Concrete cushion block

A technology for concrete pads and concrete blocks, which is applied in the directions of buildings, building reinforcements, building components, etc., can solve the problems of poor connection stability, lap failure, and relative displacement of concrete pads and steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

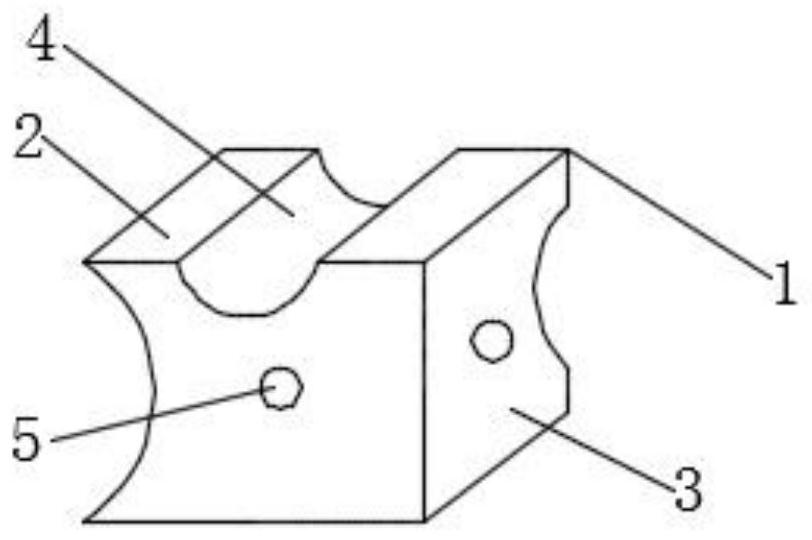

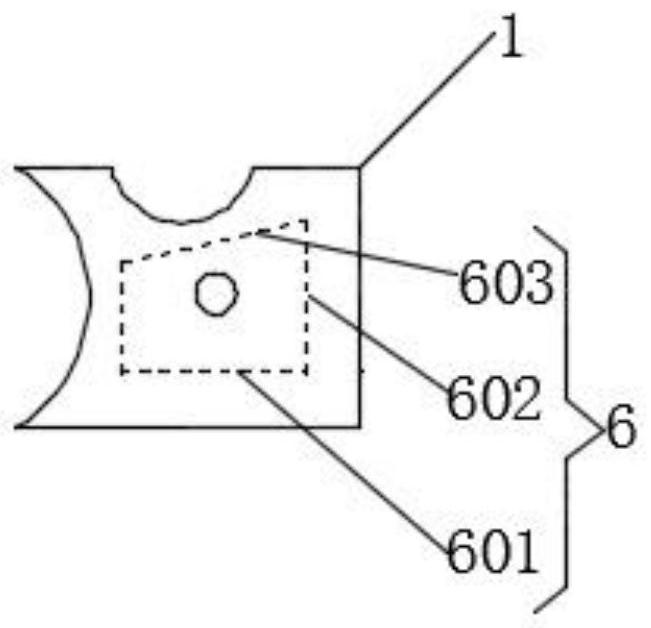

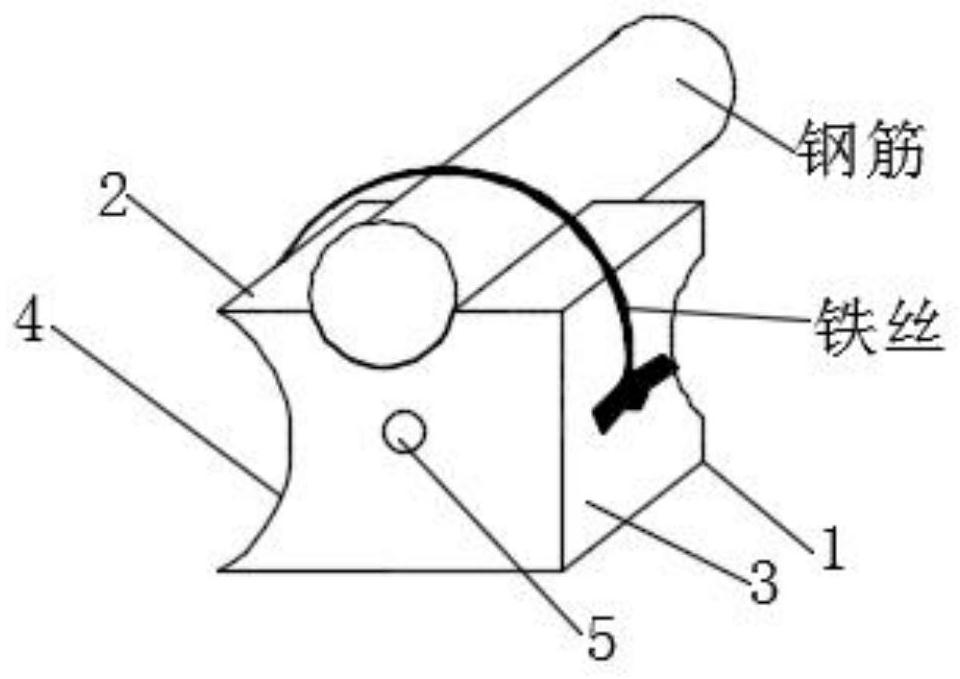

[0025] see Figure 1-5 , the present invention provides a technical solution: a concrete block, including a square concrete block 1, the square concrete block 1 is made of high-strength fine stone concrete, and has a strong resistance to damage, and the square concrete block 1 It is the main body of the concrete block. The six sides of the square concrete block 1 include three concave grooves 2 and three planes 3. The concave grooves 2 are provided with concave grooves 4. The concave grooves Shaped groove 4 is used for overlapping with steel bar, and the size of three described concave grooves is not equal, can be overlapped with the steel bar of different diameter, and practicability is strong, and described plane 3 is used for connecting with formwork, anti-displacement reinforcement The concrete pad is placed between the formwork and the steel bar as a whole, which is suitable for connecting the curved surface and the planar member, expanding the overlapping area between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com