Point switch fault detection device based on acoustics

A fault detection and switch machine technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inaccurate classification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]For the aforementioned and other technical content, characteristics and efficacy of the present invention, with reference to referenceFigure 1-3In the detailed description of the embodiments, it will be clearly presented. The structural content mentioned in the following examples is referenced in the accompanying drawings.

[0023]Each of the exemplary embodiments of the present invention will be described below with reference to the drawings.

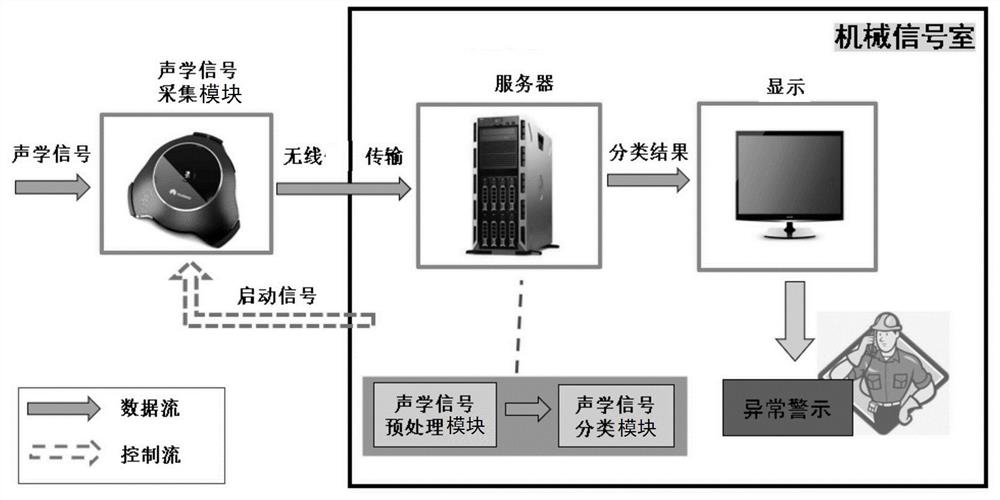

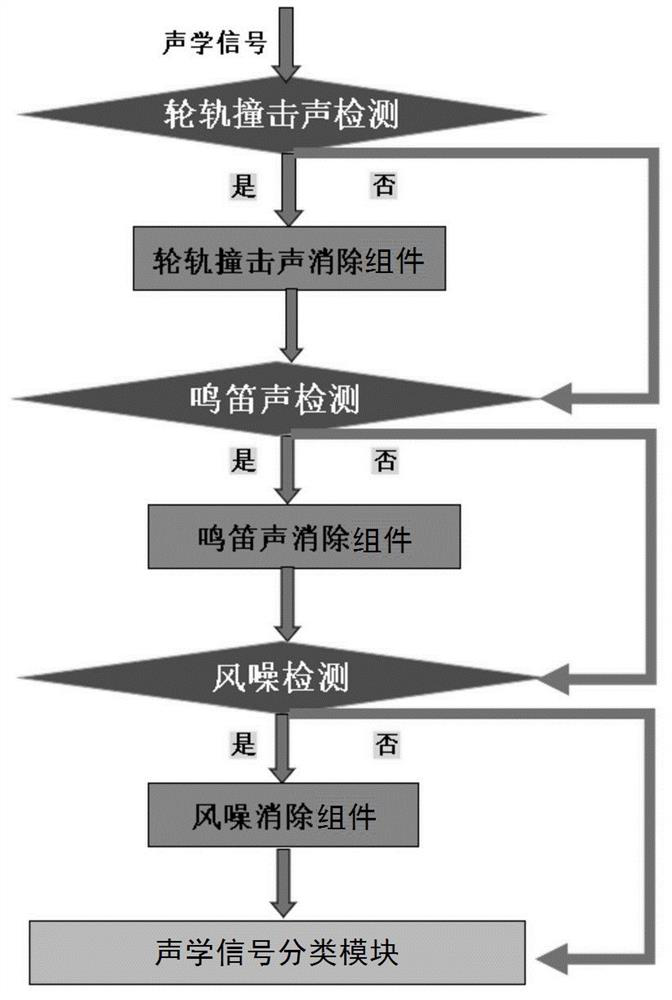

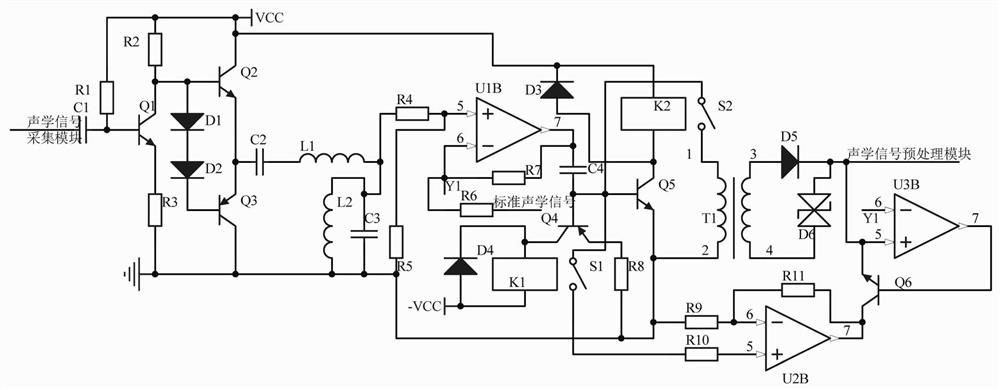

[0024]An acoustic-based turning machine fault detection device including an acoustic signal acquisition module, an acoustic signal preprocessing module, an acoustic signal classification module, and the acoustic signal acquisition module is applied to the air near the target switching machine, The acoustic signal preprocessing module and an acoustic signal classification module uses on a server within the mechanical signal in the station, and the mechanical signal chamber starts the acoustic signal acquisition module by the start signal. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com