Continuous cycle industrial production method of 5-tert-butyl-5-hydroxy-1,3-diphenyl-2,4-imidazolidinone

A technology of imidazolidinediones and production methods, applied in the direction of organic chemistry, etc., can solve the problems of inability to realize industrialization, continuous production, inability to realize continuous production, cumbersome production procedures, etc., achieve conventional production equipment, reduce The production of three wastes and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

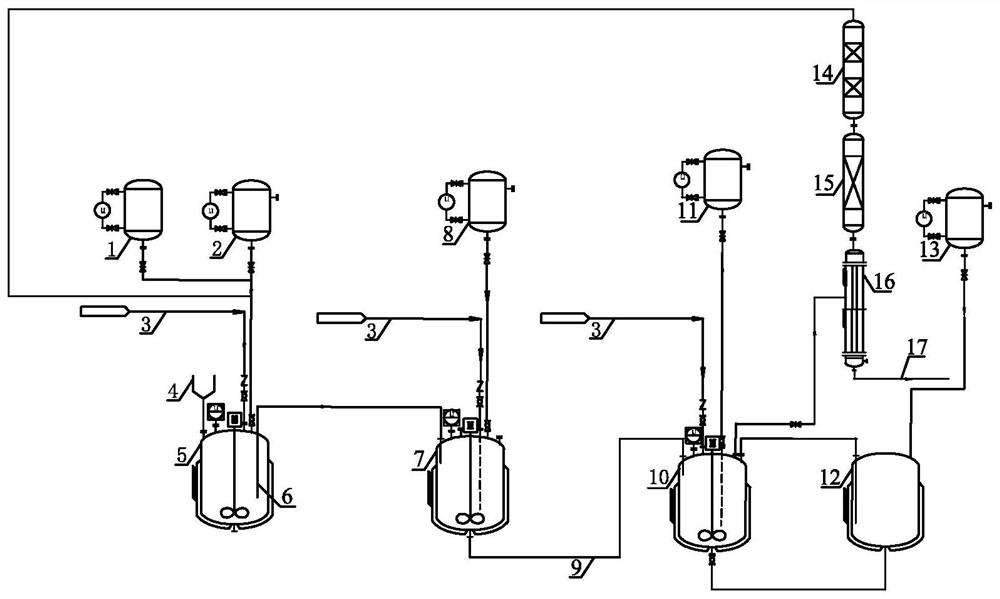

[0037] The device for preparing 5-tert-butyl-5-hydroxy-1,3-diphenyl-2,4-imidazolidinedione according to the present invention includes a Grignard reagent kettle 5, and the Grignard reagent kettle 5 passes through the pipeline It is connected to the Grignard reaction kettle 7, the quenching kettle 10 and the extraction kettle 12 in sequence, and the top of the quenching kettle 10 is connected to the distillation tower 16, the anhydrous calcium chloride drying tower 15 and the molecular sieve drying tower 14 in sequence through pipelines, and the distillation tower 16 The lower discharge port is connected to the discharge pipe 17, and the top of the molecular sieve drying tower 14 is connected to the Grignard reagent kettle 5 through a pipeline.

[0038] The feed inlet at the upper end of the Grignard reagent kettle 5 is connected to the tert-butyl chloride metering tank 1, the solvent tank 2, the low-pressure nitrogen delivery pipe 3, and the outlet of the magnesium scrap feedin...

Embodiment 1

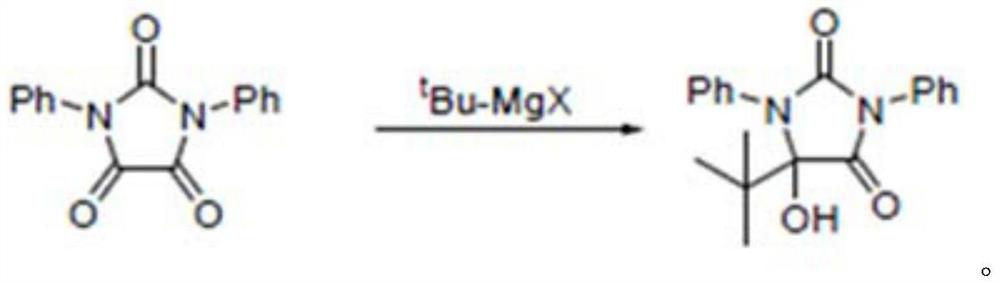

[0046] The continuous cycle industrial production method of 5-tert-butyl-5-hydroxyl-1,3-diphenyl-2,4-imidazolidinedione described in Example 1 consists of the following steps:

[0047] (1) Preparation of Grignard reagent: under the protection of inert nitrogen gas and anhydrous conditions, the initiator of the prefabricated 5 liters of 1 mole per liter concentration is poured in 2000 liters of Grignard reagent kettle (conventional non-standard reaction kettle, volume 2 cubic, with the upper cover and neck about 2.3 cubic), then add 500 liters of anhydrous tetrahydrofuran and 15.6 kg of magnesium chips, slowly heat to 65 ° C to keep the reaction system slightly reflux, dropwise add tert-butyl chloride solution (52 kg of tert-butyl Chlorine is pre-dissolved in 500 liters of anhydrous tetrahydrofuran); the reaction is exothermic, and the slight reflux state in the kettle is maintained by adjusting the amount of heating steam in the reactor; after the dropwise addition, the reactio...

Embodiment 2

[0053] The continuous cycle industrial production method of 5-tert-butyl-5-hydroxyl-1,3-diphenyl-2,4-imidazolidinedione described in Example 2 consists of the following steps:

[0054] (1) Preparation of Grignard reagent: under the protection of inert nitrogen gas and anhydrous conditions, the initiator of the prefabricated 6.5 liters of 1 mole per liter concentration is poured in 2000 liters of Grignard reagent kettle (conventional non-standard reaction kettle, volume 2 cubic, plus the upper cover and neck about 2.3 cubic), then add 500 liters of anhydrous toluene and 14.9 kilograms of magnesium chips, slowly heat to 70 ° C to keep the reaction system slightly reflux, dropwise add tert-butyl chloride solution (52 kilograms of tert-butyl Chlorine is pre-dissolved in 500 liters of anhydrous toluene); the reaction is exothermic, and the slight reflux state in the kettle is maintained by adjusting the amount of heating steam in the reactor; after the dropwise addition, continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com