A clamping device and clamping method

A clamping device and clamping technology, applied in the field of grinding machines, can solve the problems of overturning and scattering of samples in grinding bowls, burning fingers or high-altitude injuries, affecting the quality of sample detection, etc., to avoid pollution, avoid potential injuries, Reduce the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

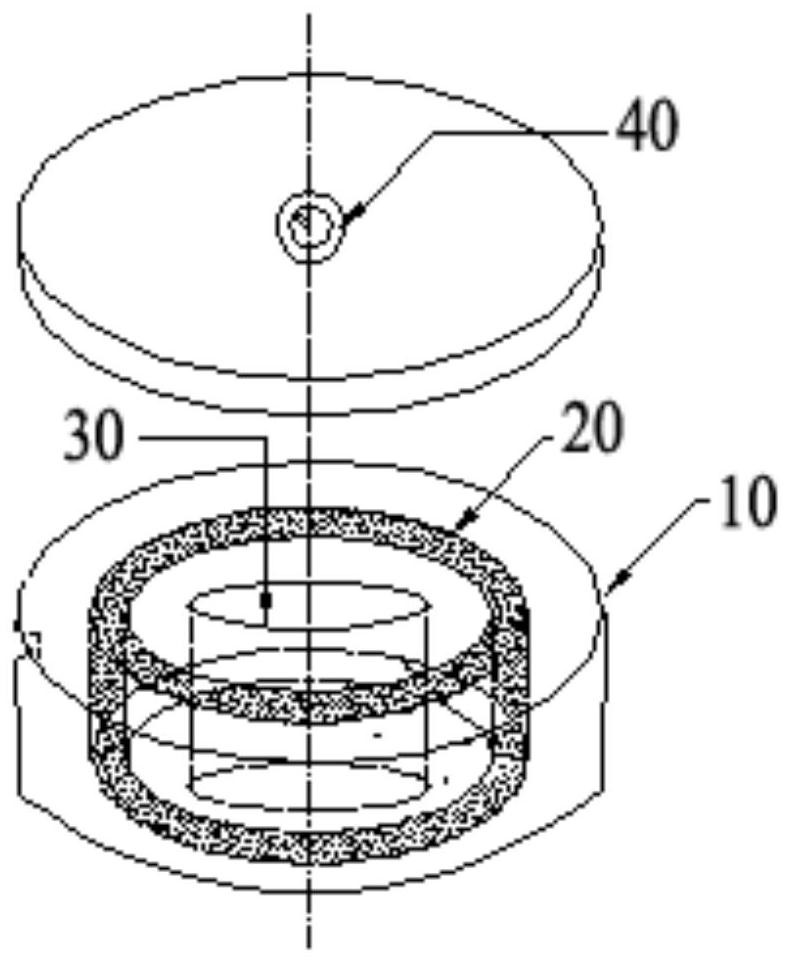

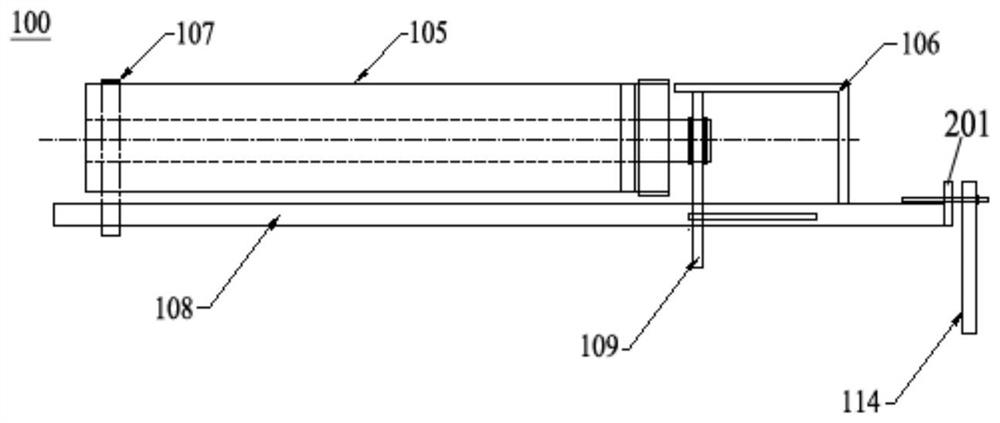

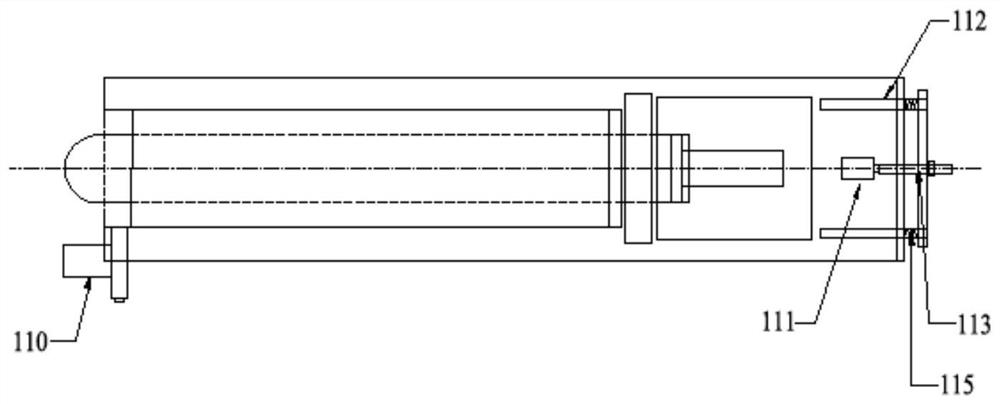

[0049] The present application proposes a clamping device 100 based on a grinding machine, which is used to clamp components in the grinding machine, mainly to operate the grinding bowl (mainly referring to the grinding core) in the grinding machine.

[0050] In order to facilitate understanding of the working principle and usage of the clamping device 100 , the structure of the grinding bowl is given below, and the description of the clamping device 100 in the present application will be developed based on the structure.

[0051] Furthermore, it should be noted that although the examples of the present application are described based on a grinding bowl, this is not intended to limit the clamping device 100 in the present application to only be applicable to a grinding bowl. According to different needs, the clamping device 100 in the present application can also be used in different fields to clamp different objects. For example, rod-shaped objects, blocks, spherical objects ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com