Prefabricated unit assembly structure for large-volume underground structures

An underground structure and large-volume technology, applied in the field of substation construction, can solve problems such as inconvenient processing, transportation and hoisting, inability to realize prefabricated assembly, and affect the full assembly of substations, and achieve easy integrated processing, simple wet operation processing, The effect of saving the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

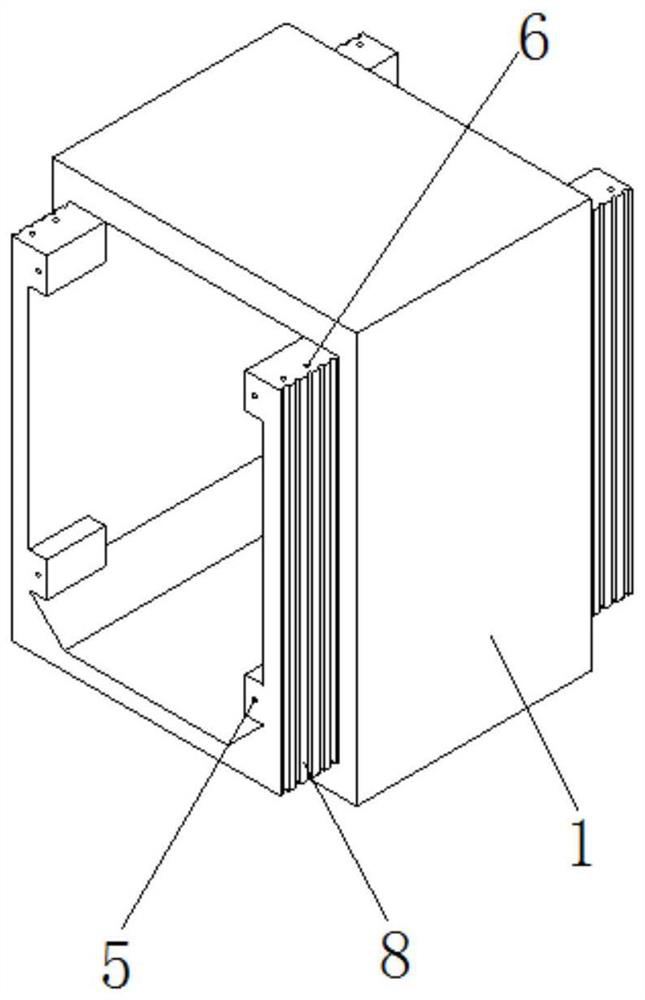

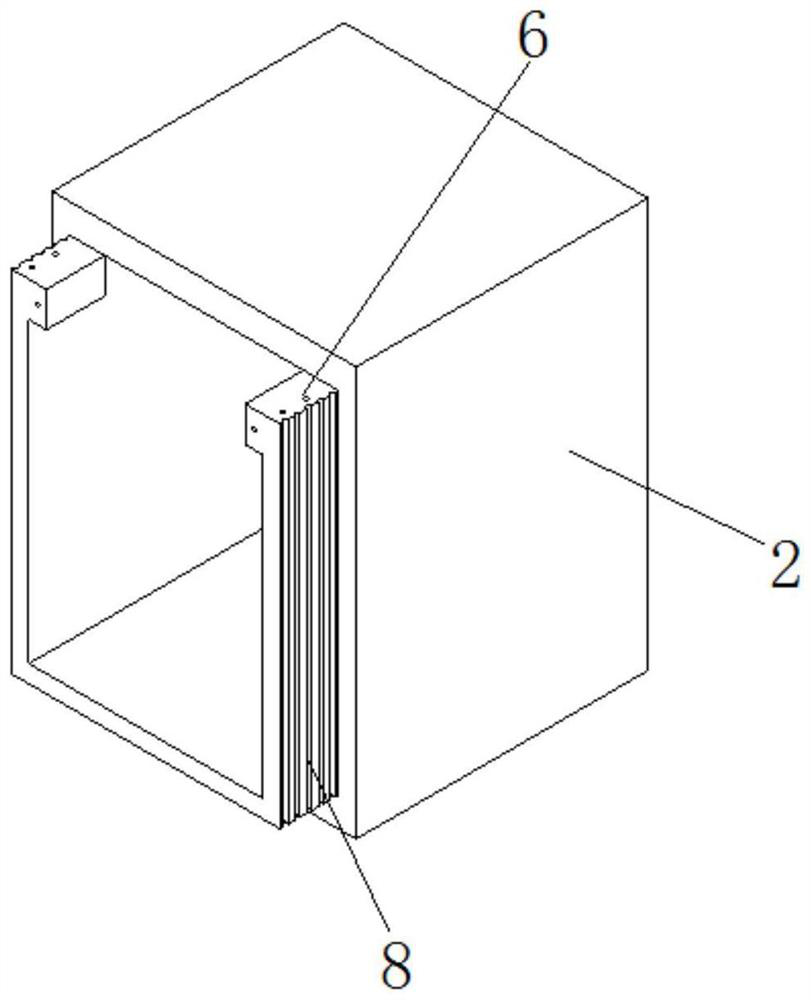

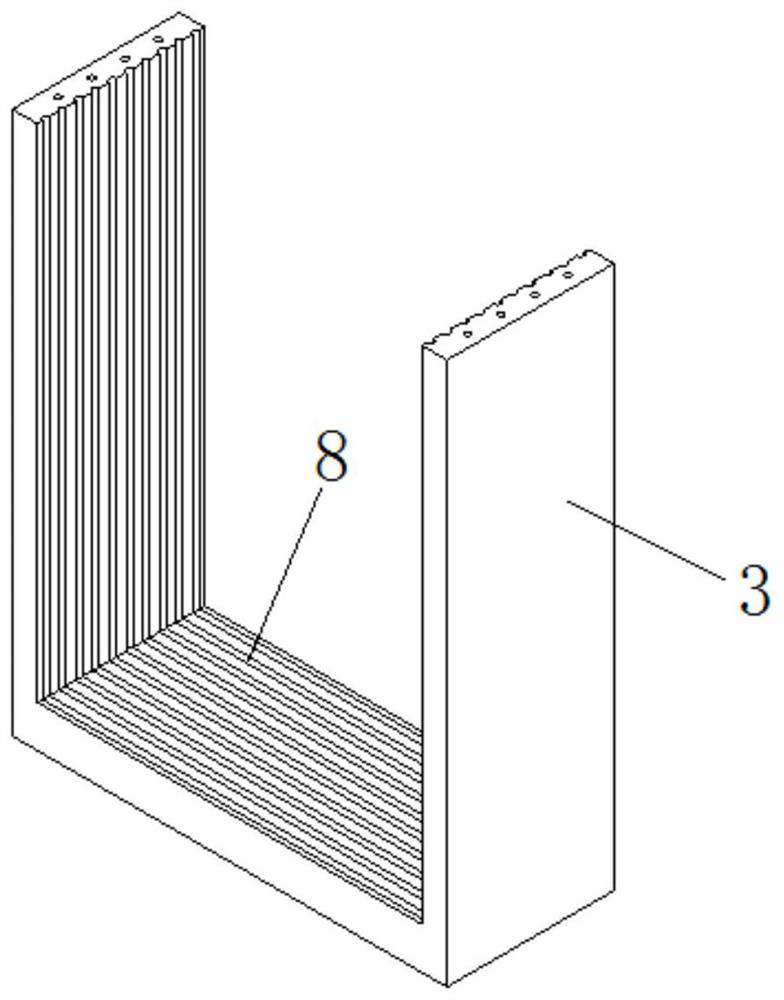

[0024] like Figure 1-Figure 5 As shown, a prefabricated unit assembly structure of a large-volume underground structure includes an intermediate unit 1, an end unit 2 and a connecting unit 3. The intermediate unit 1 and the intermediate unit 1, and the intermediate unit 1 and the end unit 2 pass through the connecting unit 3 respectively. After assembling, a first grouting hole 7 is formed;

[0025] The middle unit 1, the end unit 2 and the connecting unit 3 are fixedly connected by horizontal positioning bolts 5. The connection between the middle unit 1, the end unit 2 and the connecting unit 3 is covered with an upper cover 4, which is The joints are fixedly connected by vertical fastening bolts 6 , and a second grouting hole 41 is reserved at the position of the upper cover plate 4 corresponding to the first grouting hole 7 .

[0026] Specifically, the intermediate unit 1, the end unit 2, and the connecting unit 3 are respectively provided with grouting grooves 8. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com