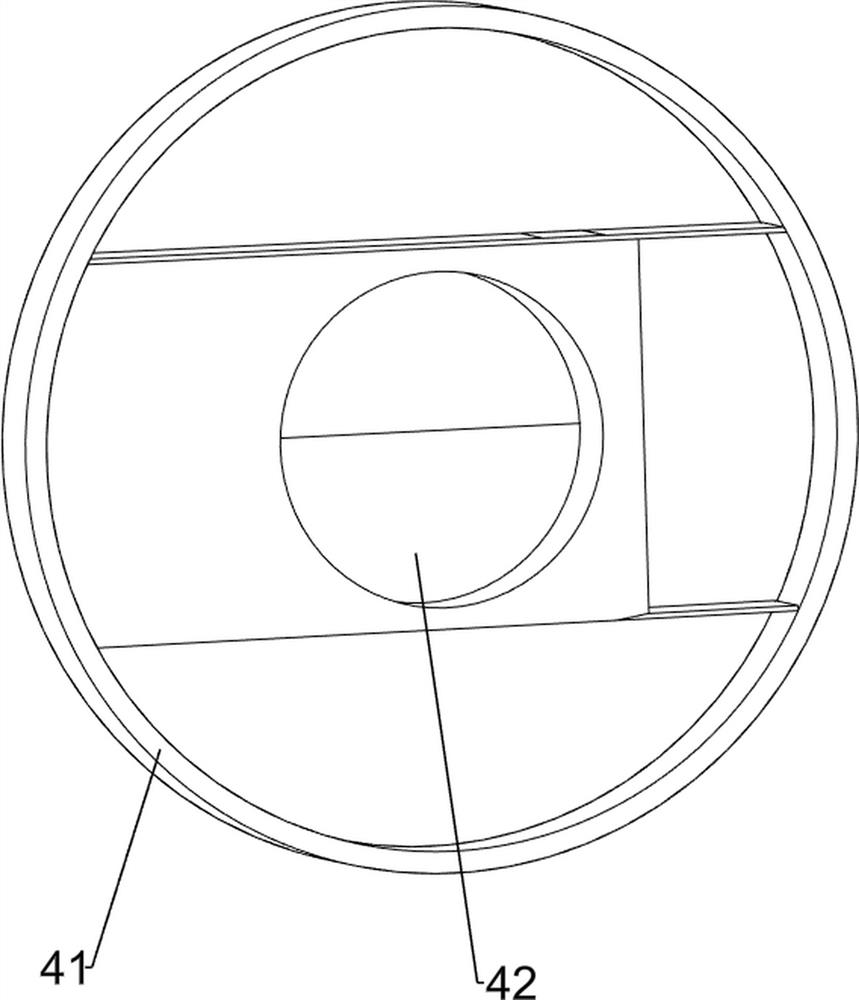

[0025] The slicing mechanism 4 includes a circular frame 41, a cutter 42, the first sector gear 43, the second sector gear 44, a support plate 45, a movable plate 46 and a first spring 47, the top of the mounting plate 2 is connected with the circular frame 41, and the plate is placed 6 is connected to the rear side of the round frame 41. The right part of the front side of the round frame 41 is rotatably conne...

Embodiment 2

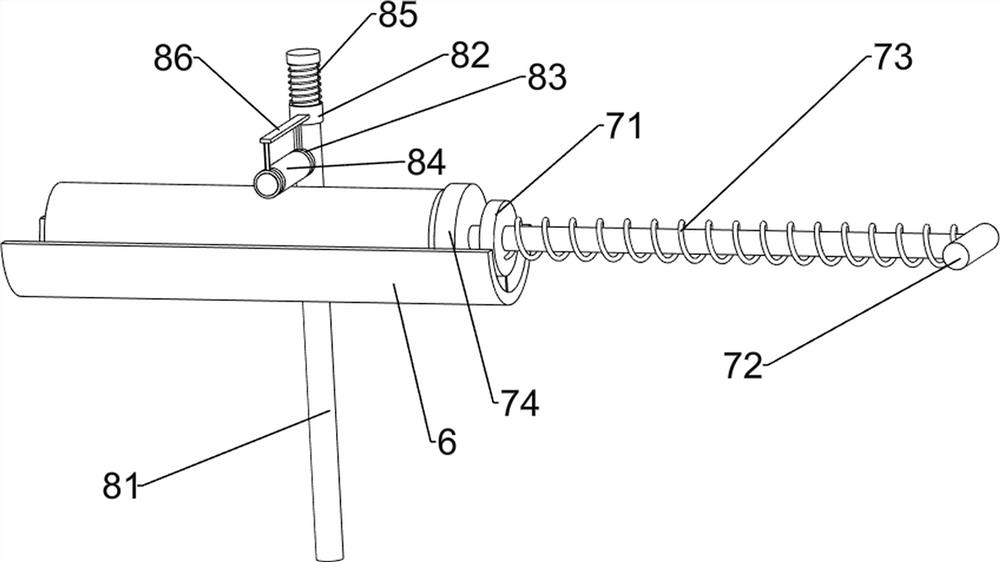

[0029] On the basis of Example 1, such as figure 1 and Figure 4 As shown, push mechanism 7 is also included, and push mechanism 7 includes guide frame 71, push rod 72, second spring 73 and push block 74, and the rear portion in placing plate 6 is connected with guide frame 71, slides in guide frame 71 A push rod 72 is connected to the push rod 72, a second spring 73 is connected between the push rod 72 and the guide frame 71, and a push block 74 is connected to the front end of the push rod 72.

[0030] When the ham sausage 9 is to be moved forward, the push rod 72 can be pushed forward so that the push block 74 moves forward, the second spring 73 is compressed thereupon, and the forward movement of the push block 74 can push the ham sausage 9 to move forward. This can facilitate the movement of the ham sausage 9. When the ham sausage 9 is sliced, release the push rod 72, and under the action of the second spring 73, the push rod 72 and the push block 74 can be moved backwar...

Embodiment 3

[0032] On the basis of Example 2, such as figure 1 and Figure 4 As shown, it also includes a limit mechanism 8, the limit mechanism 8 includes a pole 81, a guide sleeve 82, a sleeve rod 83, a rotating roller 84, a third spring 85 and a connecting plate 86, and the bottom left rear side of the bottom plate 1 is connected with a support Rod 81, a guide sleeve 82 is slidably connected to the pole 81, a third spring 85 is connected between the guide sleeve 82 and the pole 81, a connecting plate 86 is connected to the outer wall of the guide sleeve 82, and the bottom of the connecting plate 86 is symmetrically connected with Two sleeve rods 83 are rotatably connected with a rotating roller 84 between the two sleeve rods 83 .

[0033] When the ham sausage 9 is to be placed on the placement plate 6, the connecting plate 86 is moved upwards, and the upward movement of the connecting plate 86 drives the parts on it to move upwards, the third spring 85 is compressed thereupon, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com