Probe holding structure

A technology of probes and electrode substrates, which is applied to the parts, instruments, and measuring devices of electrical measuring instruments, which can solve the problems of increased maintenance costs and complicated replacement operations, and achieve the effect of improving position accuracy and reducing the minimum spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

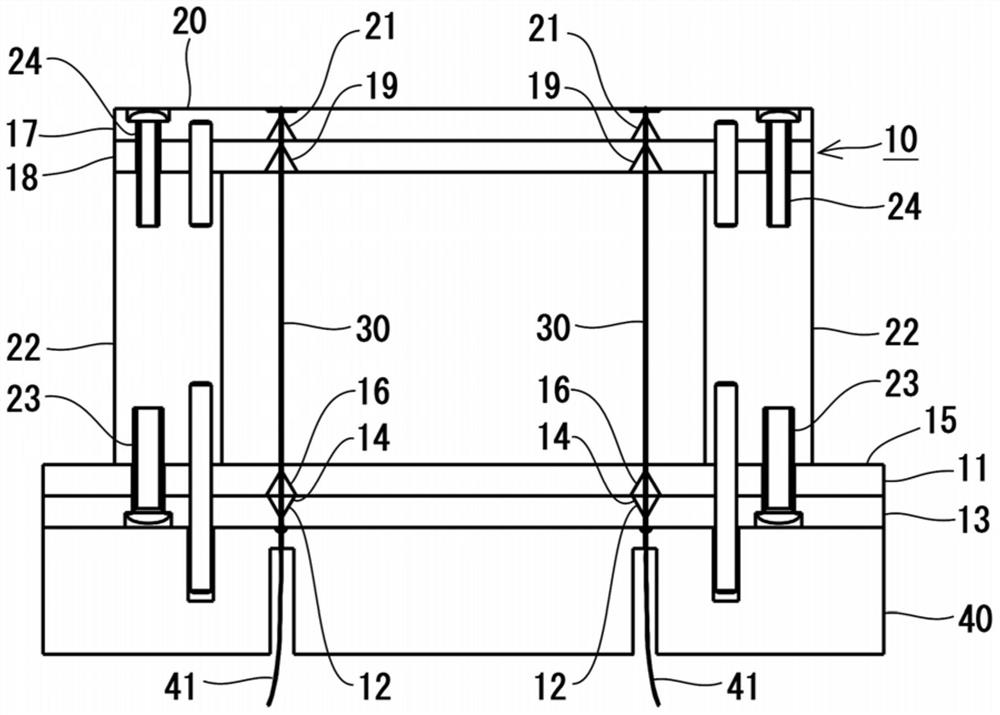

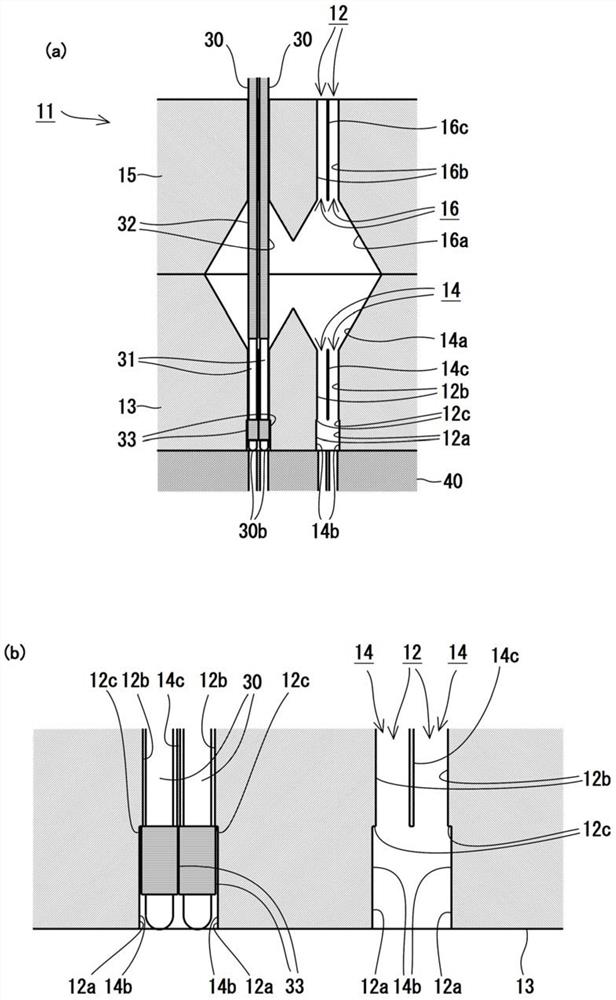

[0031] Embodiments of the present invention will be described with reference to the drawings.

[0032] The holding structure of the probe 30 in this embodiment includes the probe 30 and the probe jig 10 that holds both ends of the probe 30 and is arranged between the electrode substrate 40 and the substrate to be inspected (not shown).

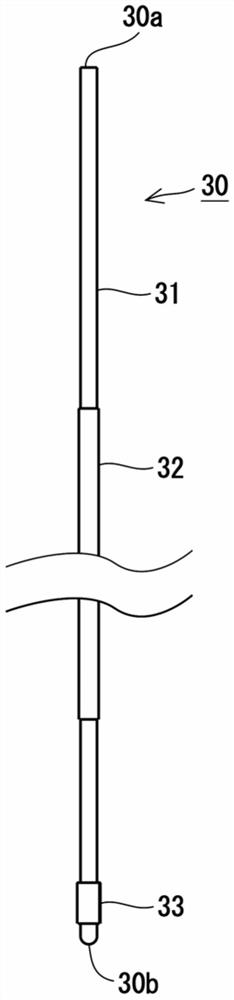

[0033] Such as figure 2 , etc., the probe 30 is a member having an insulating coating 32 and a locking portion 33 on the outer peripheral portion of a conductive metal pin 31 . The insulating coating 32 is an insulating coating covering the outer periphery of the metal pin 31 at the middle portion of the probe 30 . By providing the insulating coating 32 , even when the probe 30 is bent, insulation from other probes 30 is ensured. In addition, the locking portion 33 is an annular insulator attached to the outer periphery of the metal pin 31 in the vicinity of the rear end portion 30 b of the probe 30 . The locking portion 33 ensures the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com