A fully automatic assembly conveyor line for power distribution cabinets

A fully automatic, conveying line technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as inability to perform fully automatic assembly work, and achieve the effects of stable work, reduced production costs, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

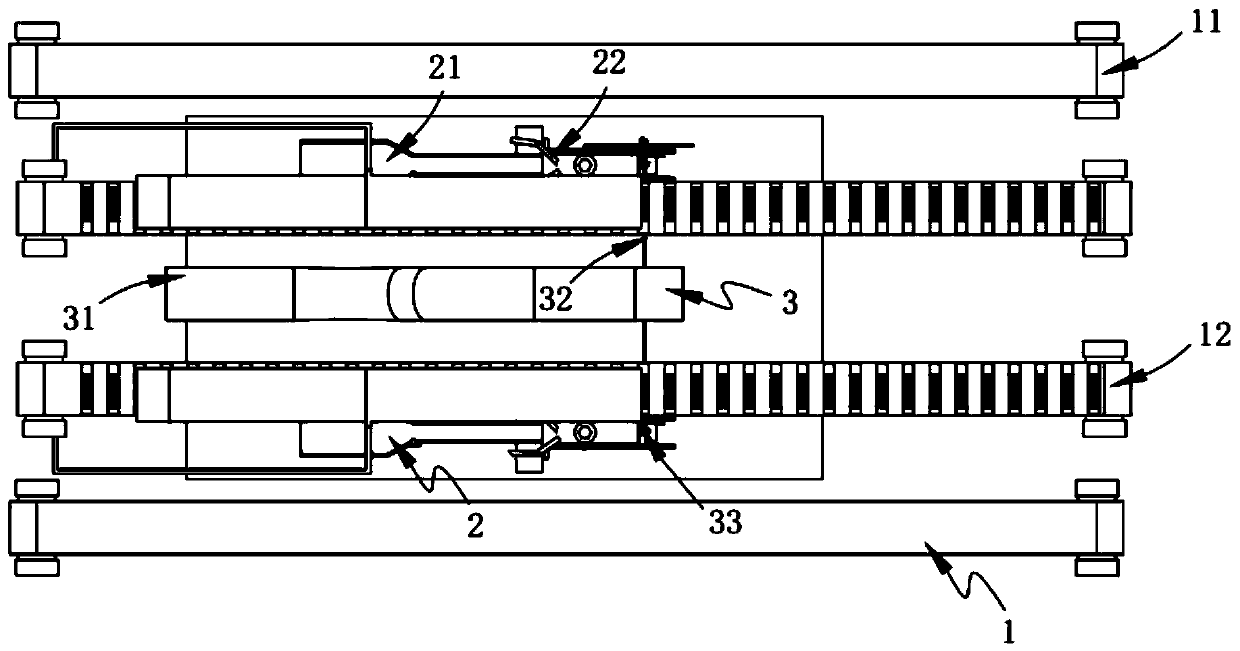

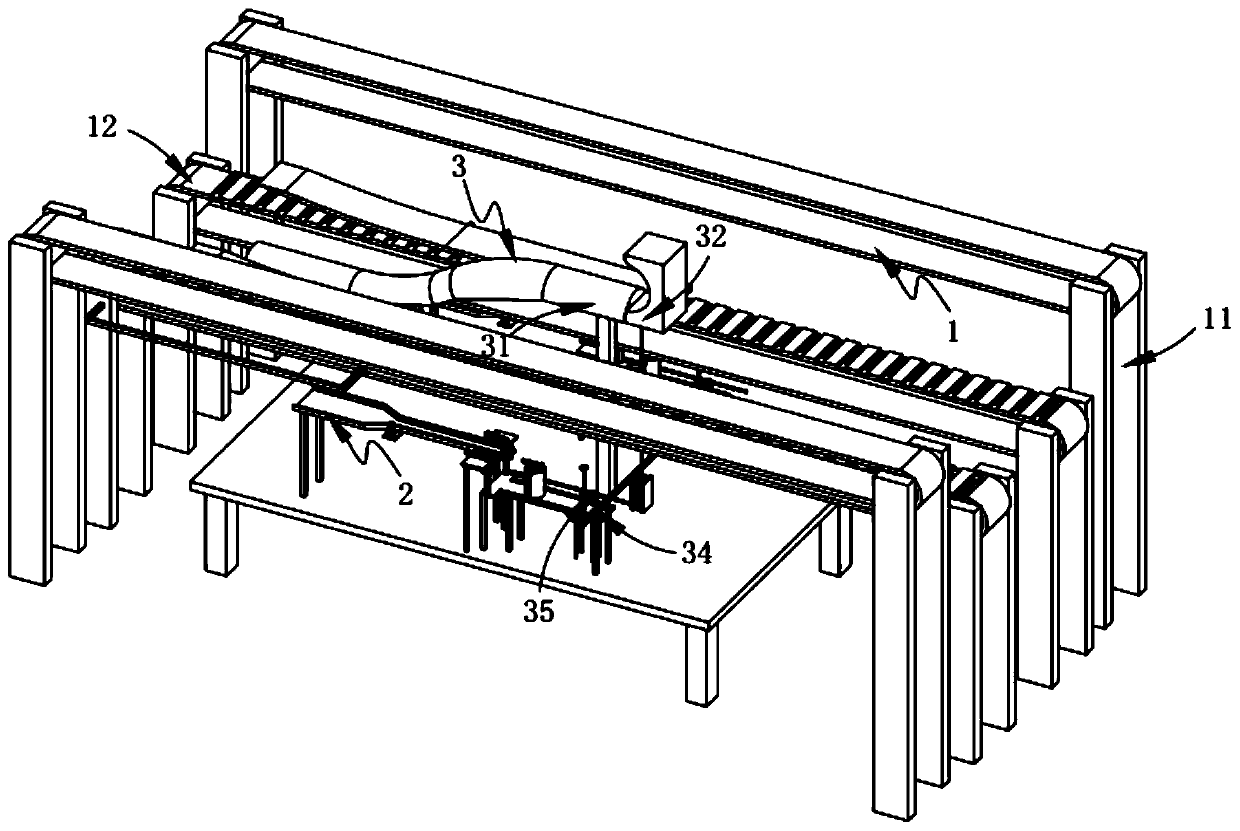

[0064] Such as figure 1 , figure 2 As shown, a fully automatic assembly conveyor line for power distribution cabinets includes:

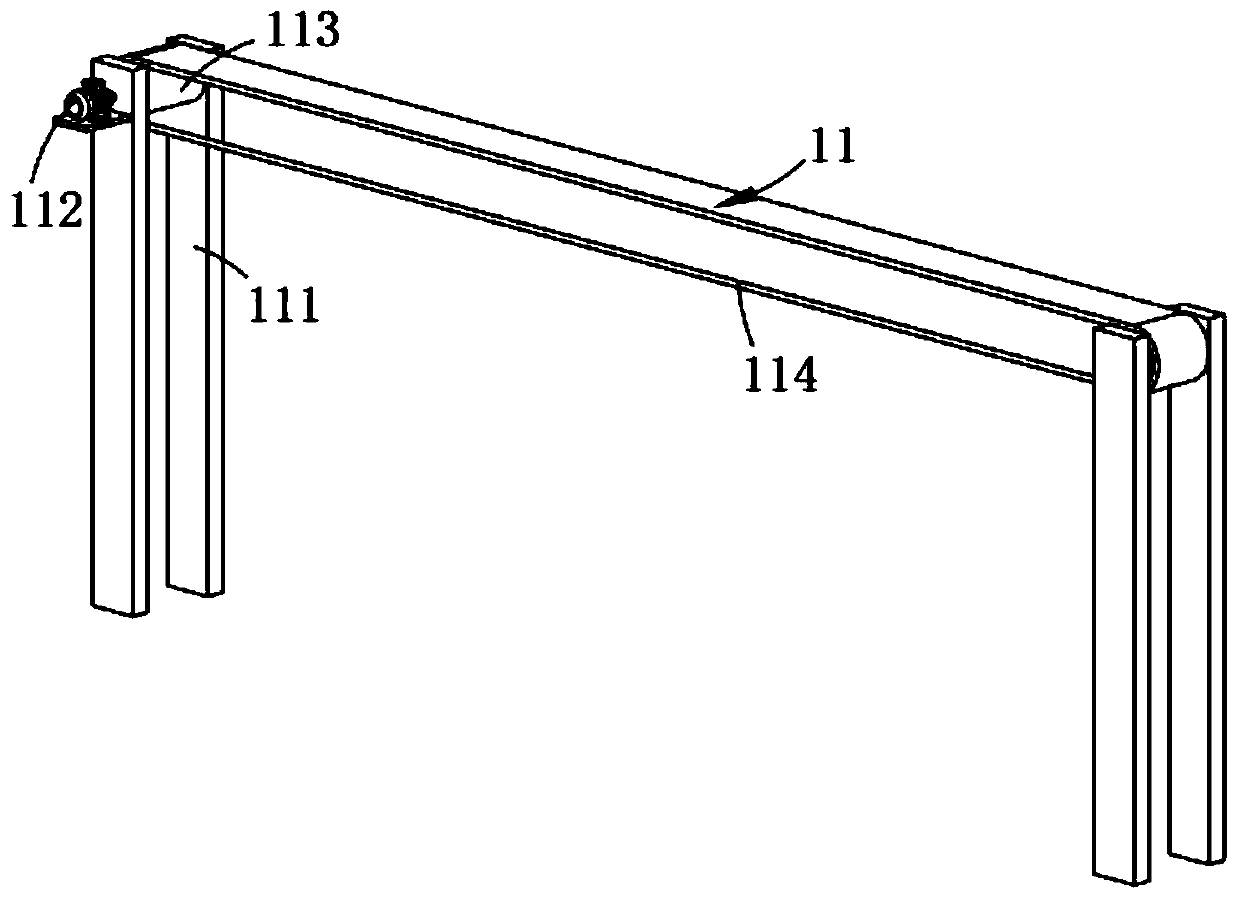

[0065] A raw material transfer mechanism 1, the raw material transfer mechanism 1 includes a workpiece feeding assembly 11 arranged symmetrically and a zero-line feeding assembly 12 arranged along the width direction of the workpiece feeding assembly 11 and symmetrically arranged on both sides of the workpiece feeding assembly 11 ;

[0066] Nut transmission mechanism 2, said nut transmission mechanism 2 includes arrangement components 21 symmetrically arranged on both sides of said raw material transmission mechanism 1 and arranged in the same direction as said raw material transmission mechanism 1, and arranged at the output end of said arrangement assembly 21 Intermittent component 22; and

[0067] An automatic assembly mechanism 3, the automatic assembly mechanism 3 includes a forming assembly 31 arranged between the workpiece feeding assemblies 11, a...

Embodiment 2

[0110] Such as Figure 16 , Figure 15 As shown, the components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0111] Further, such as Figure 16 , Figure 15 As shown, the first transmission assembly 34 includes:

[0112] The linkage a341 is symmetrically arranged on both sides of the pusher assembly 32 and is mounted on the mounting seat 311, and includes a leg a3411, a rotating shaft d3412 that is rotatably arranged on the leg a3411 A gear b3413 coaxially and fixedly arranged with the rotating shaft d3412, a gear c3414 coaxially and fixedly arranged with the gear b3413, and a rack b whose one end is fixedly connected to the intermittent component 22 and meshes with the gear b3413 to rotate; as well as

[0113] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com