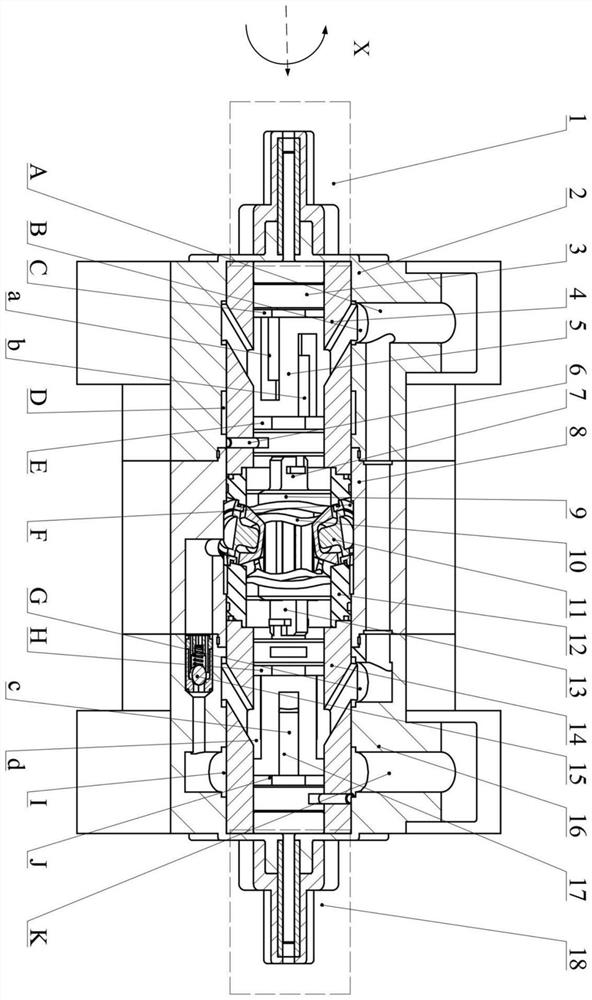

Rolling duplex two-dimensional piston type dynamic flowmeter

A dynamic flow, piston-type technology, applied in the field of flow meters, can solve the problems of dynamic flow reading hysteresis, etc., and achieve the effects of improving flow measurement accuracy, fixing firmly, and high response frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

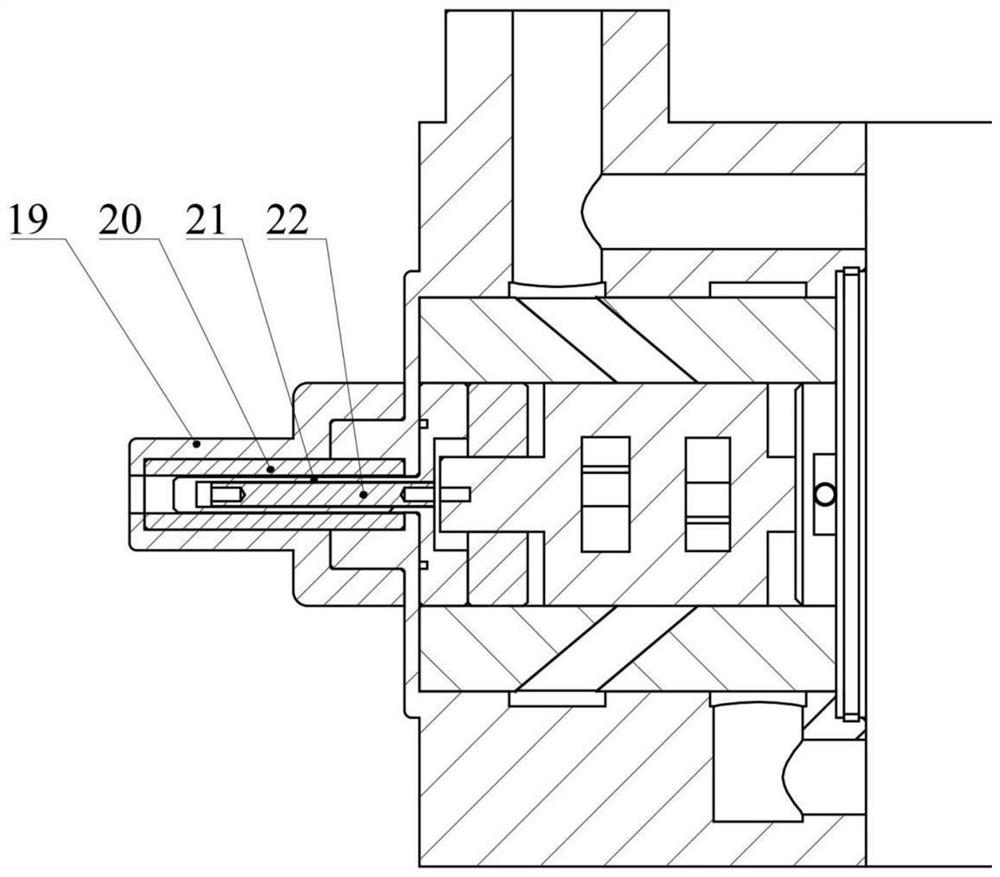

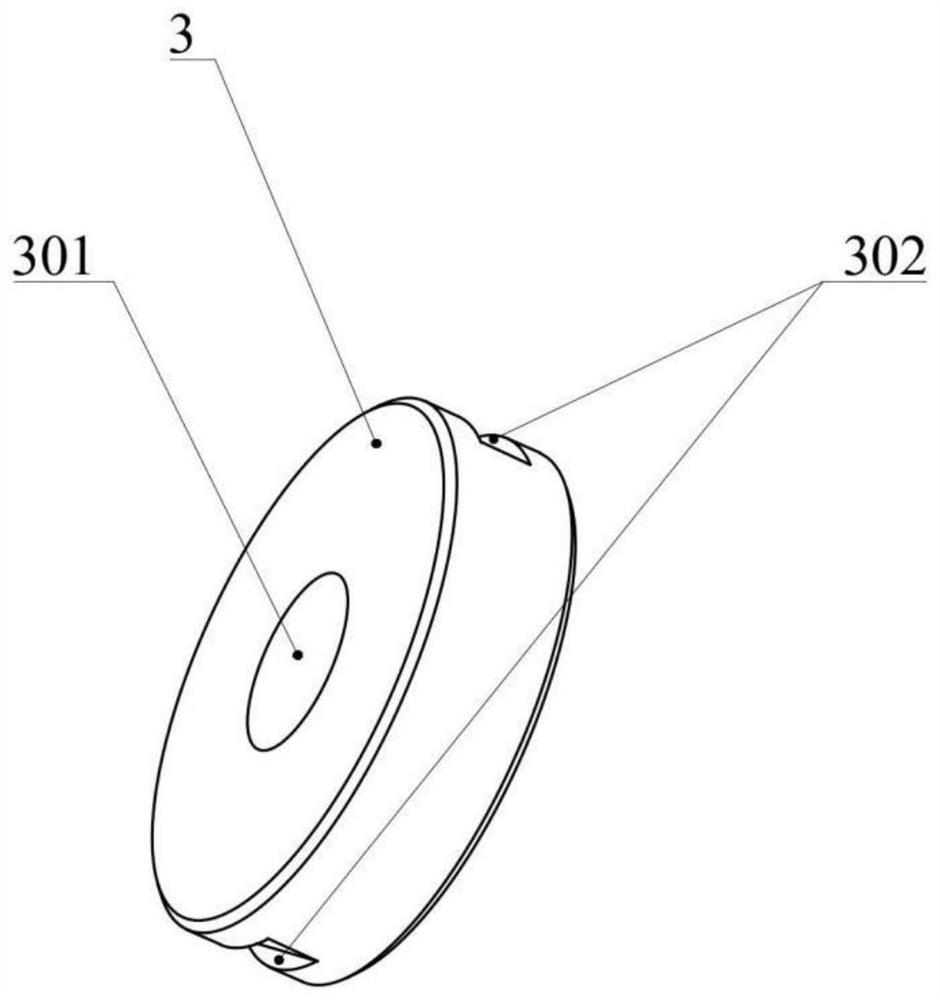

[0092] Embodiments of the present application by providing a stack of two-dimensional double rolling piston type flowmeter dynamic, lag solve technical problems in the prior art read volumetric flowmeter dynamic flow exists.

[0093] Technical solutions in the embodiments of the present application to solve the above problems, the general idea is as follows: in the embodiment of the present application by the left piston 5 connected to the left end of the left of the piston 5 for detecting the axial velocity of the left velocity sensor assembly 1, in the right end of the right piston 17 connected to the right of the piston 17 for detecting the axial velocity component of the right velocity sensor 18; the left velocity sensor assembly 1 and the right velocity sensor assembly 18 are connected to the central processor, the central processor receives the left velocity signal and right velocity signal of the left velocity sensor assembly 1 and the emitted right velocity sensor assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com