A wet sorting device for mixed garbage

A treatment device and separation treatment technology, applied in the direction of solid separation, mechanical material recovery, solid waste removal, etc., can solve the problems of odor spread, unimaginable consequences, easy to produce greenhouse effect, etc., and achieve low-cost garbage separation and recycling treatment , The effect of solving social pain points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

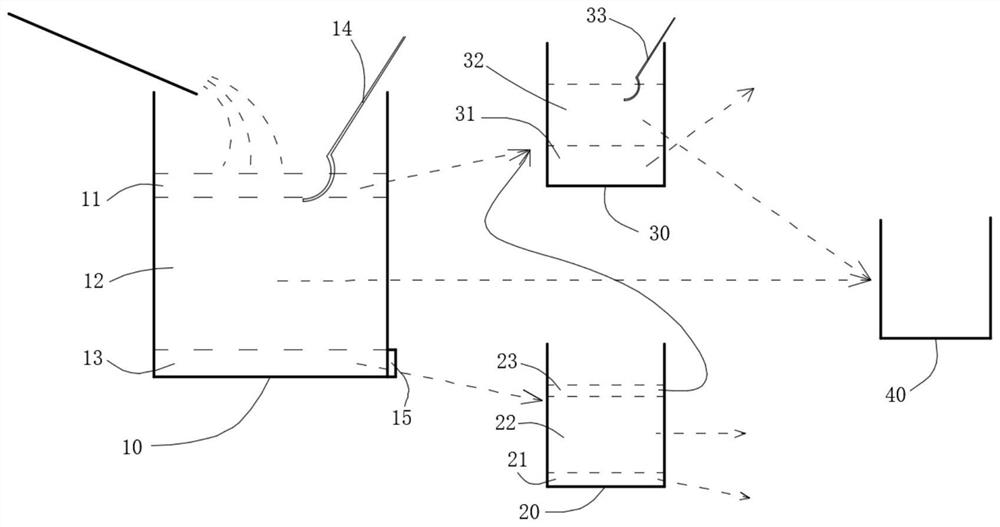

[0011] use as figure 1 In the process and method shown, the mixed garbage is first put into the wine raffinate alcohol-water medium separation container 10 whose separation medium is a wine raffinate-alcoholic water mixture with an average density of 0.95kg / L-1kg / L, and is subjected to simple and extensive mechanical stirring. Finally, the alcohol-soluble and water-soluble substances (sugar, grease, etc.) in the mixed garbage enter the solution to form an alcohol-water mixed solution layer 12, and then the light garbage (foamed plastics, bamboo and wood materials, etc.) Float on the surface of the solution to form a light insoluble garbage layer 11, and other garbage with a density higher than that of the brewing raffinate sinks at the bottom of the solution to form a heavy insoluble garbage layer 13, and use the first separating filter spoon 14 to separate the light insoluble garbage layer 11 and put it into In the internally closed hot-melt separation container 30 with a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com