Lightweight method of riveting structure

A riveting structure, lightweight technology, applied in the field of creation belongs to the automotive field, can solve problems such as unreasonable riveting spacing, and achieve the effects of improving product competitiveness, avoiding structural improvement, and reducing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0052] The invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

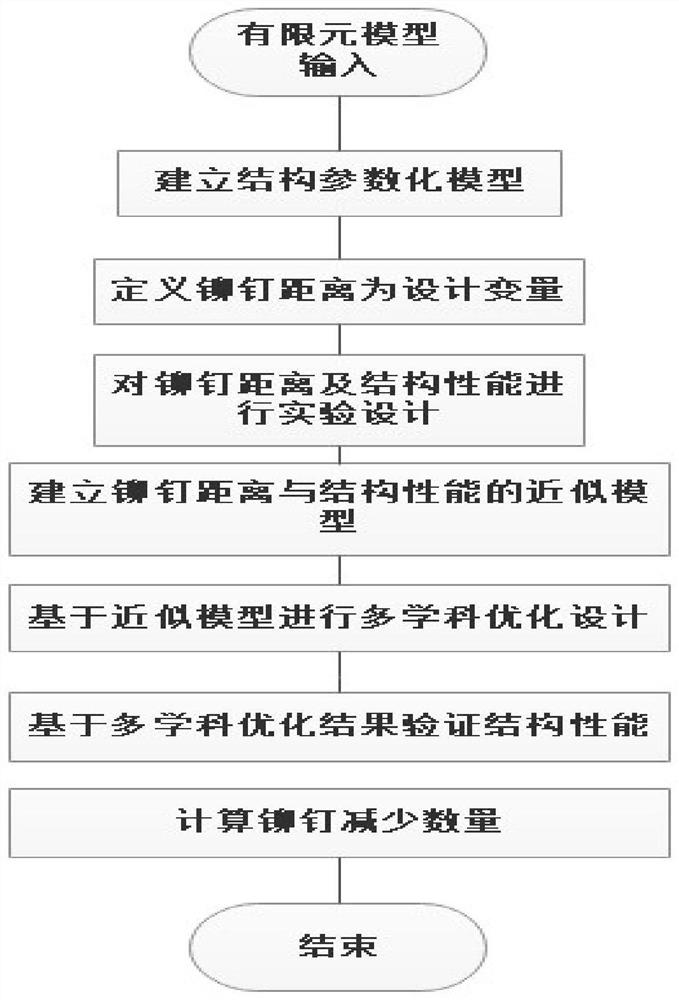

[0053] The invention discloses a lightweight method for a riveted structure, such as figure 1 As shown, taking the steel-aluminum mixed body-in-white structure of a passenger car as an example, the specific implementation process of the lightweight method of the present invention is as follows:

[0054] Step 1: Using the BIW finite element model as input, determine the steel-aluminum riveting structure area;

[0055]In this step 1, the body-in-white finite element s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com