Amorphous metal encapsulation forming device and process

An amorphous metal and forming device technology, which is applied in the field of amorphous metal overmolding forming device and forming process, can solve the problems of long time for placing workpieces, low work efficiency, prolonging production cycle, etc., so as to shorten the production cycle and improve the work. The effect of efficiency and productivity benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

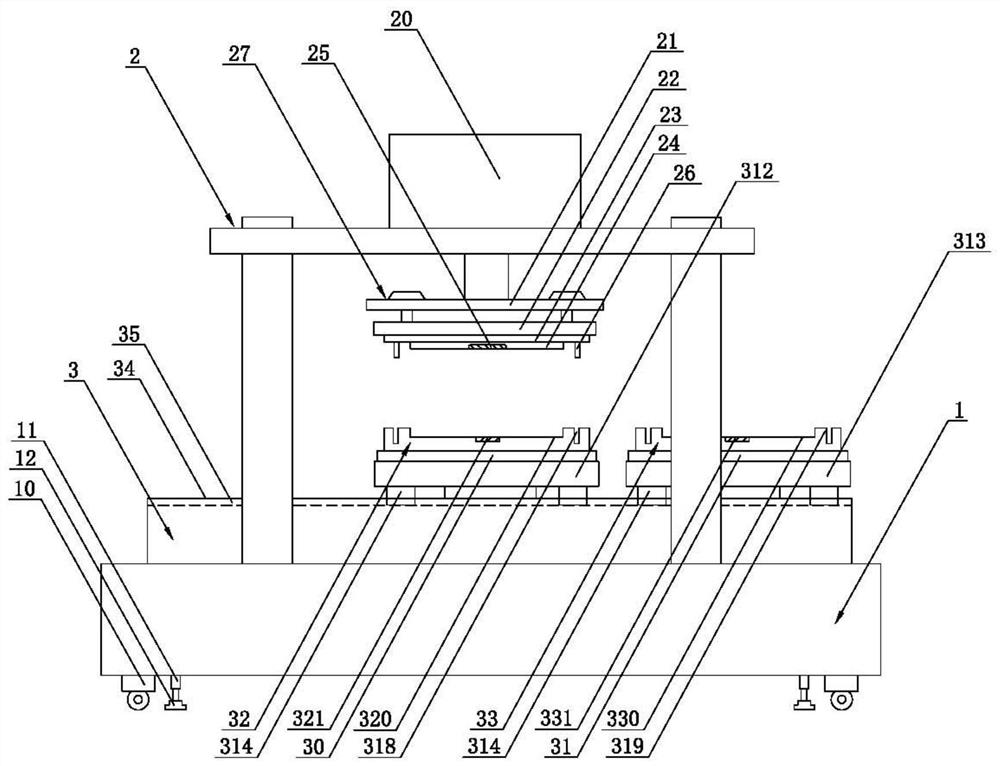

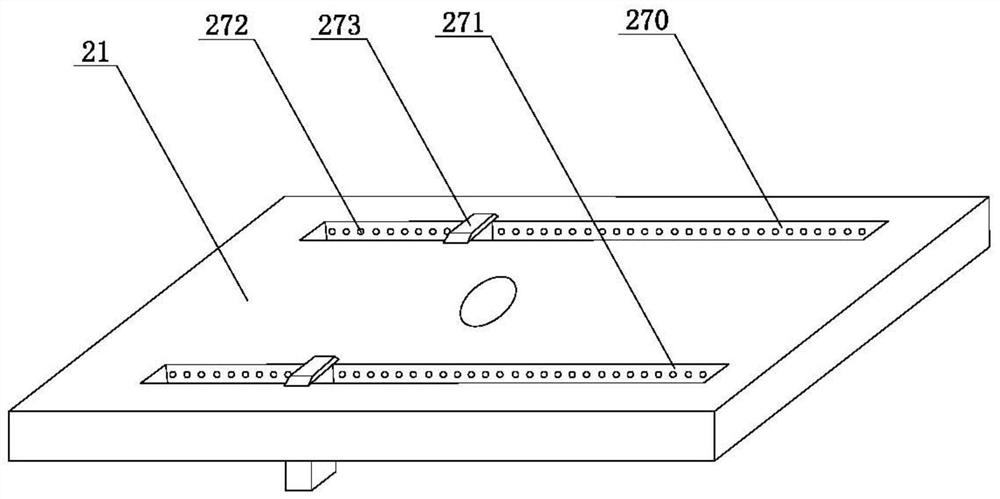

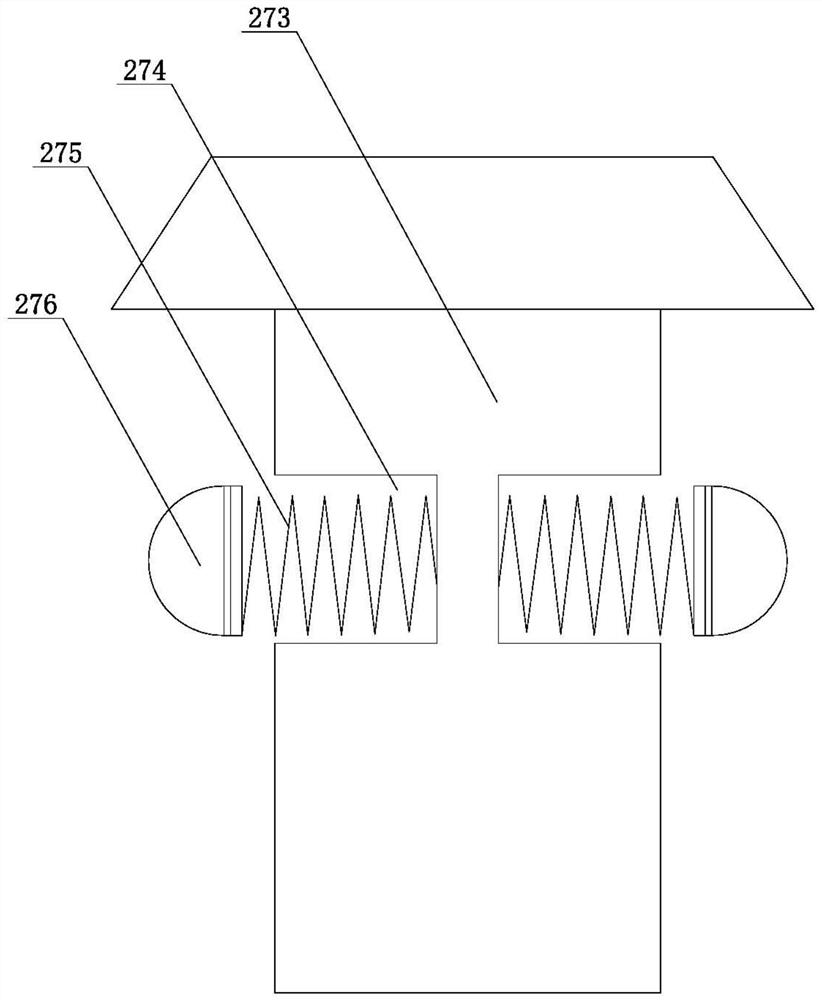

[0041] Such as Figure 1 to Figure 5 As shown, an amorphous metal overmolding device of the present invention includes a machine platform 1, a support frame 2 vertically arranged on the top of the machine platform 1, and the support frame 2 is provided with a driving member 20, and the driving member 20 The output end passes through the support frame 2 and is connected with a moving plate 21. The moving plate 21 is provided with an upper mold heating element 22 and an upper mold 23 connected with the upper mold heating element 22. The support frame 2 is provided with a The feeding mechanism 3, the output end of the feeding mechanism 3 is driven and connected with the first lower mold heating element 30 and the second lower mold heating element 31, and the first lower mold heating element 30 and the second lower mold heating element 31 are respectively A first lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com