Device for pre-detecting aging degree of cable before laying

An aging degree, cable laying technology, applied in measuring devices, chemical instruments and methods, using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve problems such as hidden safety hazards, high cable temperature, cable aging, etc. The effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

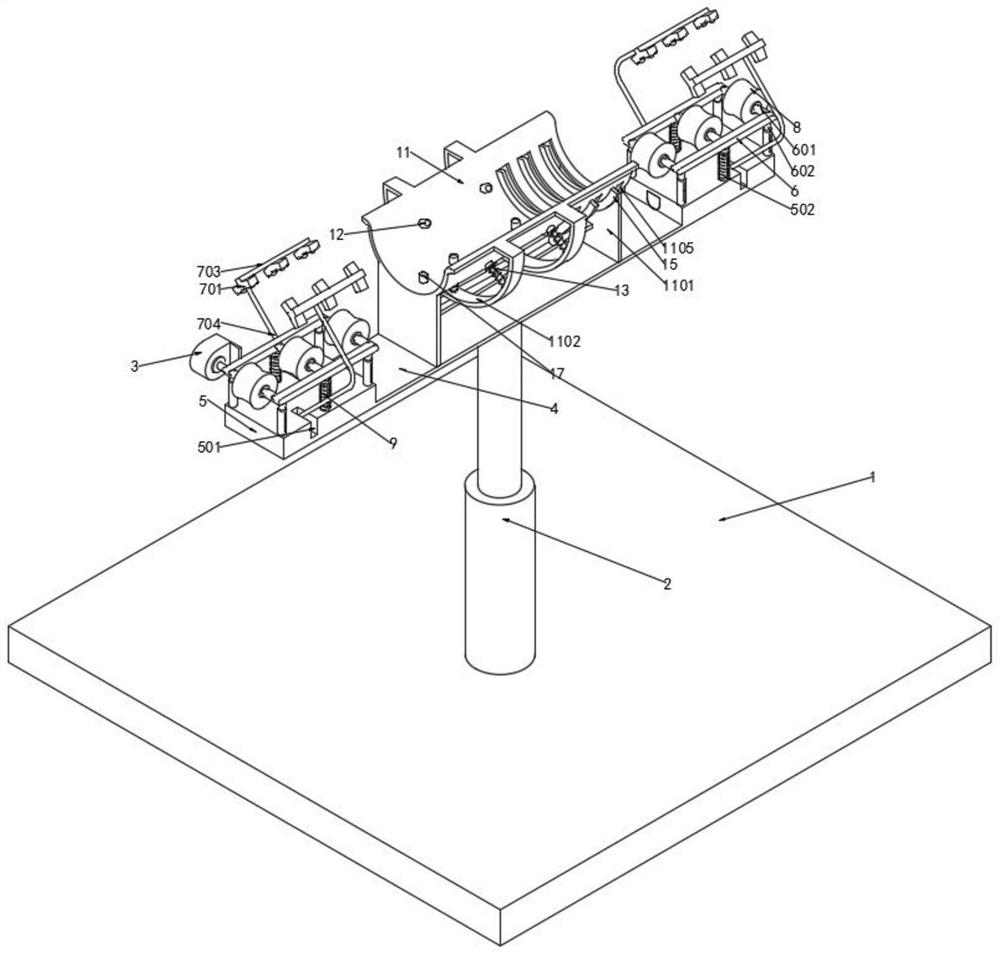

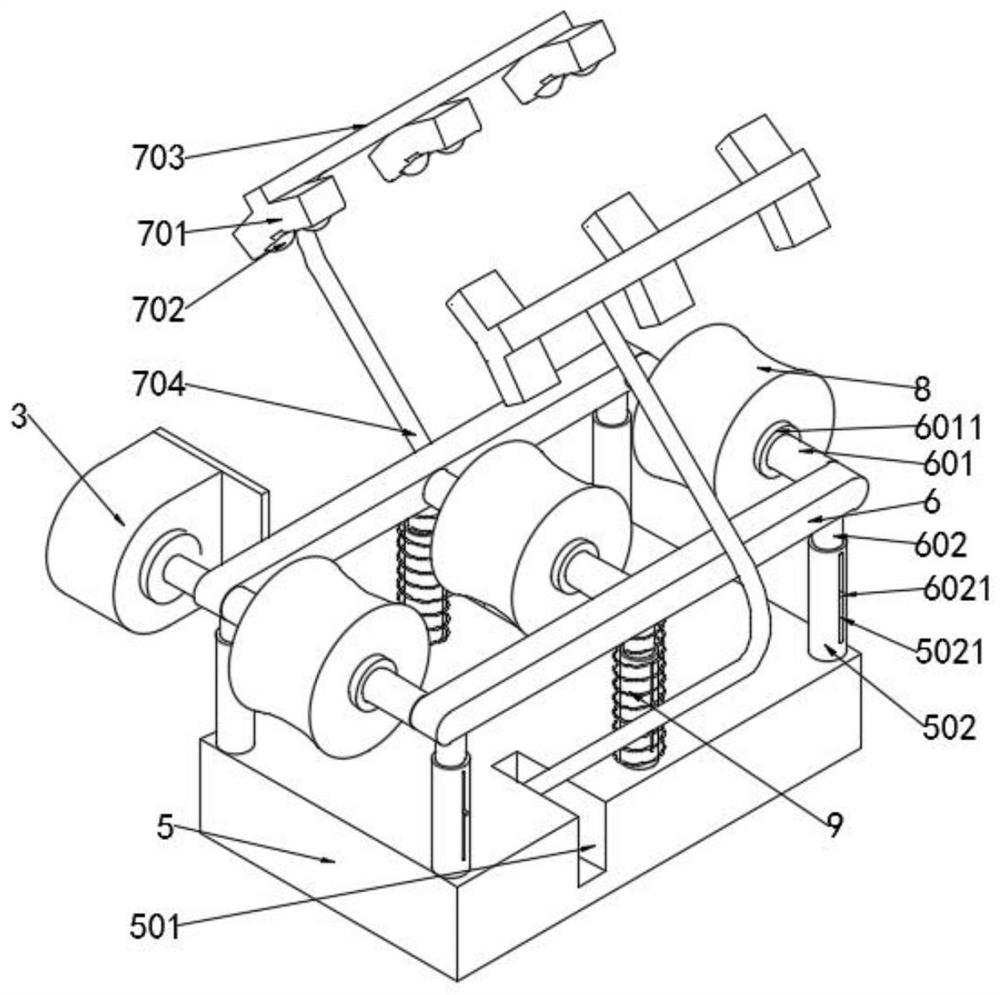

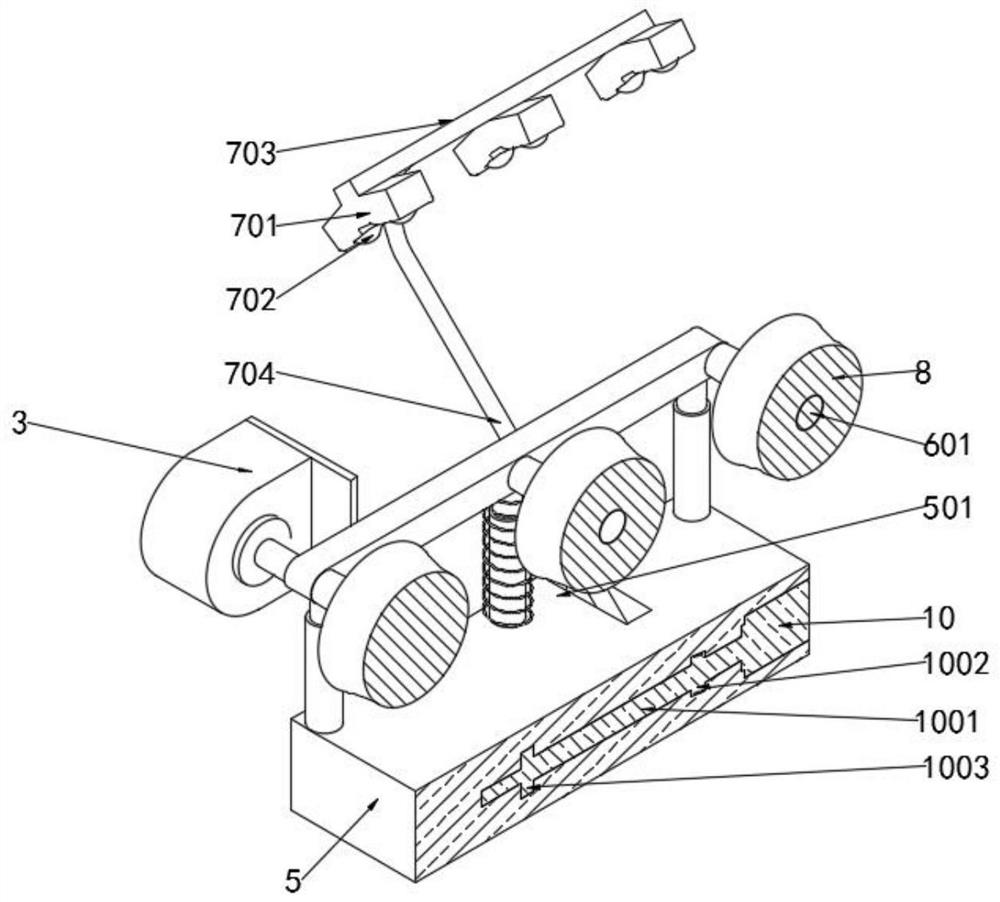

[0079] The attached drawing is the best embodiment of the device for pre-checking the aging degree of the cable before it is laid, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0080] attached by figure 1 To attach Figure 10 As shown, a device for pre-inspecting the aging degree of cables before laying includes a main control computer and a seat board 1. For portability, the main control computer is a notebook computer.

[0081] A first connecting rod 2 is fixed above the seat plate 1 , and a first support plate 4 is fixed at the end of the first connecting rod 2 .

[0082] A cable detection device is provided in the middle of the top of the first support plate 4 , and at least one of the two sides of the cable detection device is provided with a cable hooking device. In this embodiment, in order to increase the clamping degree of the cable, a set of cable hooking devices are provided on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com