A kind of prefabricated structure intelligent sleeve grouting device and construction method

A sleeve grouting and prefabricated technology, which is applied to measuring devices, building structures, processing of building materials, etc., can solve problems such as affecting the quality of sleeve grouting, difficult to detect grouting quality, and difficult to visually detect construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

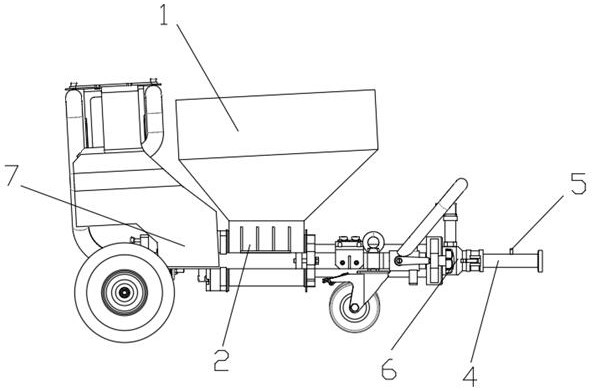

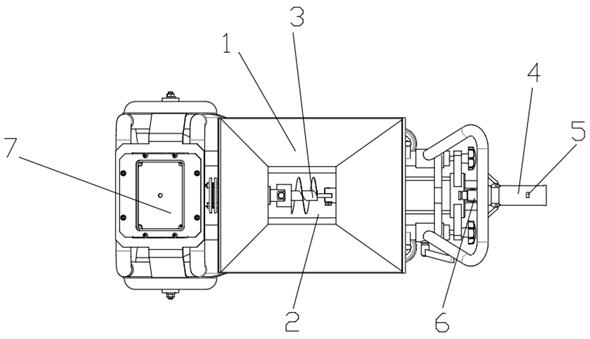

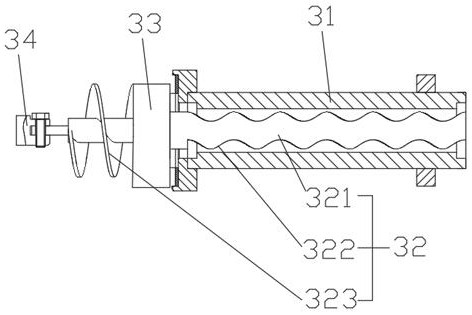

[0037] refer to Figure 1 to Figure 3 , the technical scheme of a prefabricated structure intelligent sleeve grouting device of this embodiment is as follows:

[0038] An assembled structure intelligent sleeve grouting device, comprising a hopper 1, a material box 2, a screw pump 3, a grouting pipe 4, a pressure sensor 5, and a flow meter 6; the material box 2 is connected to the outlet of the hopper 1; the The screw pump 3 is arranged inside the material box 2, and the grout outlet of the screw pump 3 extends out of the material box 2; the grouting pipe 4 is connected with the grout outlet of the screw pump 3; the pressure sensor 5 is arranged on the grouting pipe 4; the flow meter 6 is set between the screw pump 3 and the grouting pipe 4.

[0039] An intelligent sleeve grouting device with an assembled structure in this embodiment, when in use, the slurry is injected into the material box 2 from the outlet of the hopper 1, and is discharged from the grouting pipe 4 through ...

Embodiment 2

[0048] This embodiment provides a construction method for the prefabricated structure intelligent sleeve grouting device described in Embodiment 1, including the following steps:

[0049] S1, inject the slurry into the material box 2 through the hopper 1, start the screw pump 3 in the forward direction, grout the sleeve a of the assembled structure, and detect the flow rate and pressure of the slurry during the grouting process in real time through the pressure sensor 5 and the flow meter 6;

[0050] S2, set a blocking state judging pressure P1, the pressure of the slurry exceeds the blocking state judging pressure P1 and the flow rate of the slurry becomes smaller, repeatedly start the screw pump 3 forward and reverse several times, and then continue to start the screw pump 3 in the forward direction. The sleeve a of the structure is grouted;

[0051] S3, when the cumulative grouting amount of the flowmeter 6 reaches the required grouting amount of the sleeve a, the grouting ...

Embodiment 3

[0057] refer to figure 1 , figure 2 , Figure 4 , Fig. This embodiment provides another construction method for an assembled structure intelligent sleeve grouting device, including the following steps:

[0058] S1, dock the grouting port of the grouting pipe 4 with the grouting port of the sleeve a, connect the third port of the tee 14 with the grouting port of the sleeve a; open the first valve 8 and the second valve 9; Close the third valve 10, the pumping device 12;

[0059] S2, inject the slurry into the material box 2 through the hopper 1, start the screw pump 3 in the forward direction, grout the sleeve a of the assembled structure, and detect the flow and pressure of the slurry during the grouting process in real time through the pressure sensor 5 and the flow meter 6;

[0060] S3, when the sleeve a is blocked, close the first valve 8 and the second valve 9; open the third valve 10 and the pumping device 12;

[0061] S4, when the sleeve a is unblocked, reopen the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com