A kind of limestone powder making process

A limestone and process technology, which is applied in the field of limestone pulverizing technology, can solve the problems of reducing the production efficiency of limestone pulverizing, the process is complicated, and the area is large, so as to achieve the best crushing effect, simplify the process and save the floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

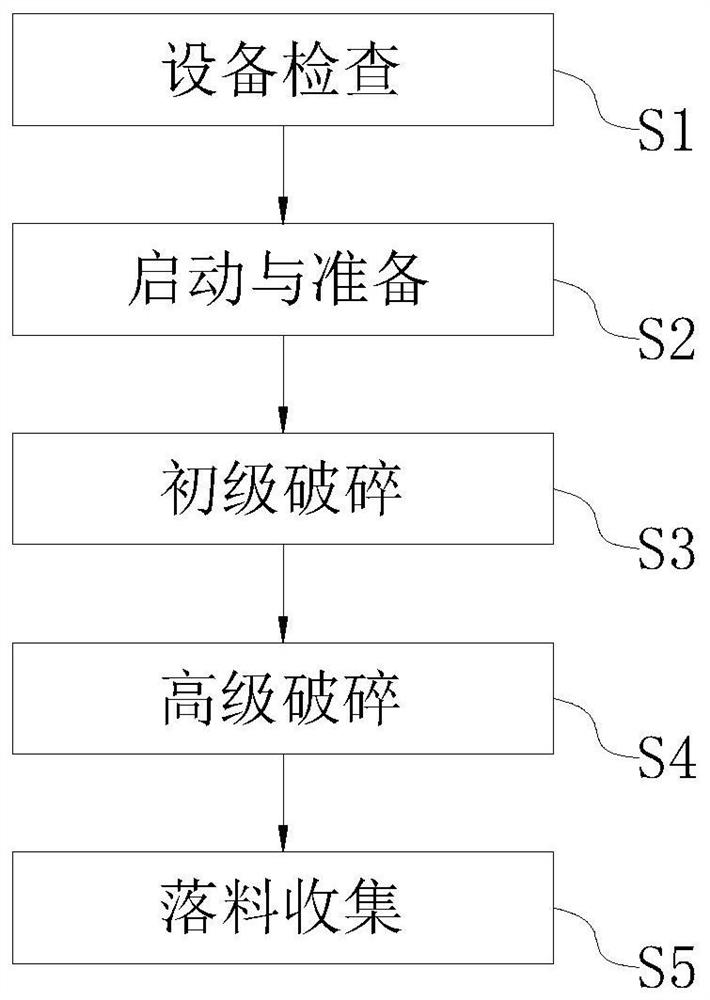

[0037] The following is attached Figure 1-8 The present invention is described in further detail.

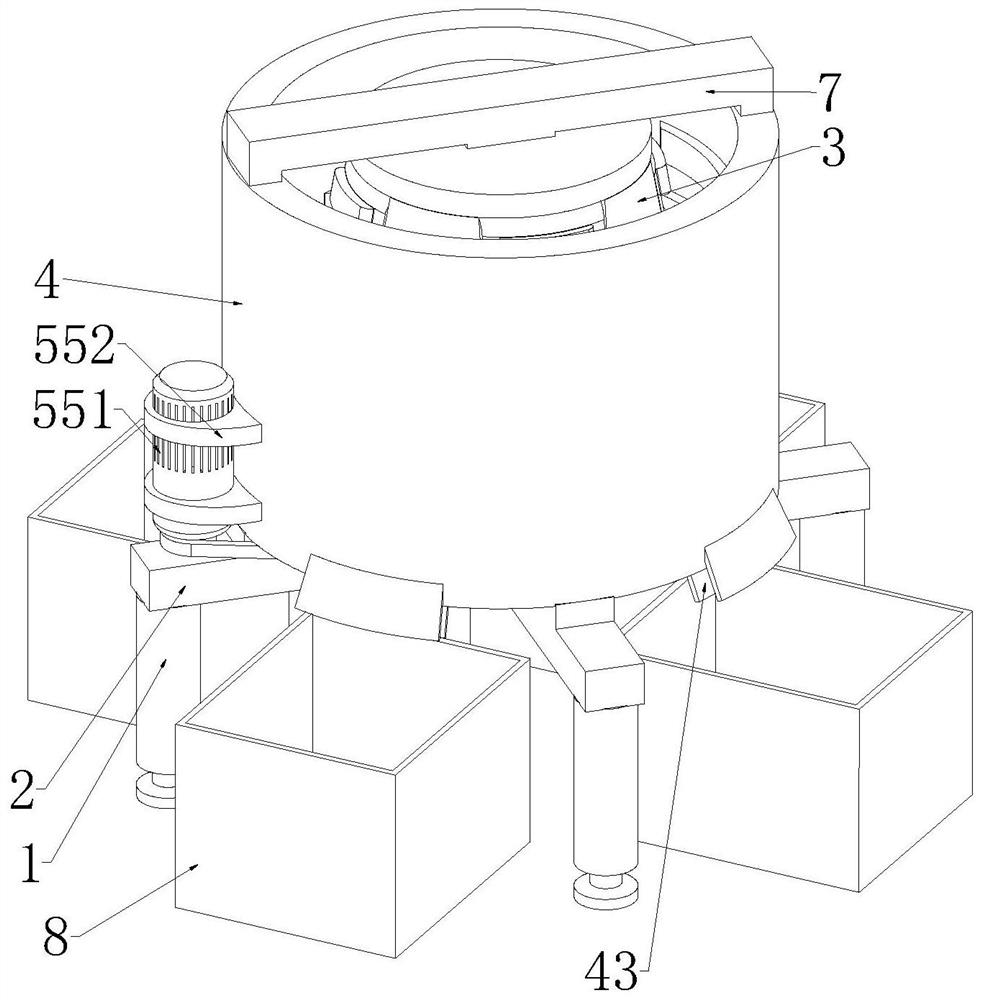

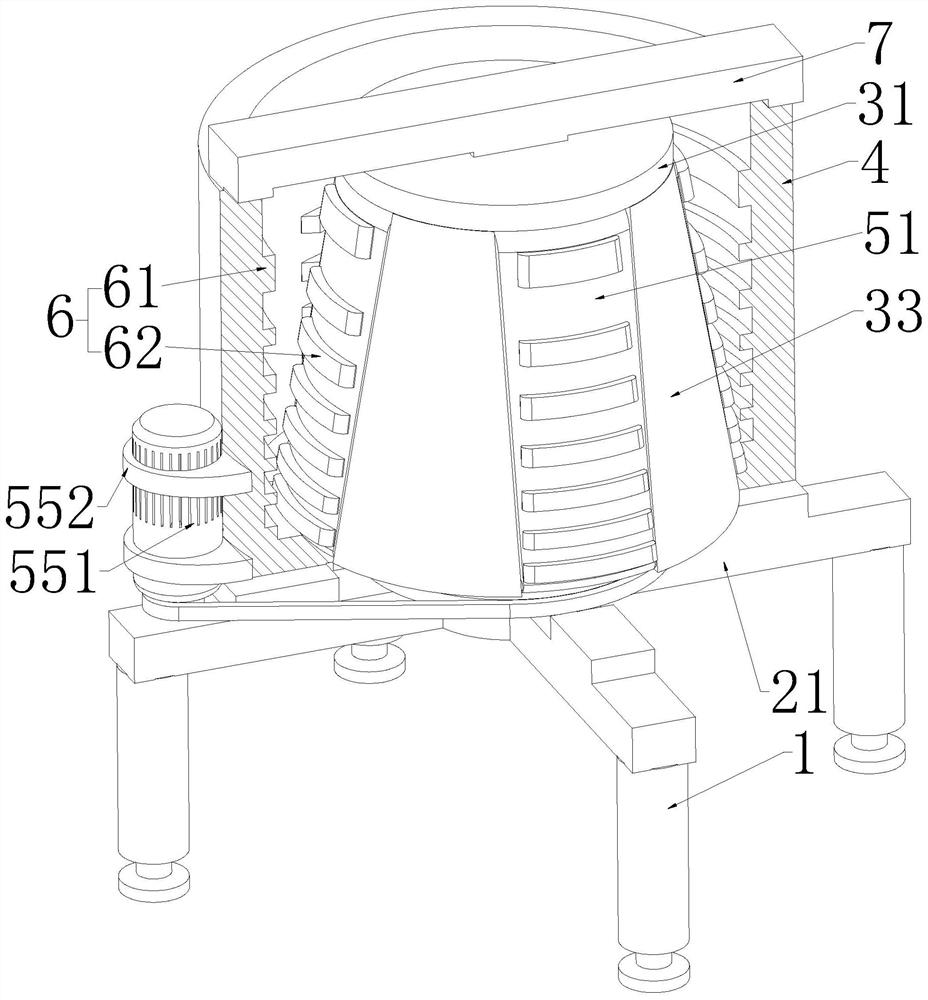

[0038] A limestone powder-making process, which uses a limestone powder-making equipment, the equipment includes a support frame 1, a workbench 2, a fixed jaw plate 3, a fixed cylinder 4, a rotating extrusion device 5, an engaging device 6 and a connecting block 7 , several support frames 1 are evenly arranged on the ground, the worktable 2 is provided at one end of several support frames 1 away from the ground, the fixed cylinder 4 is provided on the workbench 2, and the connecting block 7 is provided on the fixed cylinder 4 One end away from the ground, the end of the fixed jaw plate 3 close to the ground is pierced through the fixed cylinder 4 and connected to the workbench 2 in rotation, the end of the fixed jaw plate 3 away from the ground is connected to the connecting block 7 in rotation, and the bottom of the fixed jaw plate 3 The rotation is installed on the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com