Telescopic gas extraction pipeline device

A gas pipe and telescopic technology, which is applied in the field of telescopic gas pumping pipeline devices, can solve the problems of gas exceeding the limit, and achieve the effect of saving equipment and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

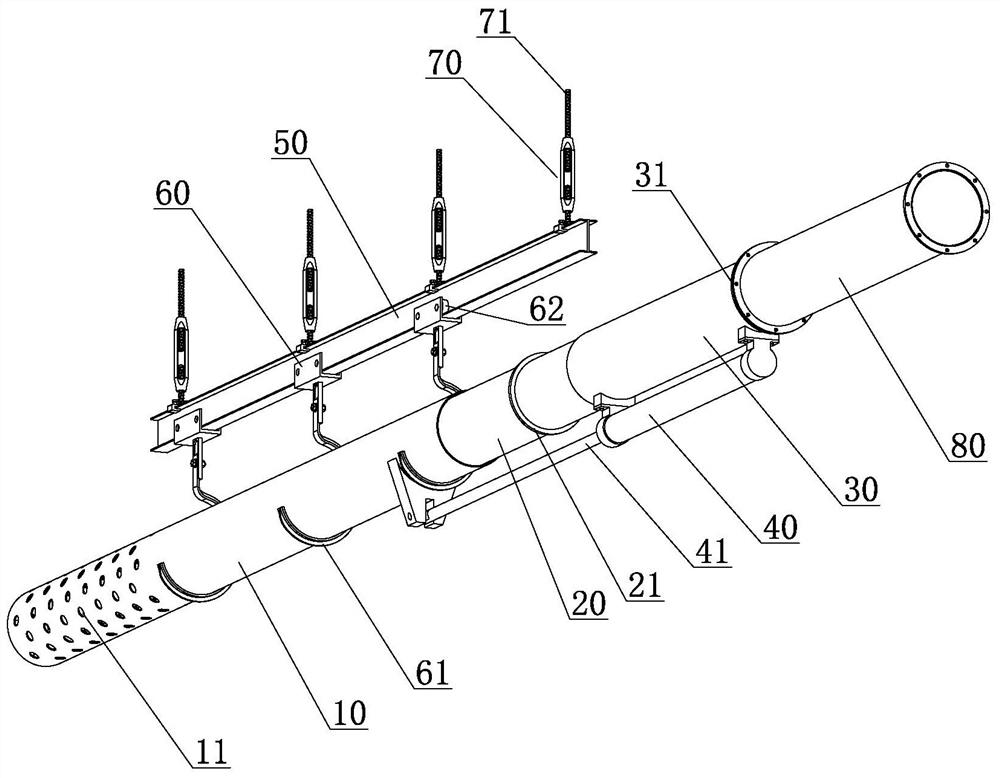

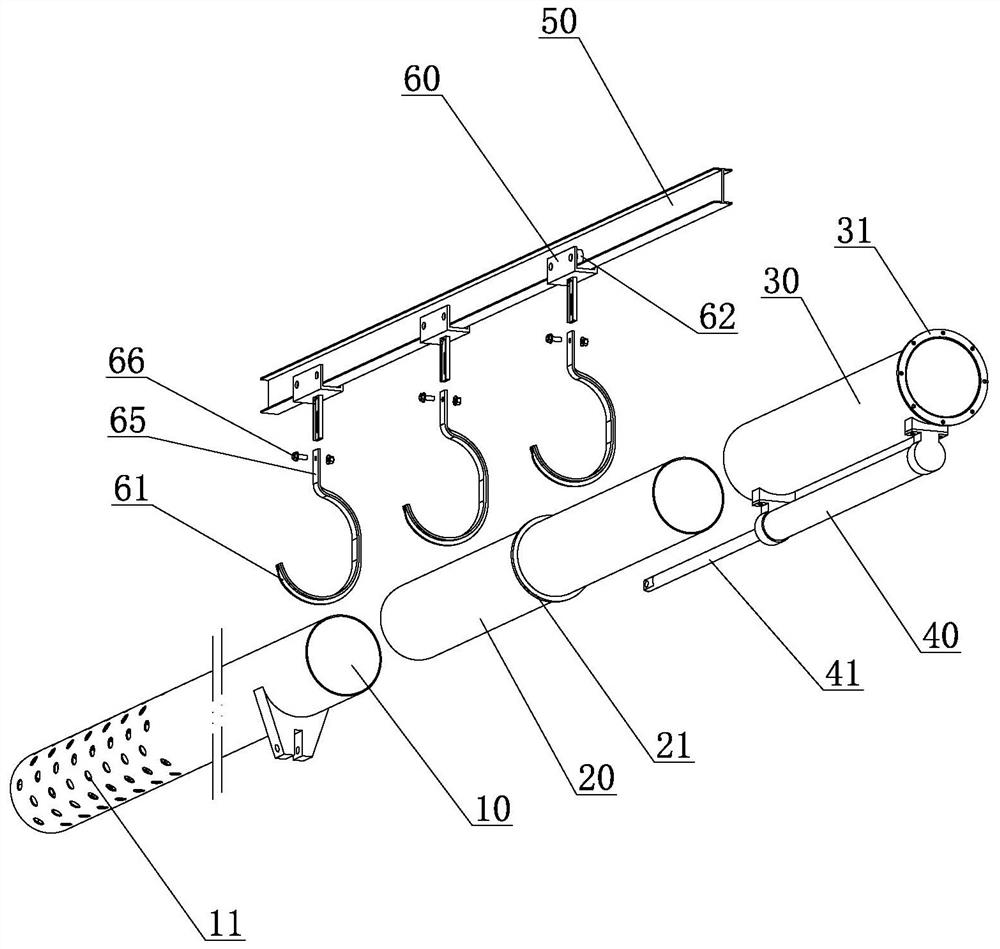

[0033]Such asFigure 1 to 5, A telescopic tuning pipeline device comprising a pumping drag tube 10, a telescopic pipe 20, and a base tube 30.

[0034]The pumping drag 10 is a steel pipe of 377 x 6 (outer diameter 377 mm, wall thickness, and a front end of the pumping drag tube, i.e., a plurality of vent hole 11 is provided.

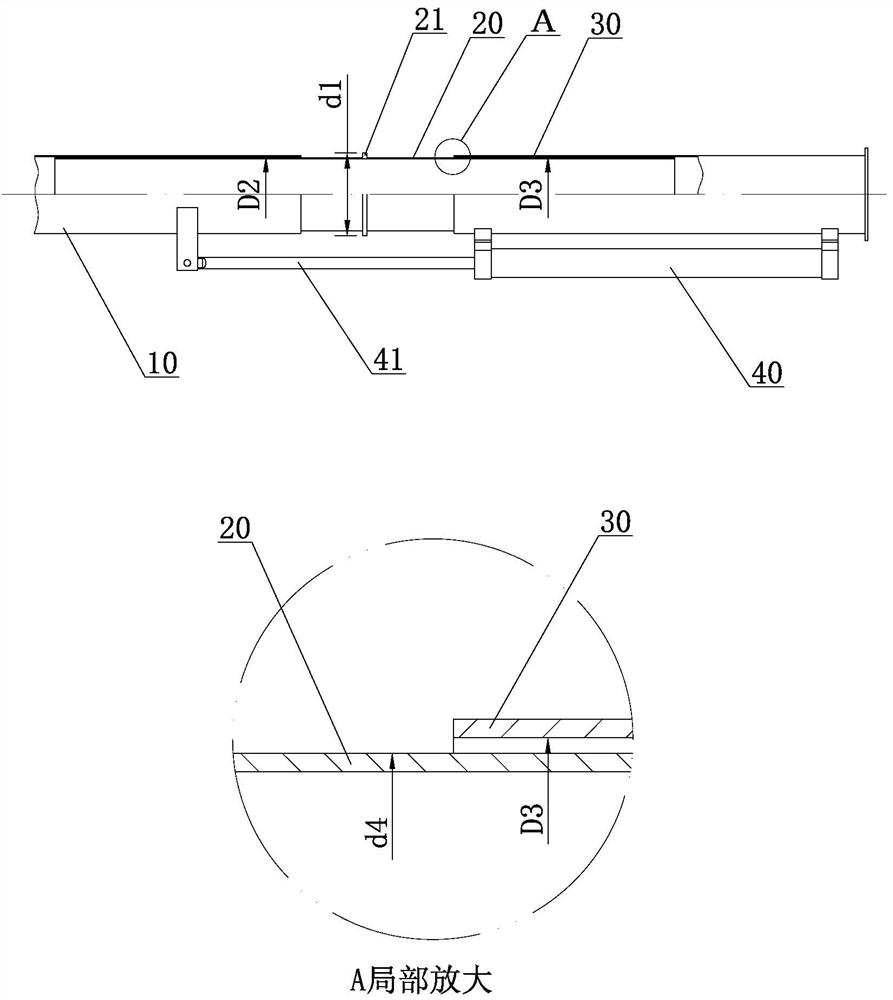

[0035]The telescoping pipe 20 is a steel pipe of 355 × 6 (outer diameter 355 mm, wall thickness 6 mm), and the outer diameter of the telescoping pipe is provided with a stop flange 21, and the stop flange is disposed in the middle of the telescoping pipe.

[0036]The base tube 30 is the same as the specification of the pumping drag, and is also a steel pipe of 377 × 6 (377 mm, wall thickness of 6 mm). The inner diameter D2 of the base tube is the same as the inner diameter D3 of the pumping drag.

[0037]The rear end of the base tube is provided with a connection flange 31, and the base tube is attached to the gasteat pipe connection through the connection flange 31. The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com