Clamping device and clamping method

A clamping device and clamping technology, applied in the field of grinding machines, can solve the problems of overturning and scattering of grinding bowl samples, burning fingers or high-altitude smashing, and affecting the quality of sample testing, so as to avoid pollution, avoid potential injuries, Reduce the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

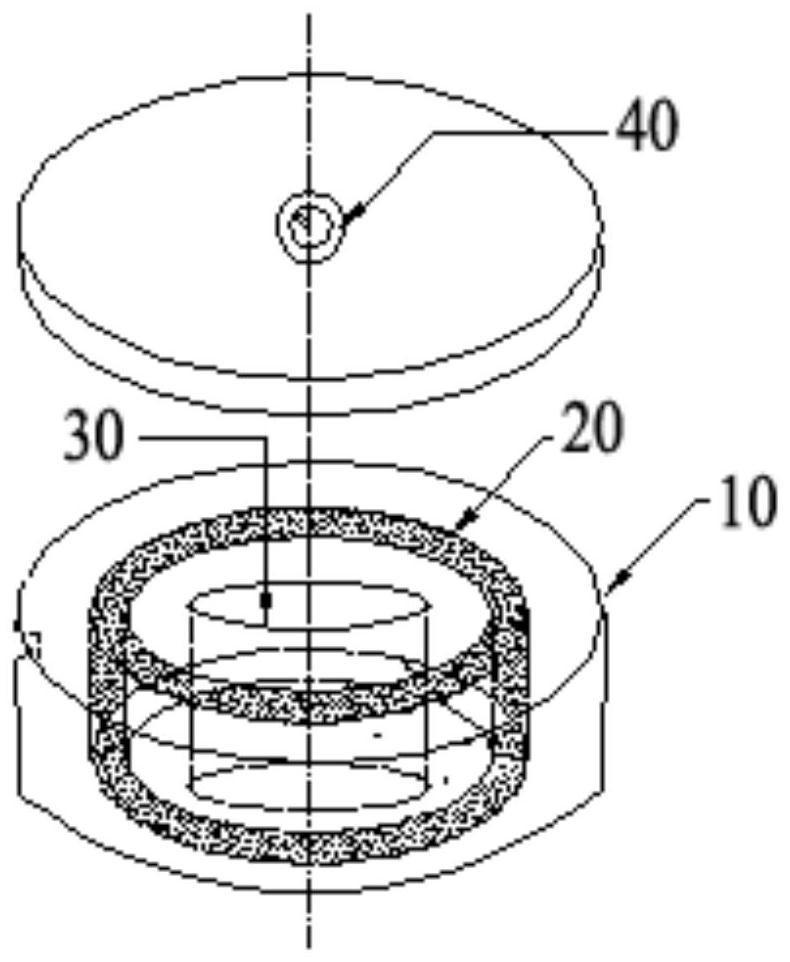

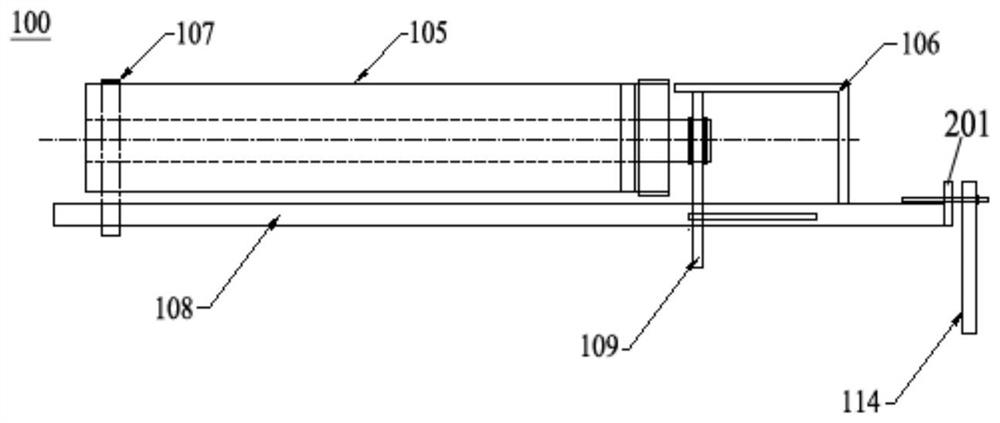

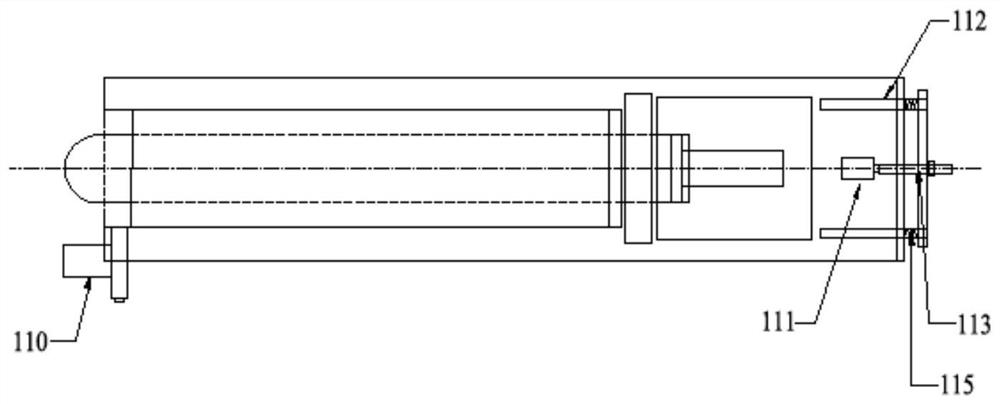

[0049] Based on the grinding machine, this application proposes a clamping device 100 for clamping the components in the grinding machine, mainly operating the grinding bowl (mainly referring to the grinding core) in the grinding machine.

[0050] In order to facilitate understanding of the working principle and usage of the clamping device 100 , the structure of the mortar is given below, and the description of the clamping device 100 in the present application is developed based on it.

[0051] Moreover, it should be noted that although the example of the present application is described based on a mortar, this is not intended to limit that the clamping device 100 in the present application can only be applied to a mortar. According to different requirements, the clamping device 100 in this application can also be used in different fields to clamp different objects. For example, the clamping device 100 can also clamp rods, blocks, spheres or frame-structured objects or the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com