Combined biomass gasification device and biomass gasification method

A gasification device and biomass technology, applied in the direction of gasification process, granular/powdered fuel gasification, and production of combustible gas, can solve the problems of poor fluidization state, high tar content, low energy utilization rate, etc., and achieve Optimize technical solutions, strengthen gasification efficiency, and improve the effect of high-efficiency gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

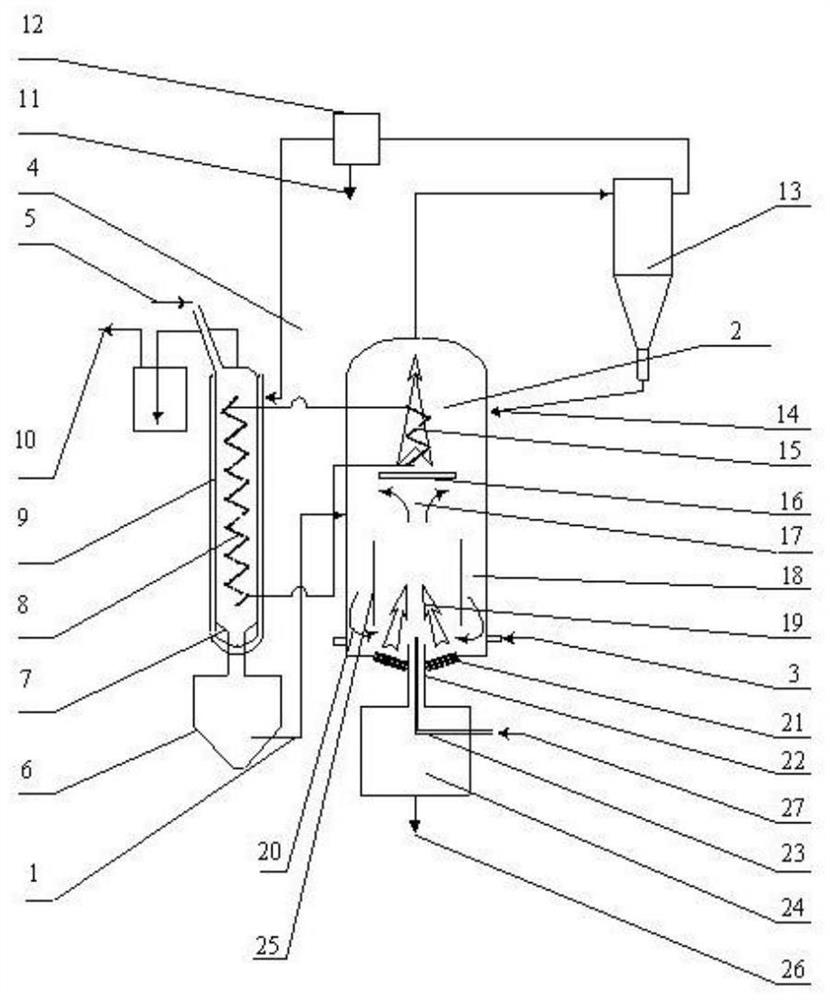

[0027] Such as figure 1 , combined biomass gasification device, the gasification device includes:

[0028] A pyrolysis furnace 9 for biomass pyrolysis, a gasification furnace 2 for receiving and gasifying raw materials after being pyrolyzed by the biomass pyrolysis furnace 9, and a thermal cyclone separator 13, and the interior of the gasification furnace 2 is arranged from top to bottom There are baffles 16 and gasifier ring-type baffles 25, thus the inside of the gasifier 2 is divided into a particle circulation return zone 17 below the baffle 16 and above the gasifier ring-type baffles 25, Particle circulation descending area 18 outside the annular baffle 25, particle central gasification area 19 inside the gasifier annular baffle 25, particles under the particle circulation descending area 18 and the bottom of the gasifier annular baffle 25 Circulation feed area 20, wherein, particle circulation downlink area 18, particle center gasification area 19, and particle circulat...

Embodiment 2

[0038] Such as figure 1 , combined biomass gasification device, the gasification device includes:

[0039] A pyrolysis furnace 9 for biomass pyrolysis, a gasification furnace 2 for receiving and gasifying raw materials after being pyrolyzed by the biomass pyrolysis furnace 9, and a thermal cyclone separator 13, and the interior of the gasification furnace 2 is arranged from top to bottom There are baffles 16 and gasifier ring-type baffles 25, thus the inside of the gasifier 2 is divided into a particle circulation return zone 17 below the baffle 16 and above the gasifier ring-type baffles 25, Particle circulation descending area 18 outside the annular baffle 25, particle center gasification area 19 inside the gasifier annular baffle 25, particles under the particle circulation descending area 18 and the bottom of the gasifier annular baffle 25 Circulation feed area 20, wherein, particle circulation downlink area 18, particle center gasification area 19, and particle circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com