Fabricated wallboard and manufacturing method thereof

A prefabricated, wallboard technology, applied in the field of wallboard manufacturing, can solve the problems of long construction period, high cost, and unclean construction site for non-load-bearing walls, and achieve the effect of shortening construction period, reducing construction cost, and keeping the site clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The assembled wall panels and the manufacturing methods thereof proposed in the present invention and the manufacturing method thereof will be further described below with reference to the accompanying drawings and specific examples. The advantages and features of the present invention will be more clear depending on below. It is to be noted that the figures use a very simplified form and use non-precision ratios, only to convenient, clearly assisted in the purpose of explaining the embodiments of the present invention.

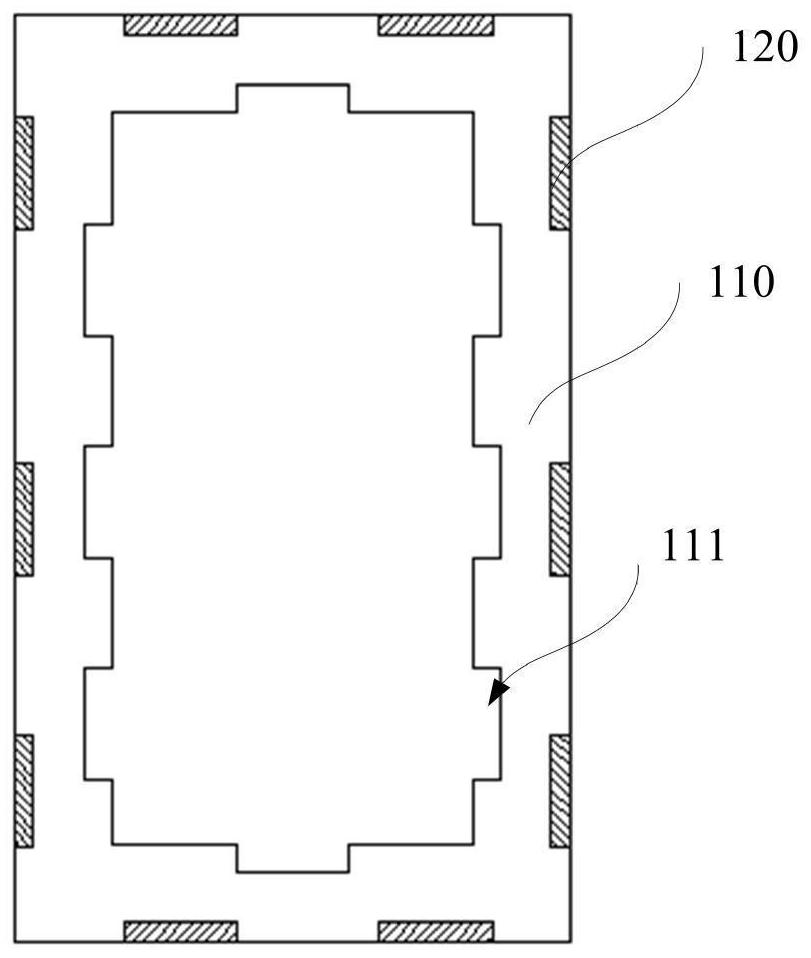

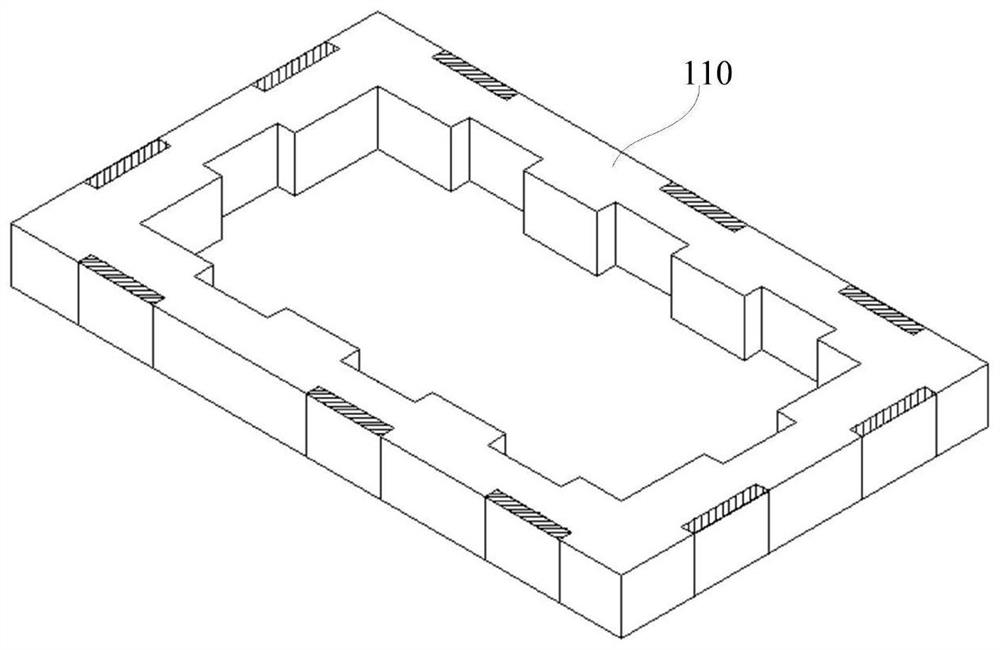

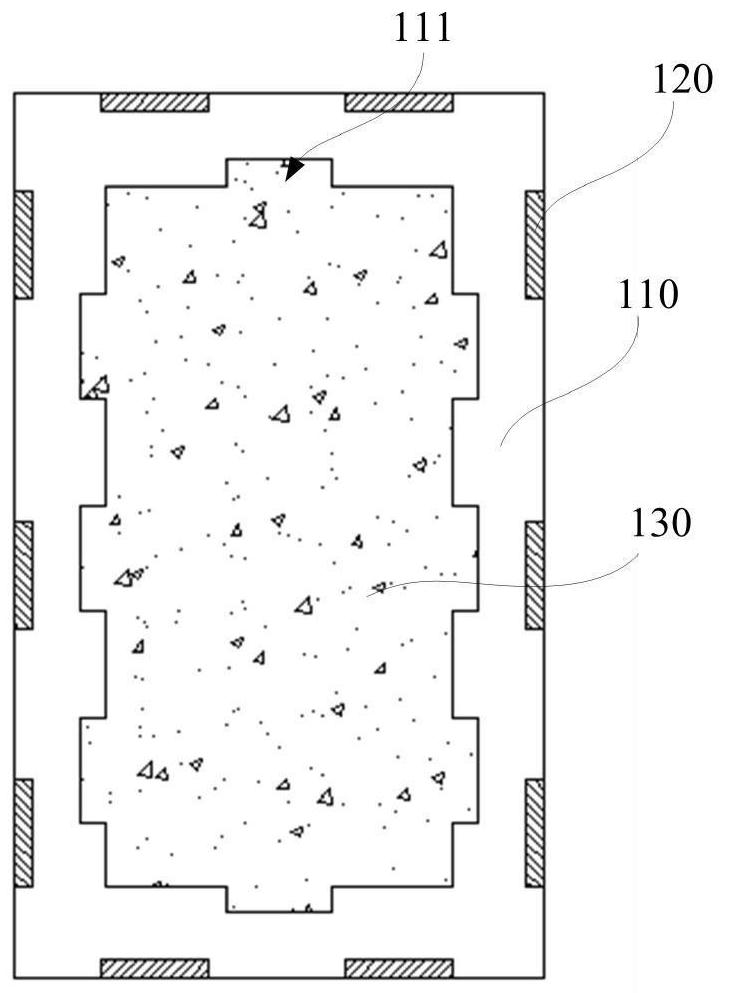

[0027]This embodiment provides an assembled wall panel. referencefigure 1 ,figure 2 ,image 3 withFigure 4 ,figure 1 It is a front view of the external frame 110 and the pre-buried steel plate 120 in the embodiment of the present invention,figure 2 Is a perspective view of the external frame 110 and the pre-buried steel plate 120 in the embodiment of the present invention,image 3 It is a schematic structural diagram of the prefabricated wall panel module 100 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com