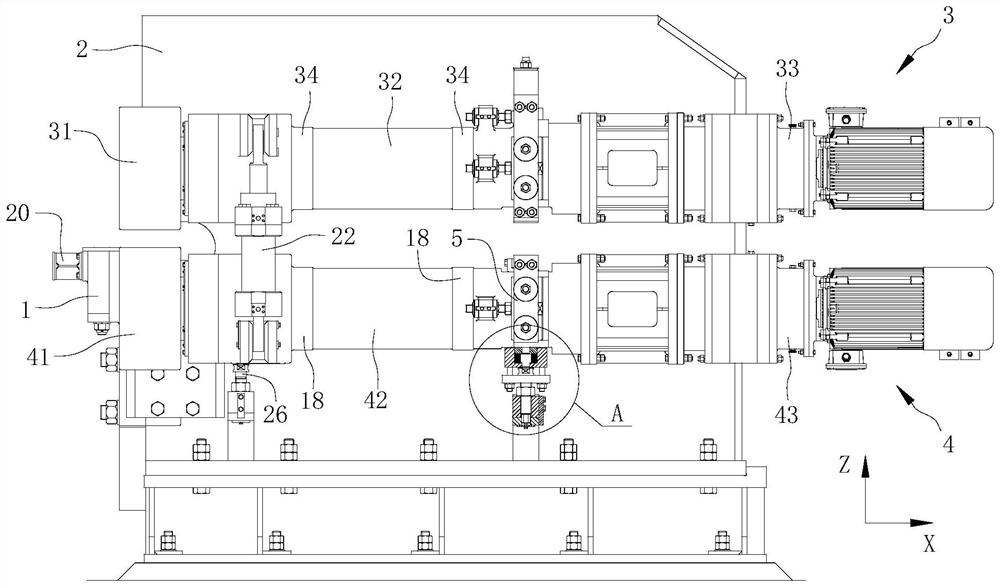

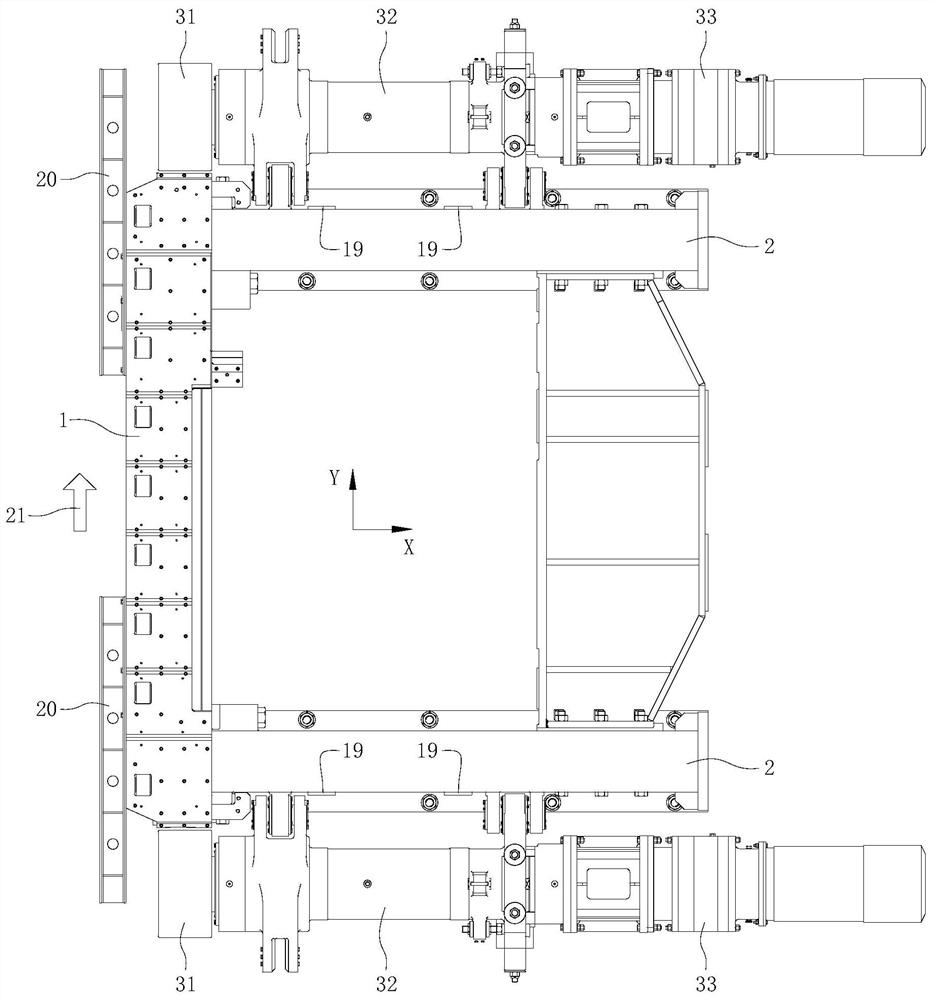

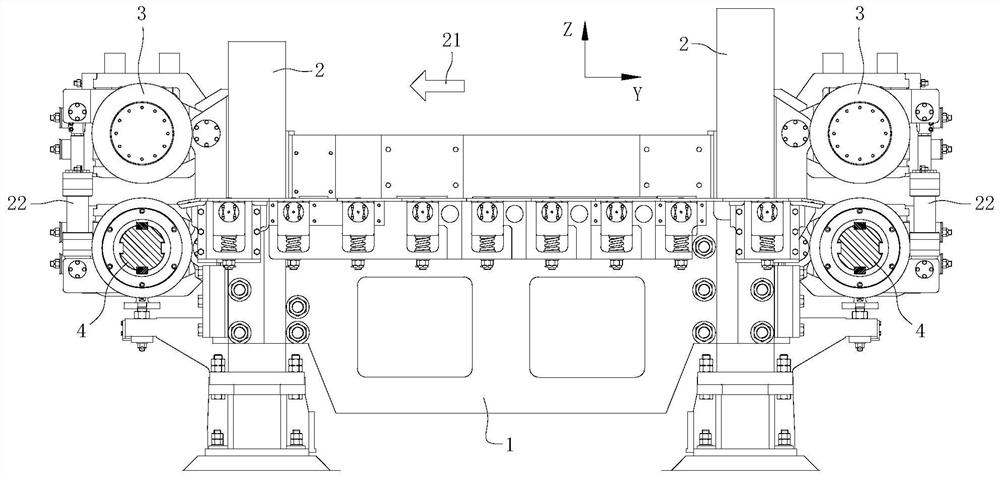

Pinch roller device

A pinch roll and roll body technology, applied in the field of shearing equipment, can solve the problems of steel plate deviation, steel plate misalignment, and reduce the quality of steel plate shearing, and achieve the effect of increasing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] As an embodiment, the elastic device is a compression spring 14 , the upper end of the compression spring 14 abuts against the bottom of the lower pinch roller body 42 , and the lower end of the compression spring 14 abuts against the bottom of the installation hole 12 . As another embodiment, the elastic device includes a top plate 13 abutting against the bottom of the lower pinch roller body 42 , and a compression spring 14 arranged under the top plate 13 . The top plate 13 can move up and down in the installation hole 12 , and under the action of the compression spring 14 , the top plate 13 abuts and cooperates with the bottom of the lower pinch roller body 42 . By setting the top plate 13 , the pressure of the compression spring 14 on the bottom of the lower pinch roller body 42 can be dispersed to prevent the bottom of the lower pinch roller body 42 from being scratched by the compression spring 14 . Preferably, the bottom of the top plate 13 has a guide rod 15 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com