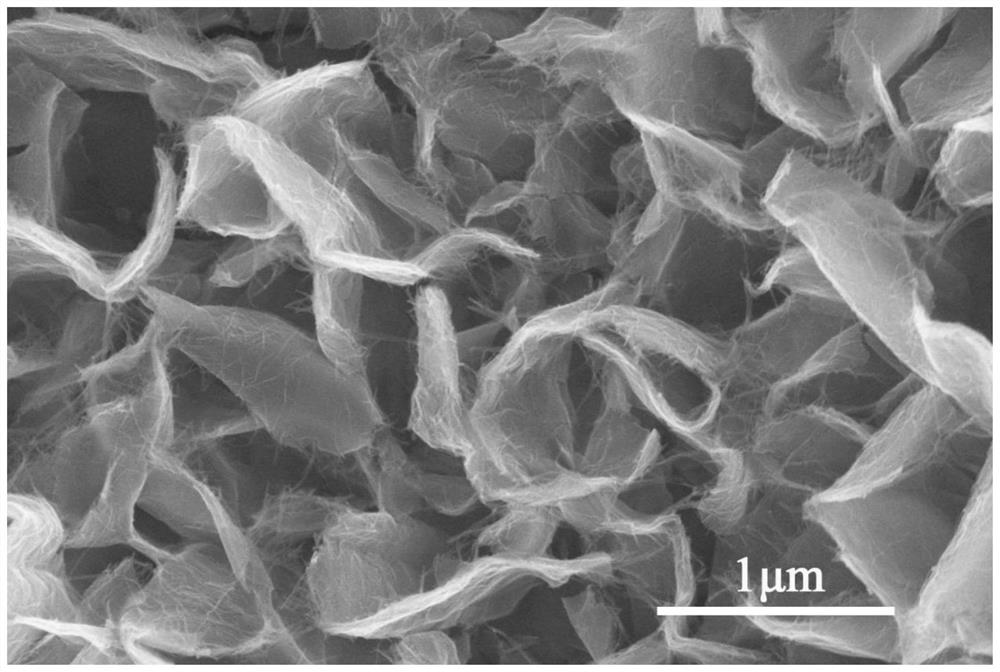

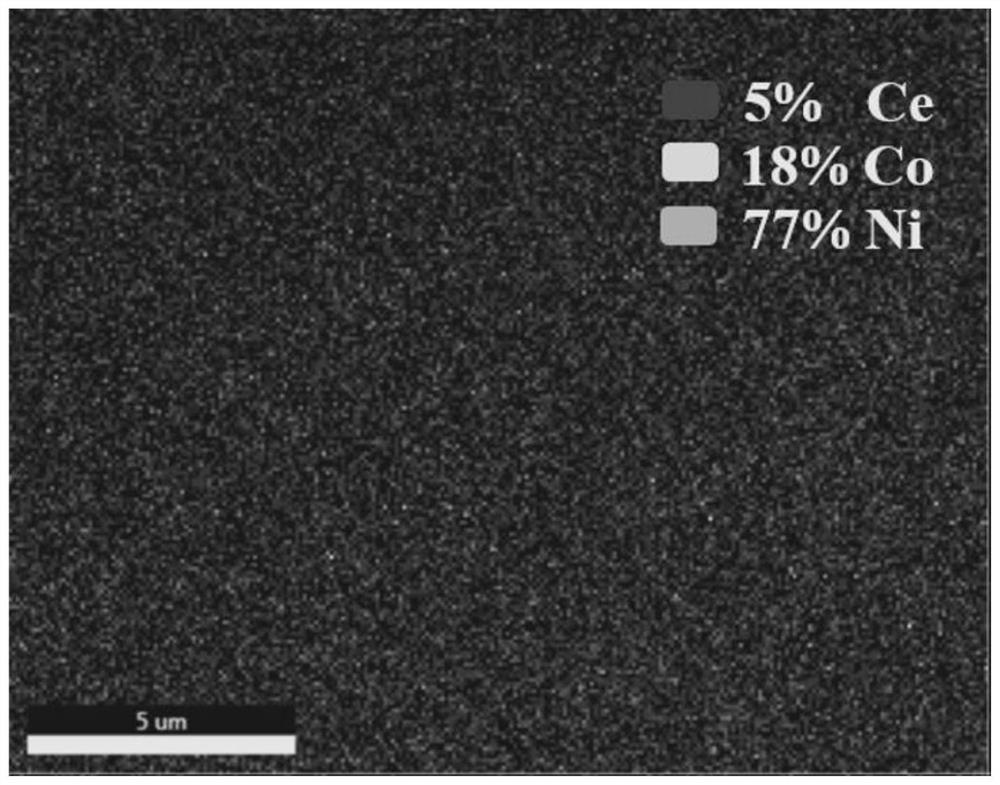

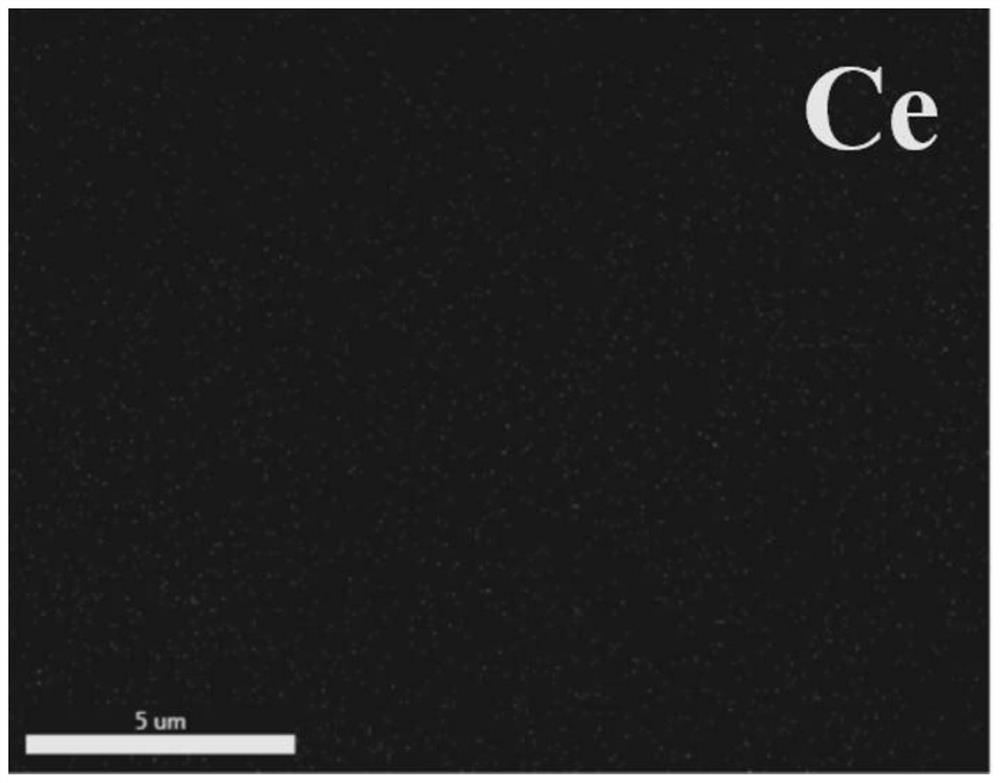

A kind of flaky ceo2/co1.29ni1.71o4 electrode material and its preparation method

A co1.29ni1.71o4, electrode material technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor conductivity and cycle stability, affecting the performance of supercapacitors, etc., to alleviate poor conductivity and The effects of poor cycle stability, low requirements for synthesis conditions, and simple operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Cut 30mm×10mm×1.5mm nickel foam with a pore size of 110ppi, soak it in 2M HCL and ultrasonically clean it for 15 minutes, then ultrasonically clean it with deionized water for 10 minutes, and finally use anhydrous ethanol for 10 minutes, and vacuum-dry the nickel foam after ultrasonication at 60°C for 12 hours.

[0028] Weigh 0.050g sodium lauryl sulfate, 0.050g urea, 0.116g nickel nitrate hexahydrate and 0.116 g cobalt nitrate hexahydrate and dissolve in 20mL deionized water, stir for 20min to obtain the initial solution; weigh 0.012g cerium nitrate hexahydrate to dissolve In 10 mL of deionized water, an aqueous cerium nitrate solution with a concentration of 2.76 mmol / L was obtained; the aqueous cerium nitrate solution was slowly added dropwise to the initial solution under stirring, and the stirring was continued for 1 h to obtain a uniform solution.

[0029] Move the dried nickel foam and homogeneous solution into the reactor, react at 170°C for 12h, wash the reacted...

Embodiment 2

[0035]Cut 30mm×10mm×1.5mm nickel foam with a pore size of 110ppi, soak it in 1M HCL and ultrasonically clean it for 10 minutes, then sonicate it with deionized water for 10 minutes, and finally use anhydrous ethanol for 10 minutes, and dry the nickel foam after ultrasonication at 60°C for 12 hours in vacuum.

[0036] Weigh 0.055g sodium lauryl sulfate, 0.050g urea, 0.185g nickel nitrate hexahydrate and 0.185g cobalt nitrate hexahydrate and dissolve in 20mL deionized water, stir for 20min to obtain the initial solution; weigh 0.008g cerium nitrate hexahydrate to dissolve In 10 mL of deionized water, an aqueous solution of cerium nitrate with a concentration of 1.84 mmol / L was obtained; the aqueous solution of cerium nitrate was slowly added dropwise to the initial solution under stirring, and the stirring was continued for 1 h to obtain a uniform solution.

[0037] Move the dried nickel foam and homogeneous solution into the reaction kettle to react at 170°C for 11 hours, wash t...

Embodiment 3

[0039] Cut 30mm×10mm×1.5mm nickel foam with a pore size of 110ppi, soak it in 2M HCL and ultrasonically clean it for 15 minutes, then ultrasonically clean it with deionized water for 10 minutes, and finally use anhydrous ethanol for 10 minutes, and vacuum-dry the nickel foam after ultrasonication at 60°C for 12 hours.

[0040] Weigh 0.050g sodium lauryl sulfate, 0.055g urea, 0.245g nickel nitrate hexahydrate and 0.245g cobalt nitrate hexahydrate and dissolve in 20mL deionized water, stir for 20min to obtain the initial solution; weigh 0.016g cerium nitrate hexahydrate and dissolve In 10mL of deionized water, obtain a cerium nitrate aqueous solution with a concentration of 3.68mmol / L; slowly add a cerium nitrate aqueous solution to the initial solution under stirring, continue stirring for 1.5h to obtain a uniform solution, and transfer the dried nickel foam and the uniform solution into the reaction React in the kettle at 180°C for 12h, wash the reacted nickel foam with water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com