Production line for detecting foreign matters in bottles

A foreign matter detection and production line technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems affecting the detection effect, and achieve the goal of ensuring the detection effect, improving the detection effect, and preventing missed detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

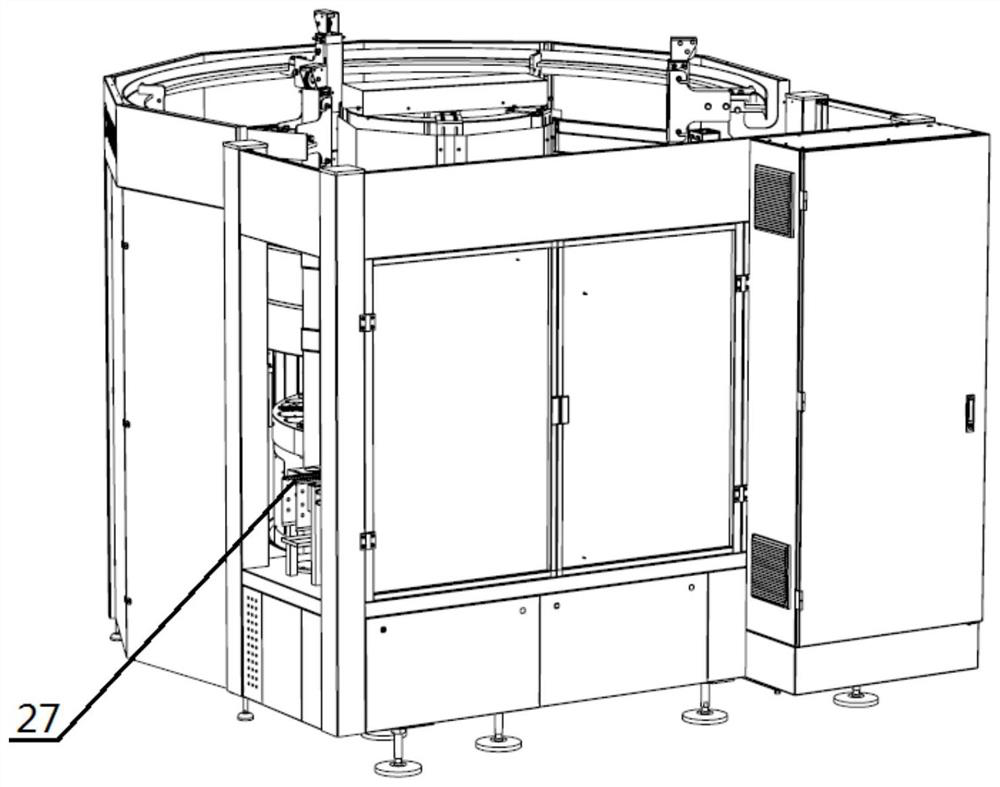

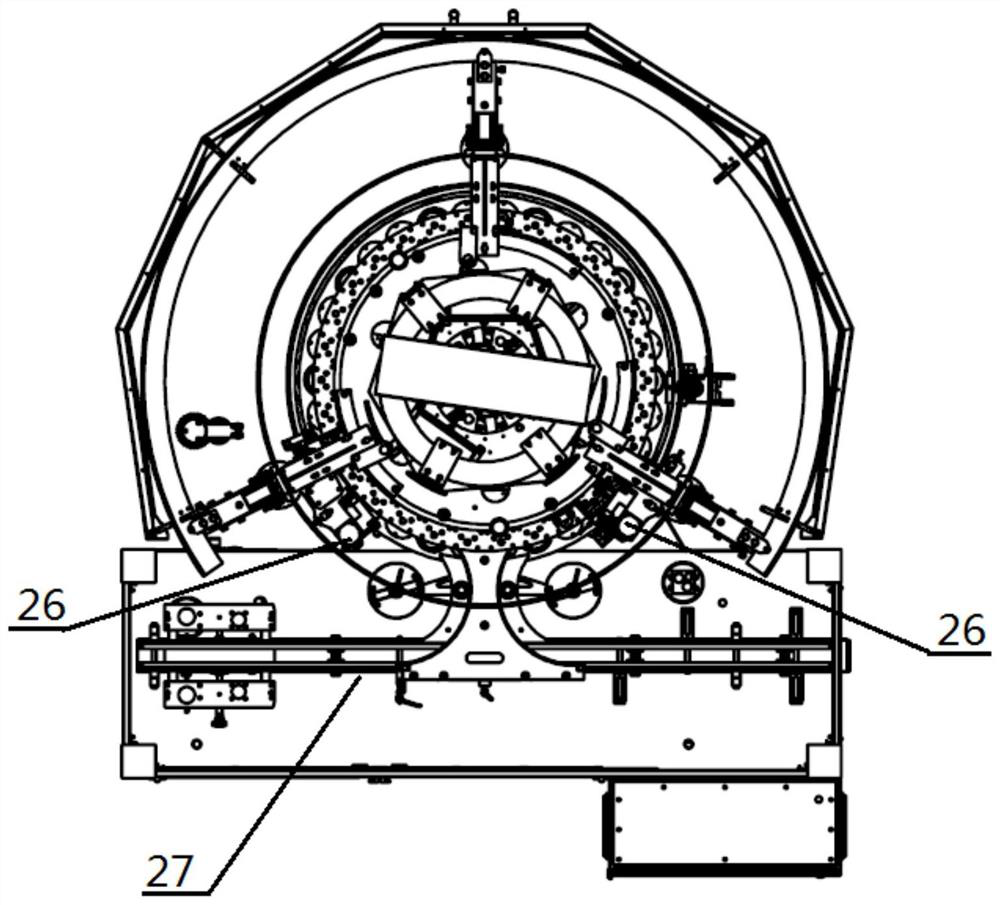

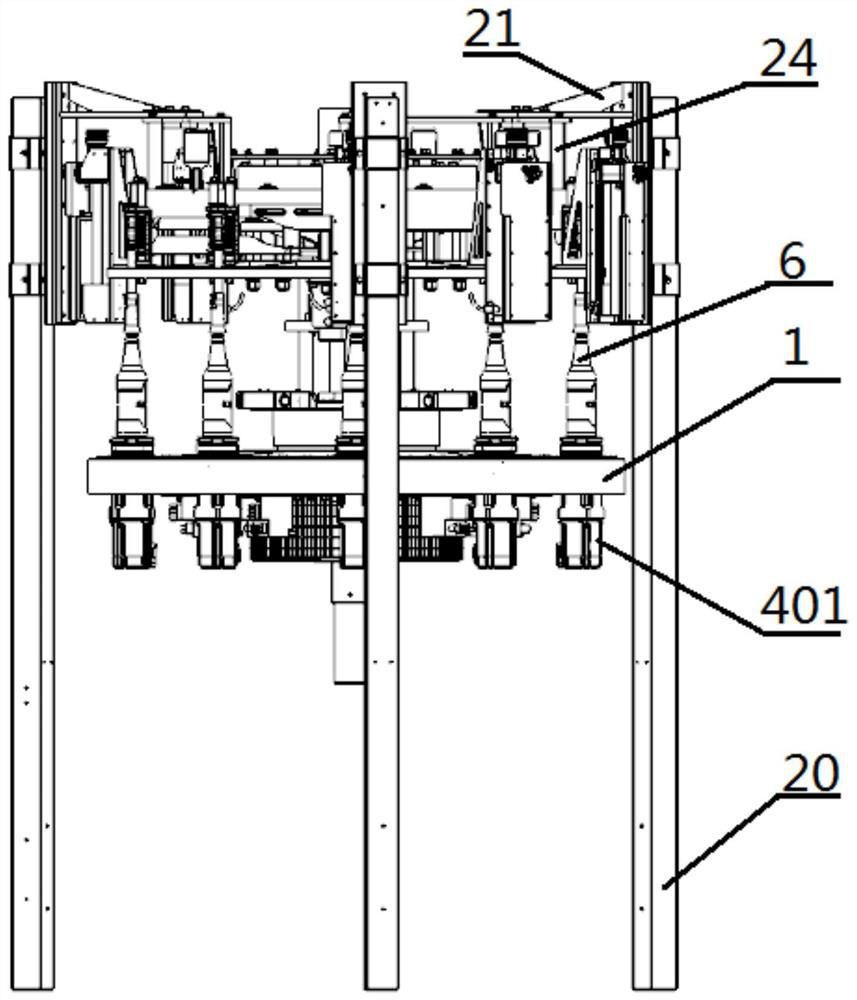

[0024] The following is attached figure 1 To attach Figure 11 The principles and features of the present invention are described, and the examples given are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0025] A production line for detection of foreign objects in bottles, including a turntable 1, a pressure plate 2, several detection terminals 3, several detection stations 4, several pressing rods 5, a transmission shaft 7, a light source board 8, a first lifting assembly 9, and a second lifting assembly 10. Cam 11, fixed seat 12, sliding sleeve 13, slewing bearing 14, transition sleeve 15, tray 16, pull key 17, fixed plate 18, support column 20, support arm 21, locking sleeve 22, connecting column 23, connecting column Rod 24 and expansion sleeve 25.

[0026] The turntable 1, the fixed seat 12, the pressure plate 2, and the sliding sleeve 13 are arranged in parallel and spaced order from bottom to top, and are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com