A network cable positioning system for smart factory Internet

An Internet and line positioning technology, which is applied in thin material processing, delivery of filamentous materials, transportation and packaging, etc., can solve problems such as high cost, error-prone, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

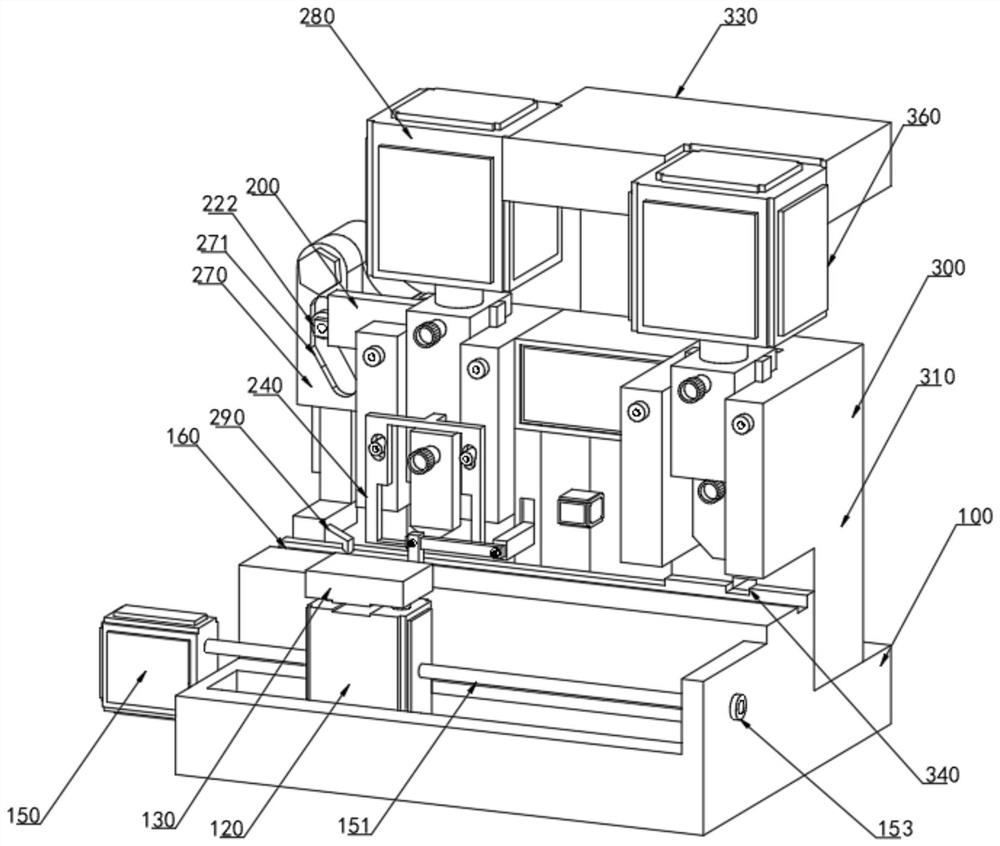

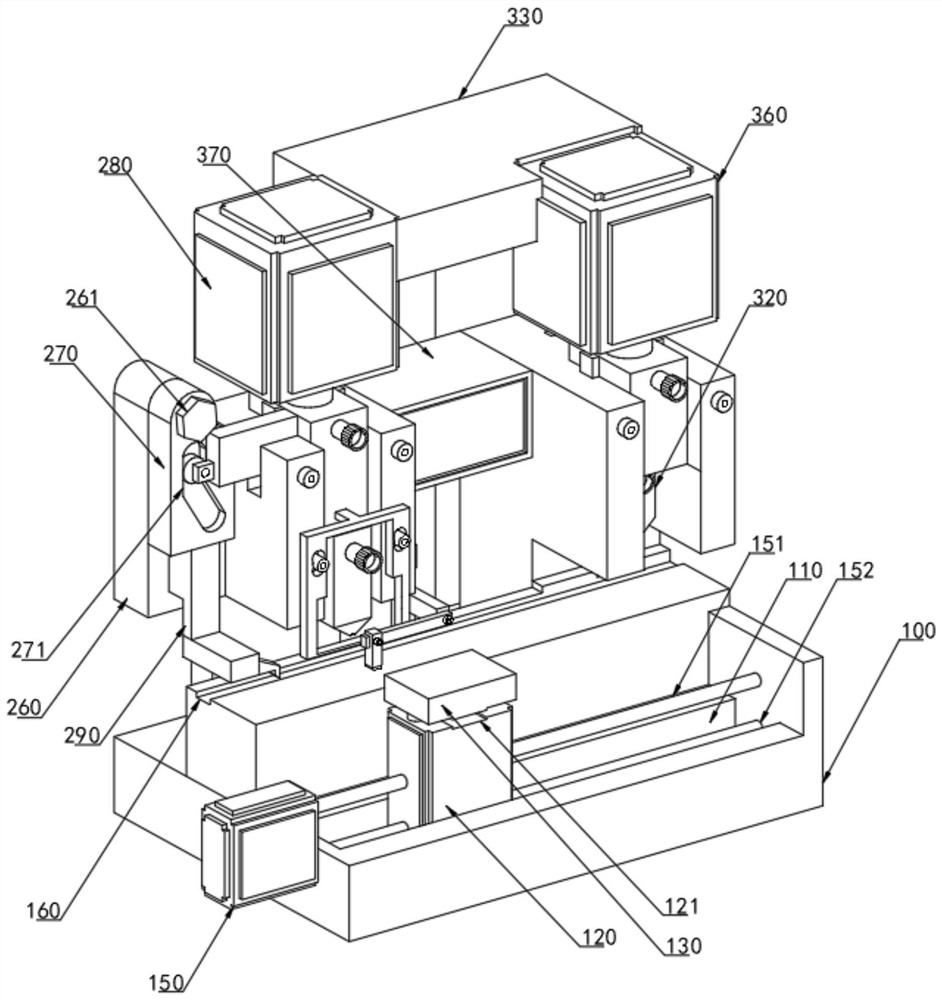

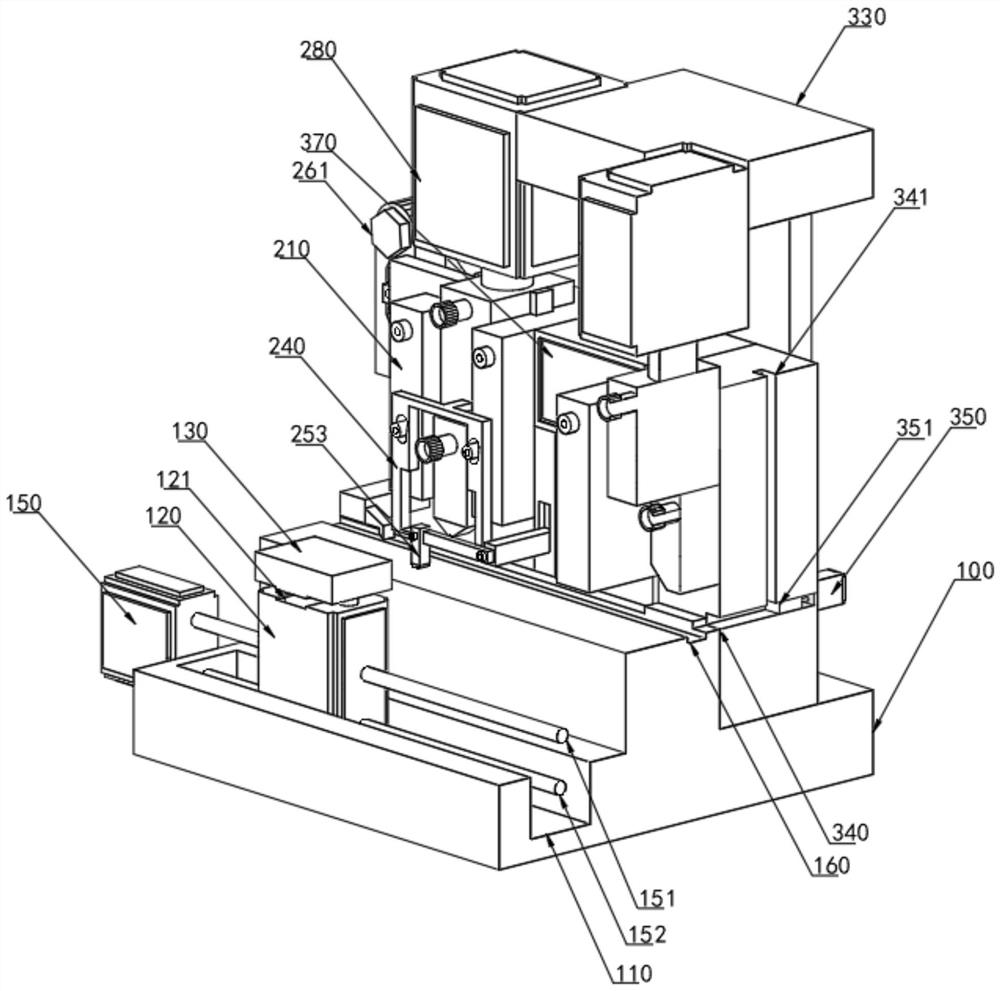

Image

Examples

Embodiment 2

[0050] Refer to the attached Figure 13 , a smart factory Internet network cable positioning system for this embodiment also includes a bottom button 2 390;

[0051] Further, the inner wall of the line trough 160 is evenly provided with a bottom buckle 2 390, and the top of the bottom buckle 390 is fixedly equipped with a baffle plate 2 391. , specifically, the wire transport trough 160 has the function of limiting and transporting the bottom buckle 2 390, the bottom buckle 2 390 has the function of fixing and supporting the baffle 2 391, and the gaps between the five sets of baffles 2 391 have the function of installing four sets of core network cables. The ratchet 290 has the function of moving the baffle plate 2 391 for intermittent movement, and the two sides of the bottom buckle 390 are extended to ensure that the gap between the baffle plate 2 391 is equal when multiple groups of bottom buckle 2 390 are combined, so that the pawl 290 can be moved. Baffle plate two 391 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com