SMT printing process burst buckle jig

A printing process and fixture technology, which is applied in the direction of assembling printed circuits with electrical components and forming conductive patterns, etc., which can solve problems such as poor printing, waste of cost, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In order to make the objects, technical solutions and advantages of the present invention, the invention will be further described in detail below with reference to the embodiments. The specific embodiments described herein are for explaining the invention and is not intended to limit the invention.

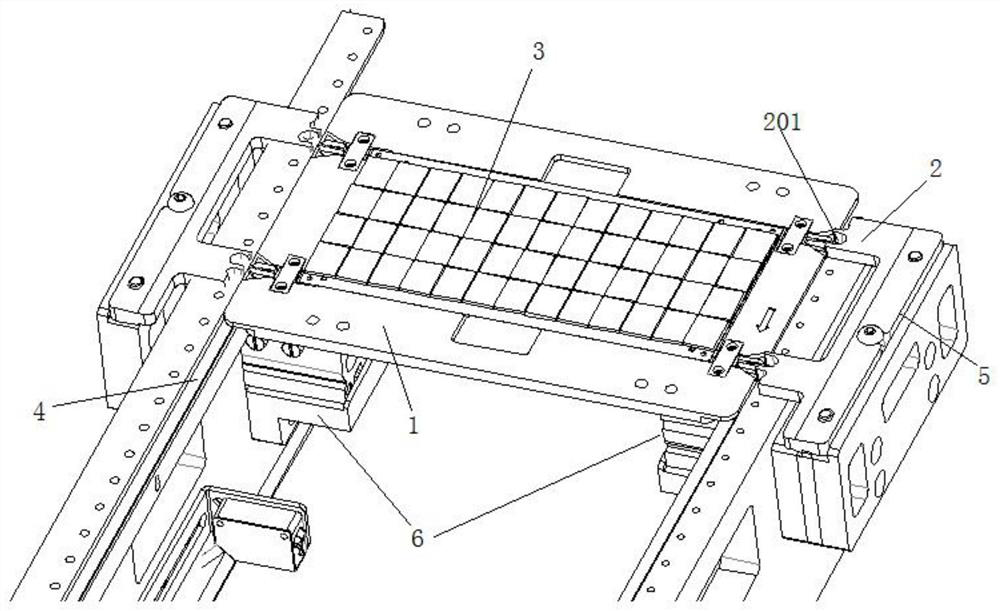

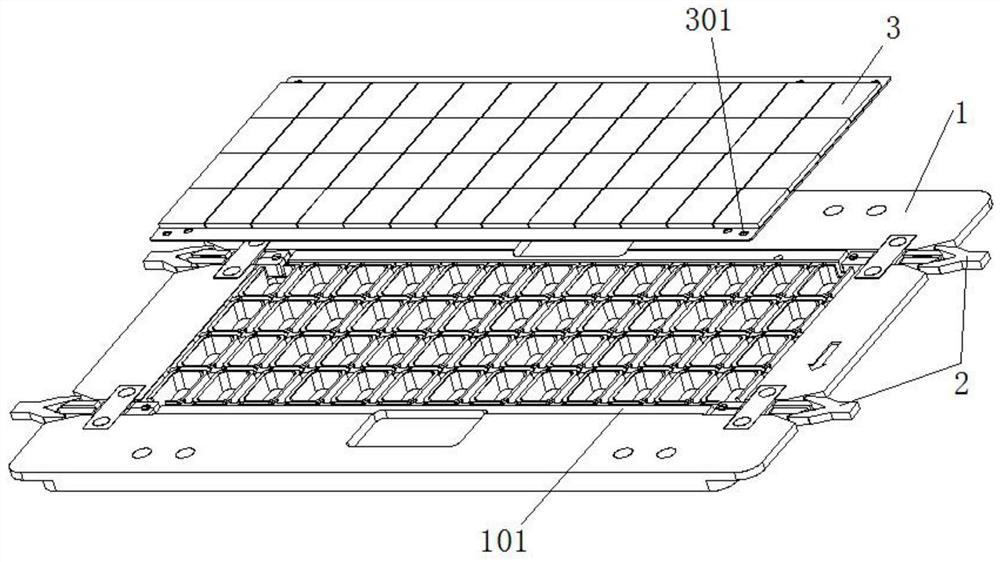

[0024]Such asFigure 1 - Figure 3As shown, the SMT printing process buckle assignment of the present embodiment includes a trigger body 1 disposed on the frame 4, and the fixture body 1 is a recess 101 for placing the PCB plate 3, the PCB plate. The four corners of the 3 have a positioning aperture 301, and a set of positioning mechanisms for tightening the positioning hole 301 on the PCB plate is provided on both ends of the groove 101, each set of positioning mechanisms including two. Symmetric distribution buckle mechanism.

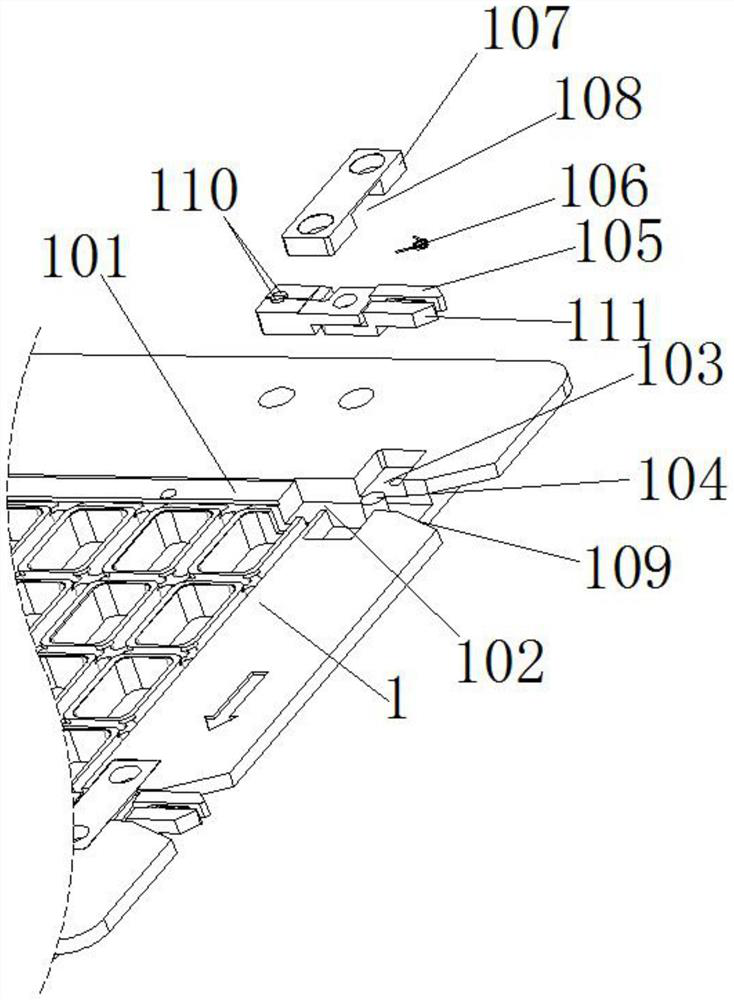

[0025]Specifically, such asfigure 2 ,image 3 As shown, the bursting mechanism includes a first mounting groove 102, a second mounting groove 103, two active jaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com