Slicing device for carambola pulp can production

A technology of slicing device and pulp, applied in metal processing and other directions, can solve the problems of large labor consumption and splashing of juice, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

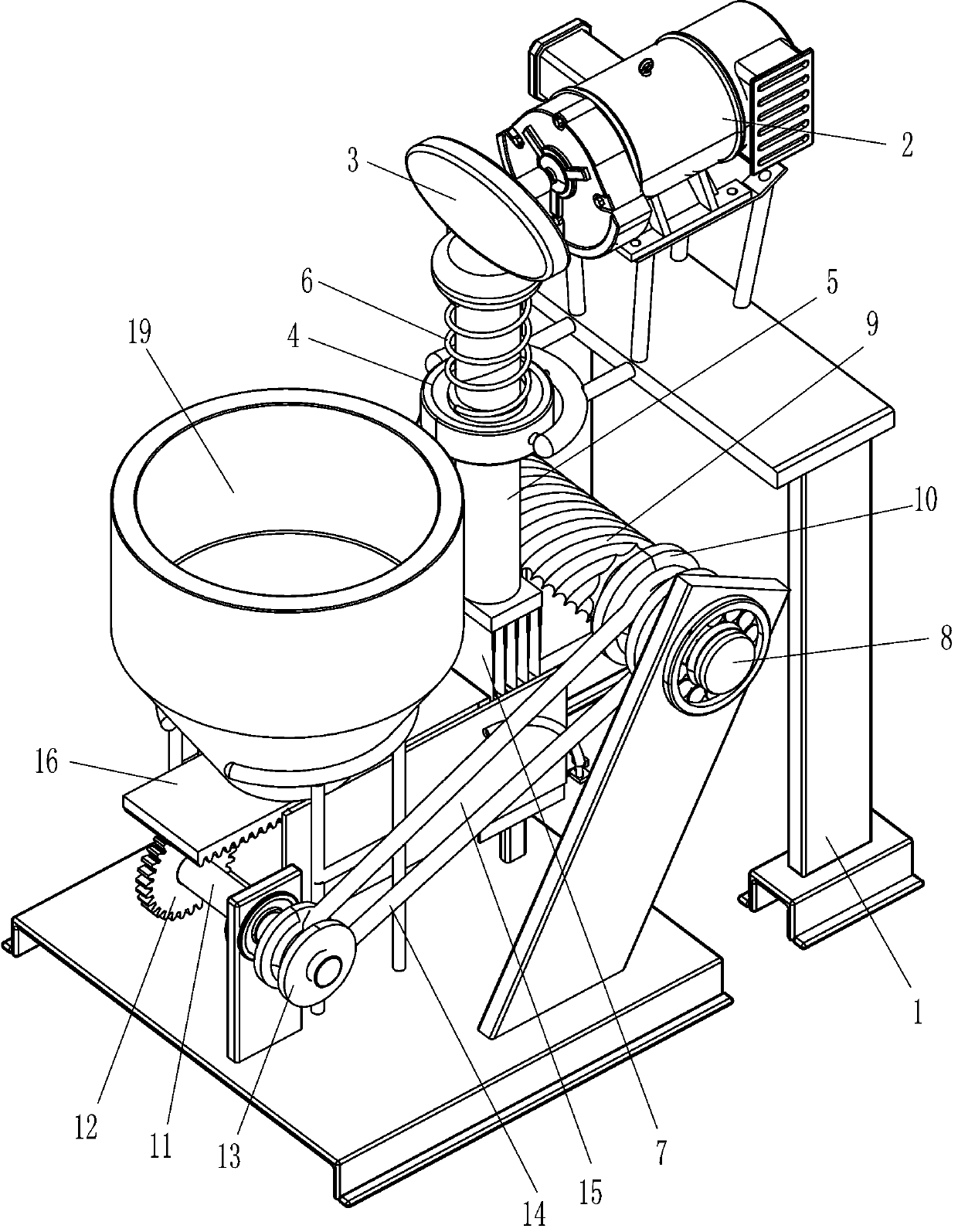

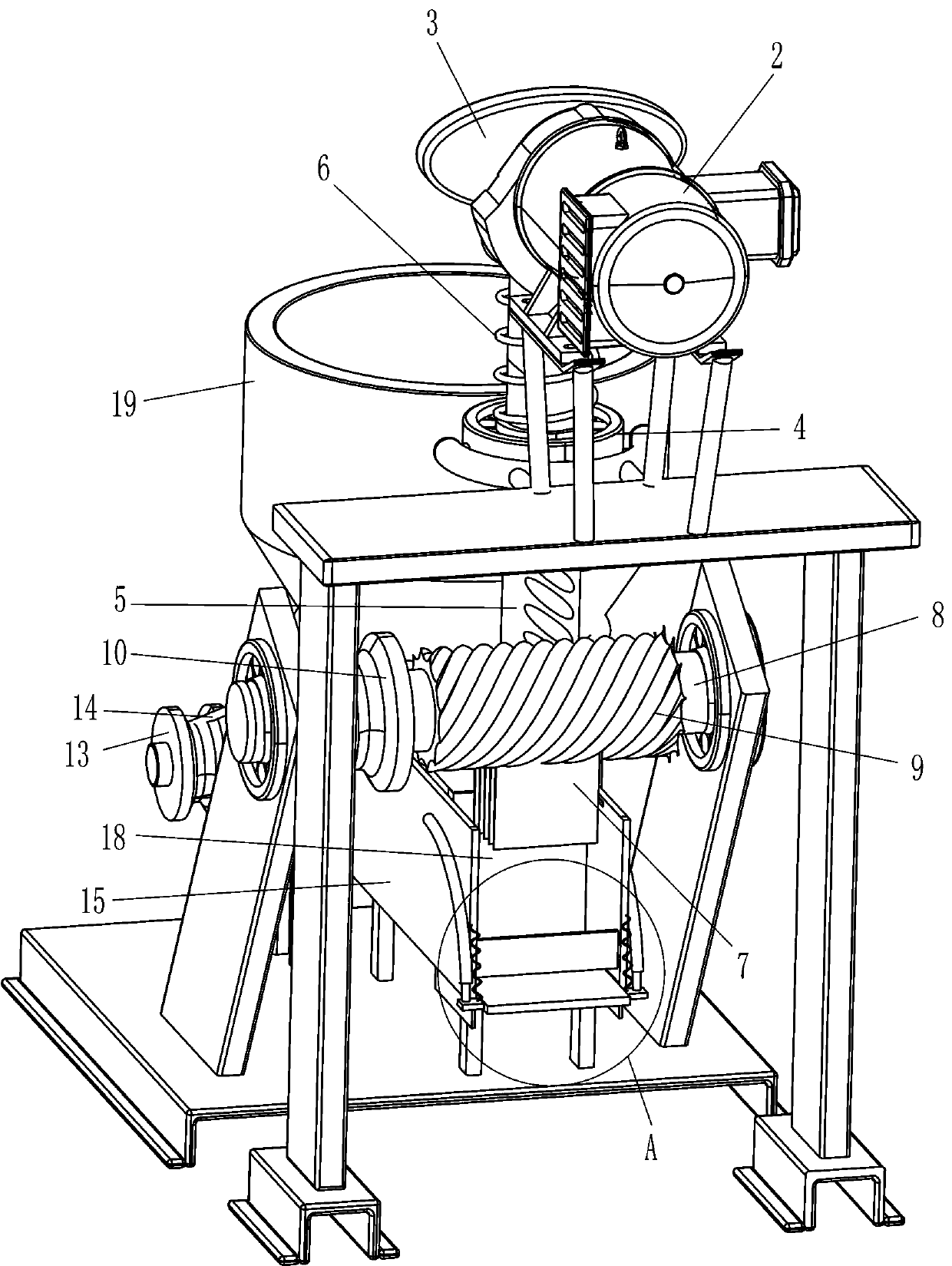

[0021] A slicing device for the production of canned carambola pulp, such as figure 1 and 2 As shown, it includes a frame 1, a slicing assembly and a feeding and pushing assembly. The right side of the top of the frame 1 is provided with a slicing assembly powered by a motor for slicing. The feeding and pushing components of the material.

[0022] Such as figure 1 and 2 As shown, the slicing assembly includes a geared motor 2, a cam 3, a guide sleeve 4, a helical rack 5, a first spring 6 and a cutter 7, the right side of the top of the frame 1 is connected with a geared motor 2 by bolts, and the geared motor 2 A cam 3 is provided on the output shaft, a guide sleeve 4 is welded on the right side of the top of the frame 1, and a helical rack 5 is slid inside the guide sleeve 4, and a first spring is connected between the top of the guide sleeve 4 and the upper part of the helical rack 5 6. The bottom end of the helical rack 5 is connected with a cutter 7 by bolts.

[0023] ...

Embodiment 2

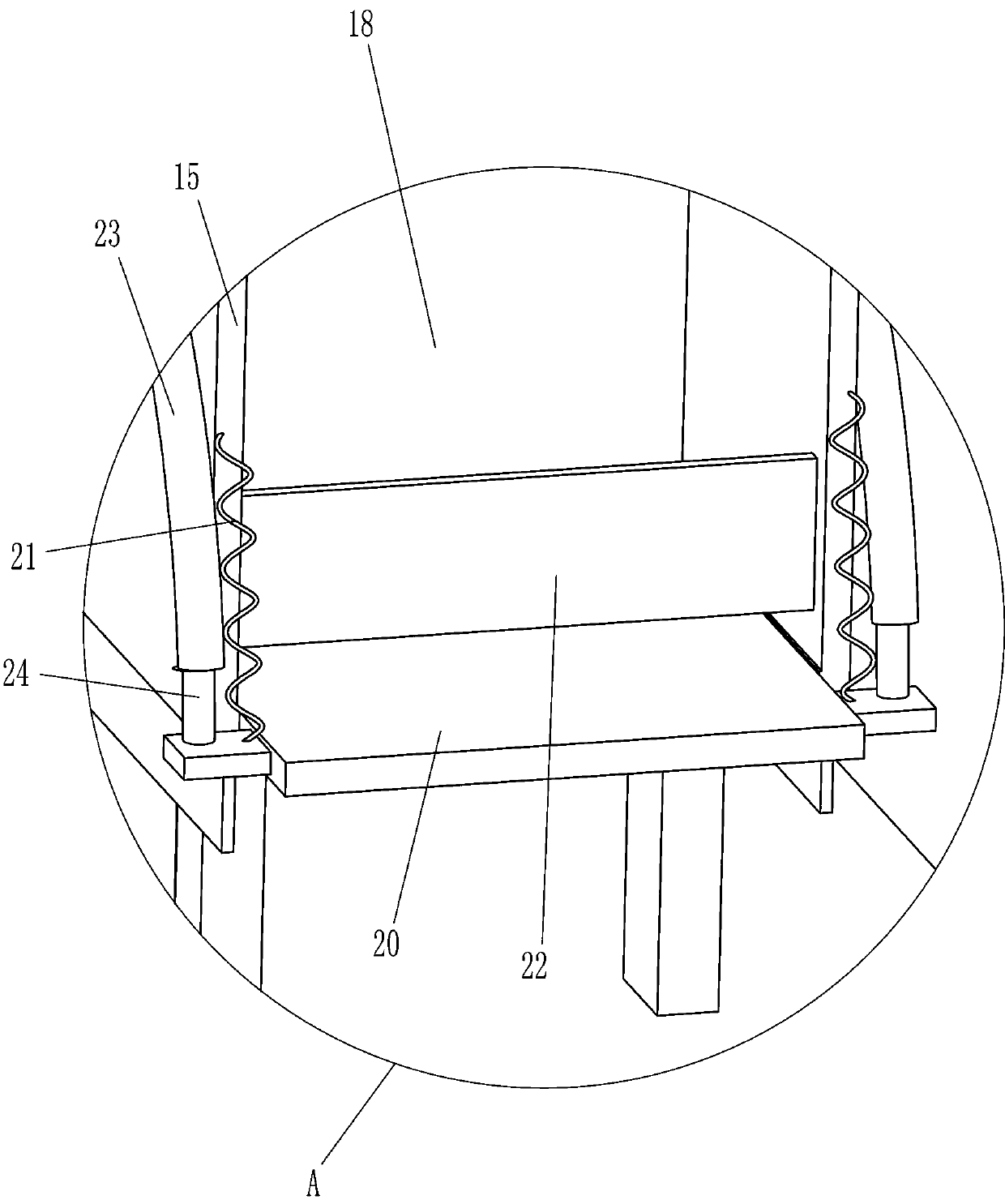

[0028] On the basis of Example 1, such as figure 2 and 3 As shown, it also includes a blanking plate 20, a second spring 21 and a baffle plate 22, and the right side of the bottom of the concave frame 15 is rotated to be provided with a blanking plate 20, and the blanking plate 20 is symmetrically connected with the concave frame 15. Second spring 21 is arranged, and baffle plate 22 is arranged on the lower right part in the concave frame 15, and baffle plate 22 cooperates with blanking plate 20.

[0029] Such as figure 2 and 3 Shown, also comprise hollow pipe 23 and piston rod 24, concave frame 15 right part is provided with hollow pipe 23 symmetrically front and rear, all sliding type is provided with piston rod 24 in the hollow pipe 23, and piston rod 24 bottoms and blanking plate 20 connections.

[0030] The specific operation method of the above-mentioned embodiment: after the carambola is sliced, the cutter 7 will continue to move down a short distance, push the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com