Mounting device for back-to-back double zipper pullers

An installation device and double zipper technology, which is applied in the field of garment processing, can solve problems such as low production efficiency, long assembly process, and manual installation cannot be completed, so as to reduce production costs, improve economic benefits, and improve work efficiency and production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

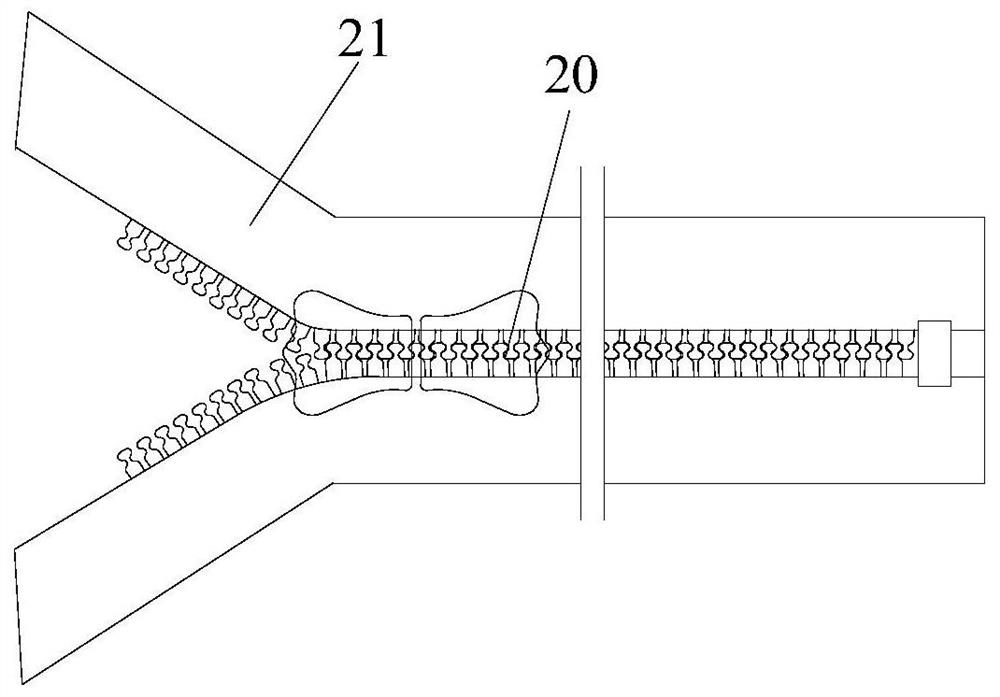

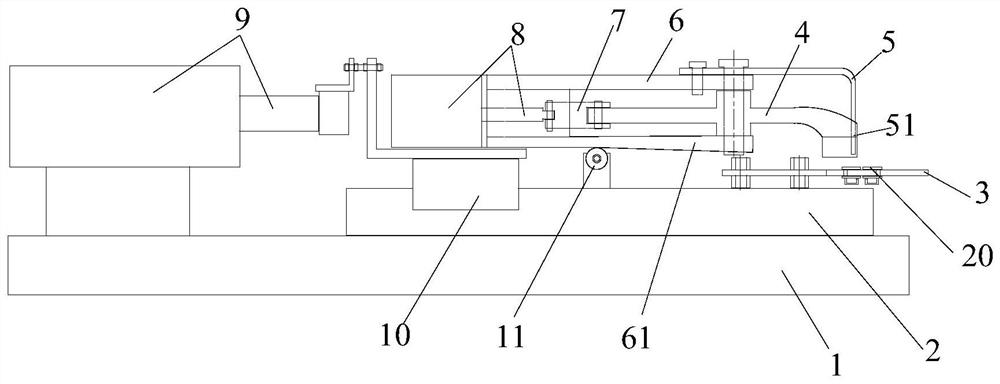

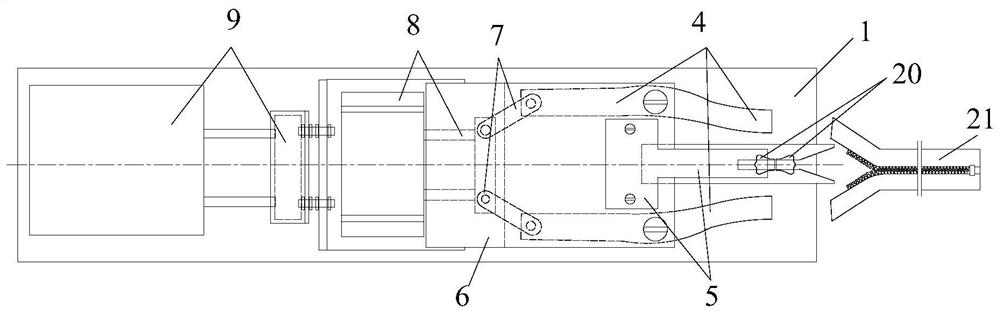

[0025] Figure 2 ~ Figure 4 Some embodiments according to the invention are shown.

[0026] Such as Figure 2~4 As shown, a back-to-back installation device for double zipper pulls includes: a base 1, a sliding guide rail 2, a slider 10, a mounting bracket 6 installed on the slider 10, a linear cylinder-8, and a rear end of the linear cylinder-8. Linear cylinder two 9, movable clamp 4 and L-shaped baffle plate 5 that the front end of mounting bracket 6 is provided with, and the installation guide plate 3 that movable clamp 4 undersides are provided with.

[0027] Specifically, such as figure 2 As shown, the base 1 is fixed on the workbench as the base of the whole device, and the sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com