A package dynamic weighing device and its weighing method

A dynamic weighing and wrapping technology, applied in the field of weighing, can solve the problems of low conveying efficiency, low weighing efficiency, and long weighing time of a single package, and achieve the effects of improving transportation efficiency, reducing the minimum distance, and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

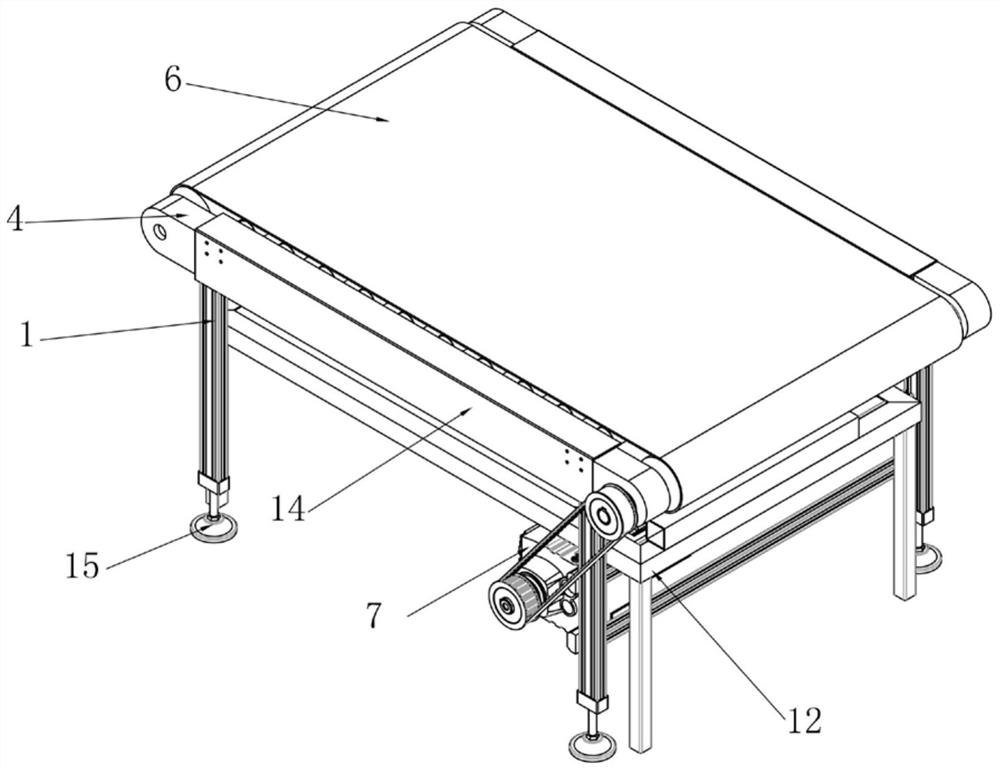

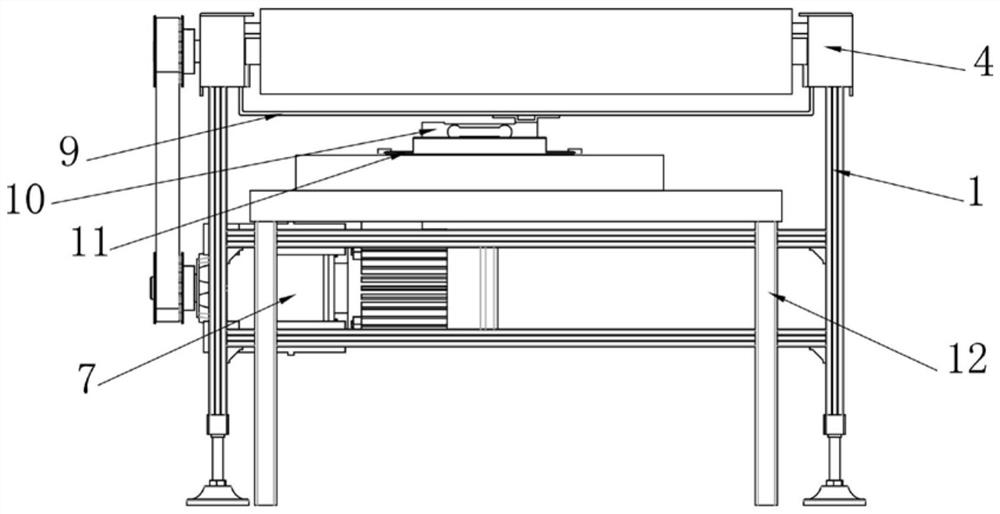

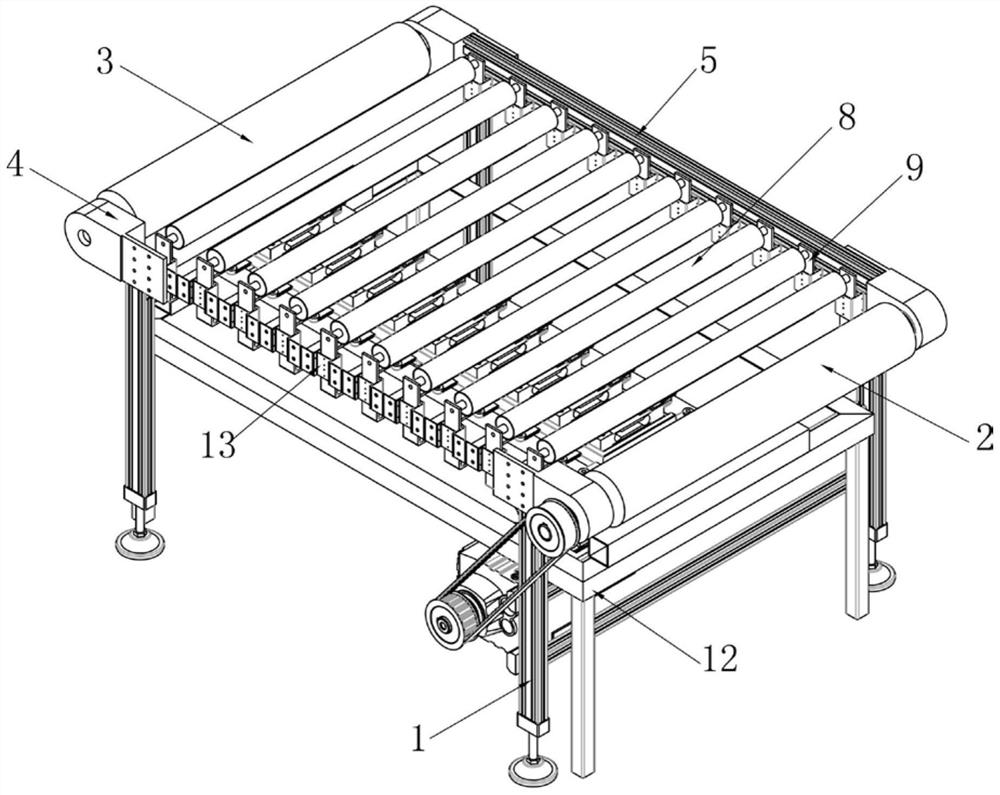

[0025] Such as Figure 1 to Figure 4 As shown, the package dynamic weighing equipment described in this embodiment includes a frame 1, a driving roller 2, a driven roller 3, a roller fixing seat 4, an aluminum profile 5, a conveyor belt 6, a driving motor 7, and a weighing idler roller 8 , U-shaped idler support frame 9, load cell 10, sensor bracket 11, weighing platform 12 and limit device 13; the driving drum 2 and the driven drum 3 are respectively mounted on the frame through two drum fixing seats 4 1; and an aluminum profile 5 is installed between the two roller fixing seats 4 on the same side of the frame 1, and the outer side between the two roller fixing seats 4, that is, the outer side of the aluminum profile 5 is equipped with a protective The cover 14 prevents the internal parts from being affected by dust; a conveyor belt 6 is arranged between the driving roller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com