A variable-load extraction pipeline and extraction method based on the principle of catalytic denaturation

A drainage pipe and extraction technology, applied in mining equipment, earthwork drilling, gas discharge, etc., can solve problems such as lack of efficiency, safety, working face personnel, hidden dangers of equipment safety, crowded underground working face, etc. Achieve the effect of saving work space and materials, reducing safety management costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

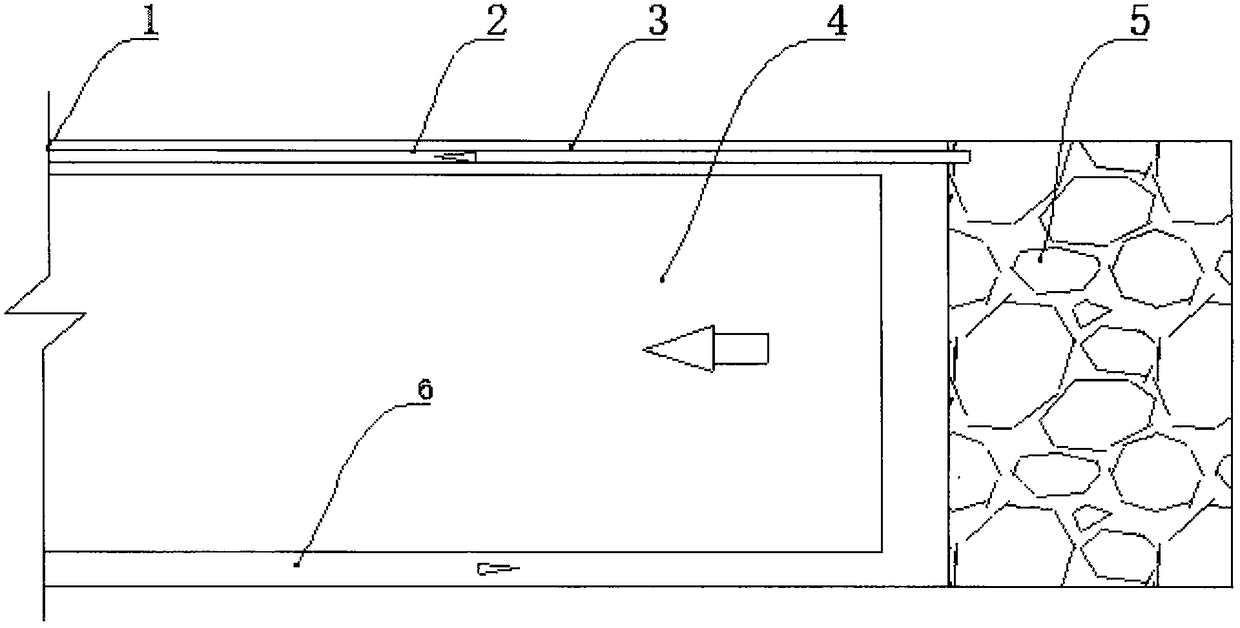

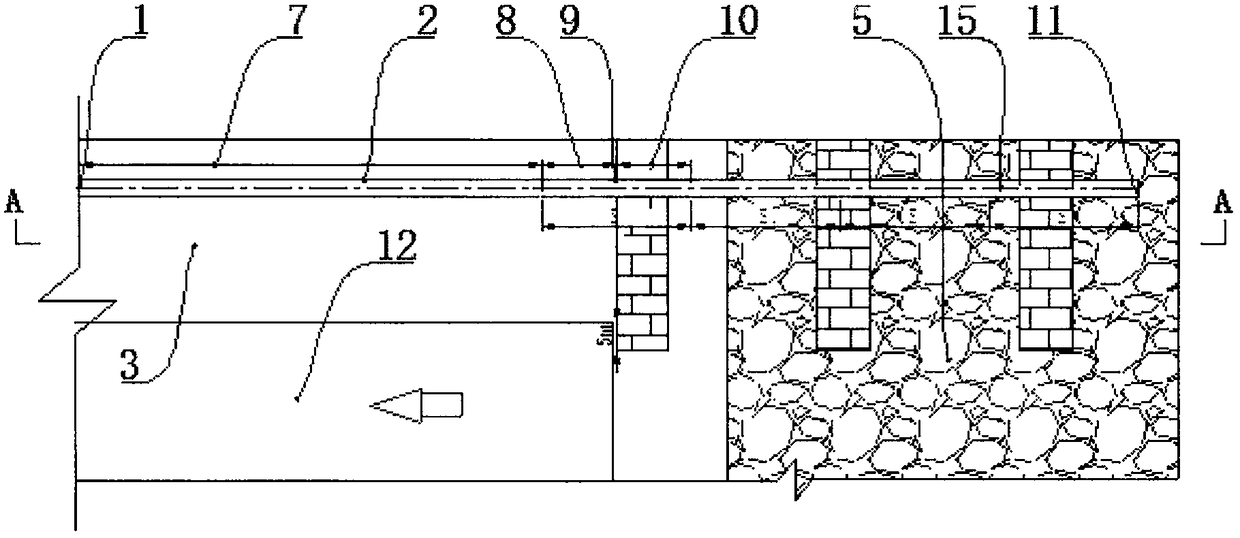

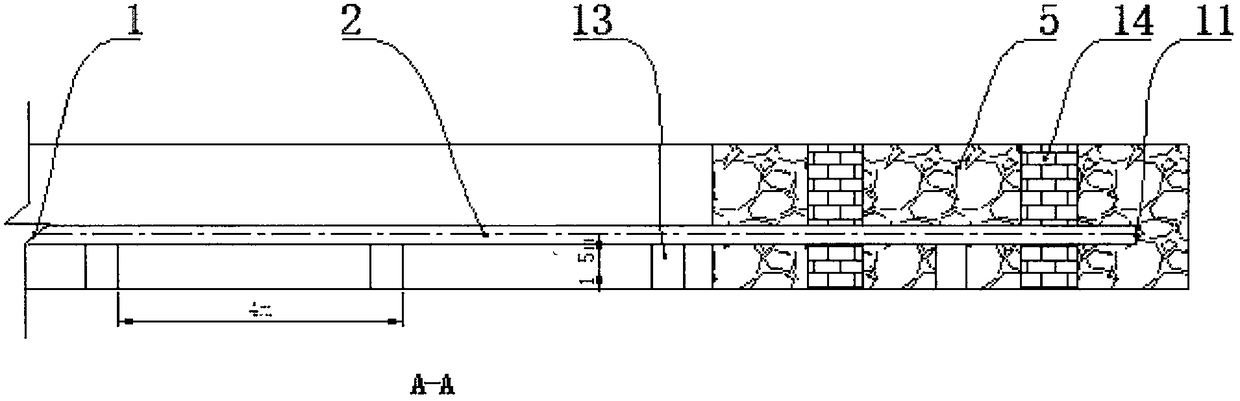

[0036] When the present invention is implemented, after the recovery working face 4 is formed, the variable load extraction pipeline 2 is pre-laid in the air return lane 3, and the distance between the variable load extraction pipeline 2 and the bottom plate 12 of the air return lane is 1.5m. The spacing is 4m. During the normal production of mining face 4, a group of bag walls 1414 with a width of 3m are constructed at intervals of 1.5Sm, and T 2 Apply deloading catalyst in decay section 10, after T 1 day attenuation, the compressive load of attenuation section 10 is reduced to P 2 , the compressive load of the transition section 8 is reduced to P 3 , the compressive load of the original section does not change to P 1 , the force P on the roof collapse 4 Under the action, the attenuation section 10 is broken, and the support frame 13 automatically becomes the next extraction port. In the whole process, except for manually applying the load-reducing catalyst in advance, the...

Embodiment 2

[0038] In the embodiment of the present invention, it is only necessary to focus on monitoring the roof cycle of the working face to press the step distance value S, and determine the decay time T according to the S value and in combination with the daily advancing degree L of the working face 2 , when there is no roof cycle pressure step value for the working face at the initial stage of mining, refer to the data of the adjacent working face (under normal circumstances, the adjacent working face with the same mining technology; the change of the roof cycle pressure step distance is small), After the actual measurement conditions are corrected, the invention has the continuity, scientificity, safety and high efficiency of gas drainage, can save the working space and materials of the working face, liberate part of the labor force, reduce the cost of safety management, and greatly improve the production efficiency of the working face The advantages. Other settings are the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com