Sealing structure of rotary swing mechanism of vertical roller mill

A technology of sealed structure and vertical roller mill, which is applied in the direction of grain processing, etc., can solve the problems of inconvenient maintenance, fast wear, affecting equipment energy consumption and output, etc., and achieves the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

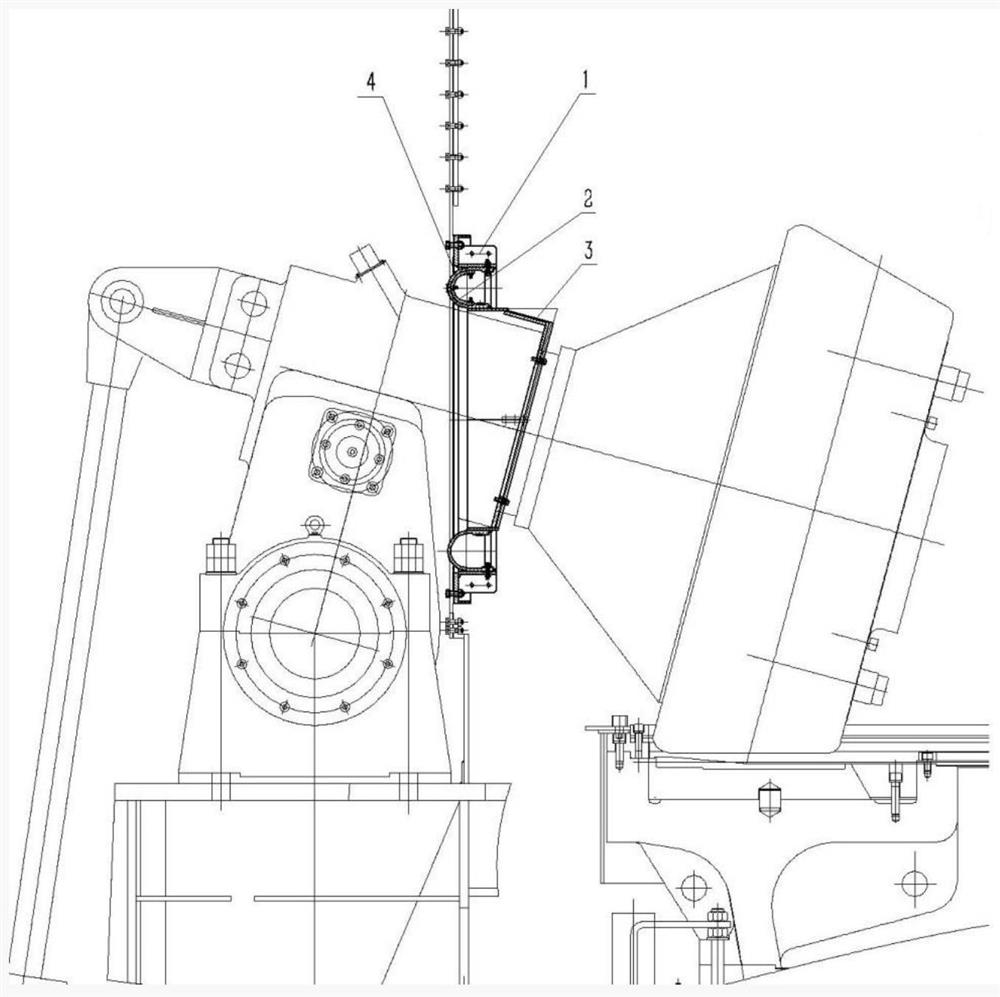

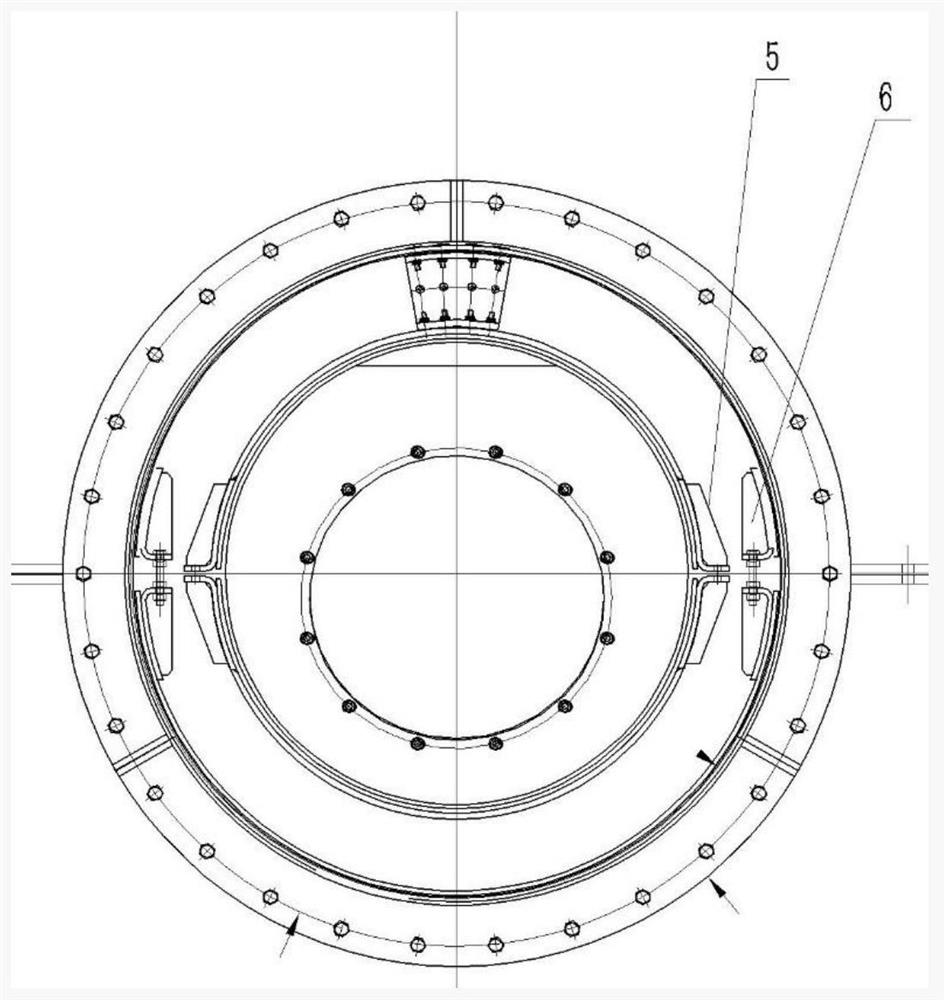

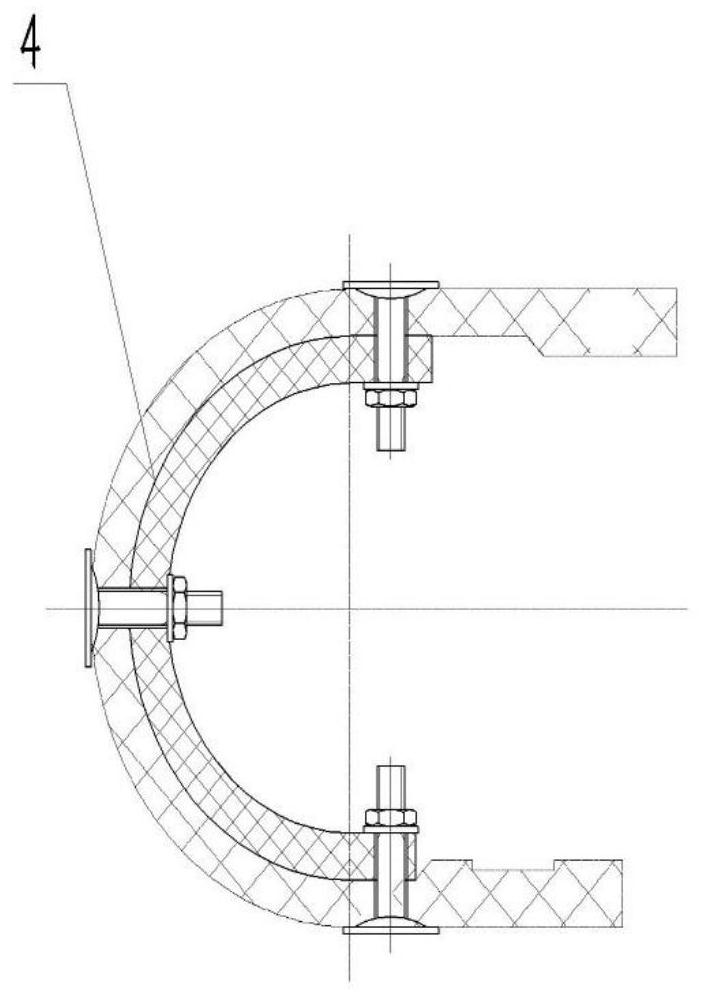

[0018] Such as figure 1 As shown, the present invention discloses a sealing structure of a vertical roller mill rotary swing mechanism, including an installation outer cylinder 1 fixedly installed on the vertical roller mill shell, an installation cylinder 1 fixedly installed on the vertical roller mill rotary swing mechanism The inner cylinder 3 and the C-shaped sealing ring 4 arranged between the installation outer cylinder 1 and the installation inner cylinder 3, through which the C-shaped sealing ring 4 can ensure that the installation outer cylinder 1 is rotated in the vertical roller mill. The oscillating mechanism is fixed du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com