Hinge static strength test clamping device and system

A clamping device and static strength technology, which is applied in the field of iron and steel metallurgy, can solve the problems of interfering with new materials, new processes, new structure analysis and judgment, and affecting the load-displacement relationship. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

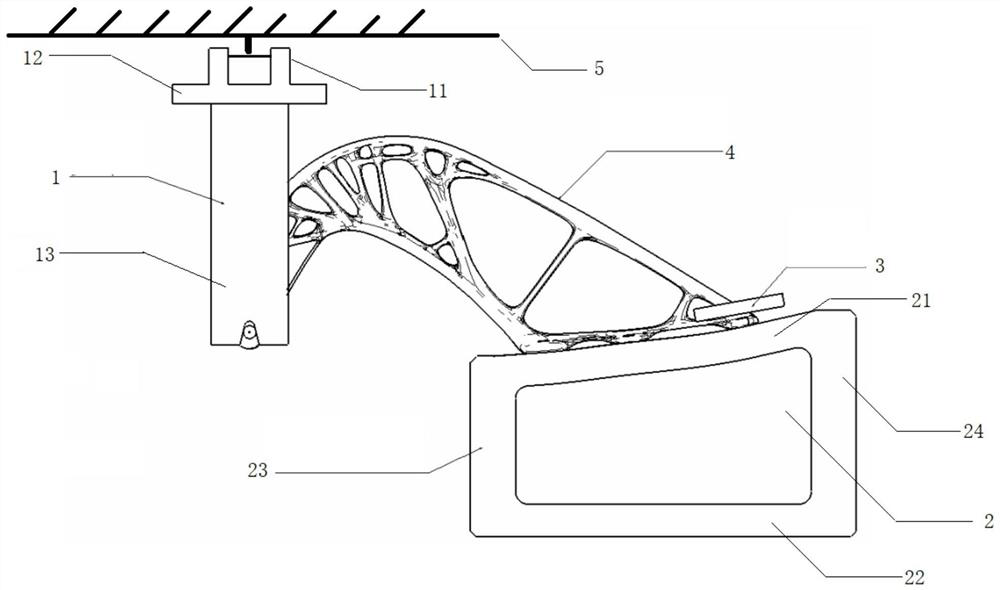

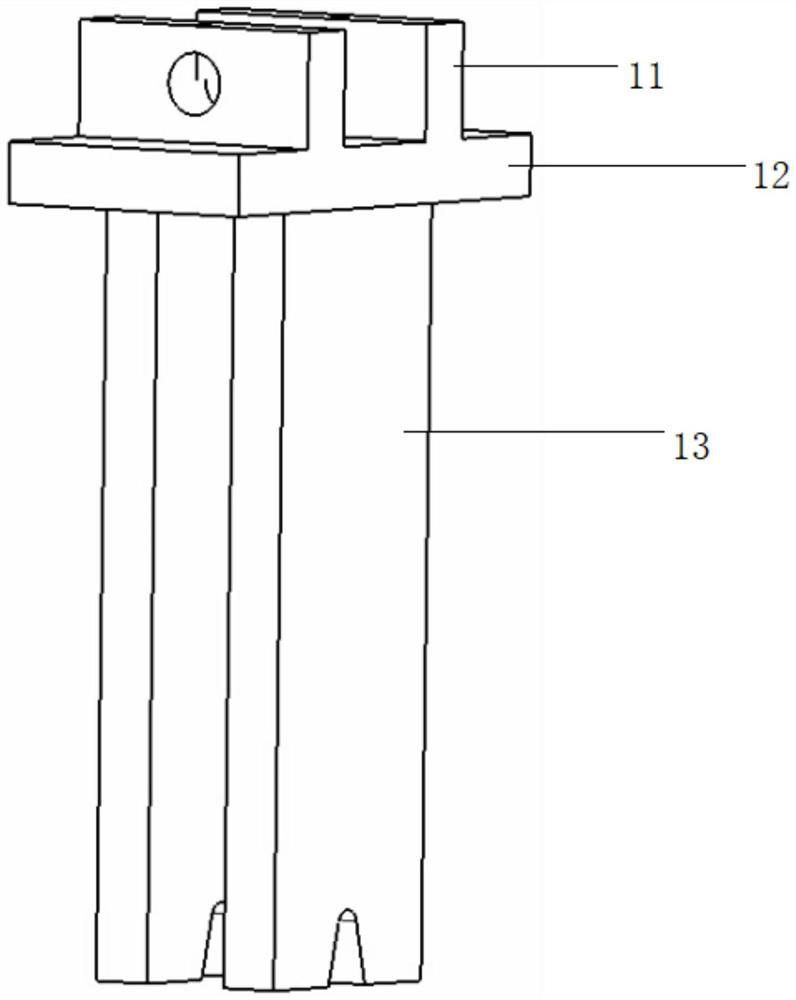

[0052] The invention is used for the verification of the hinge bearing capacity test and the static strength analysis method, and can ensure the reasonable load transmission of the test piece and prevent the analysis method from being interfered by the displacement error of the connection part. In the present invention, the loading end clamp 1 , the base support 2 , the clamping plate 3 , and the components are mechanically connected to form an assembly relationship. The loading end fixture 1 is loaded through a dowel bar through the connecting hole of the test piece 4, and the fixture 1 at the loading end is designed to load the dowel bar with downward force. The upper end of the loading end fixture 1 is connected to the loading testing machine 5, and the lower end is designed with a U-shaped groove to load the screw.

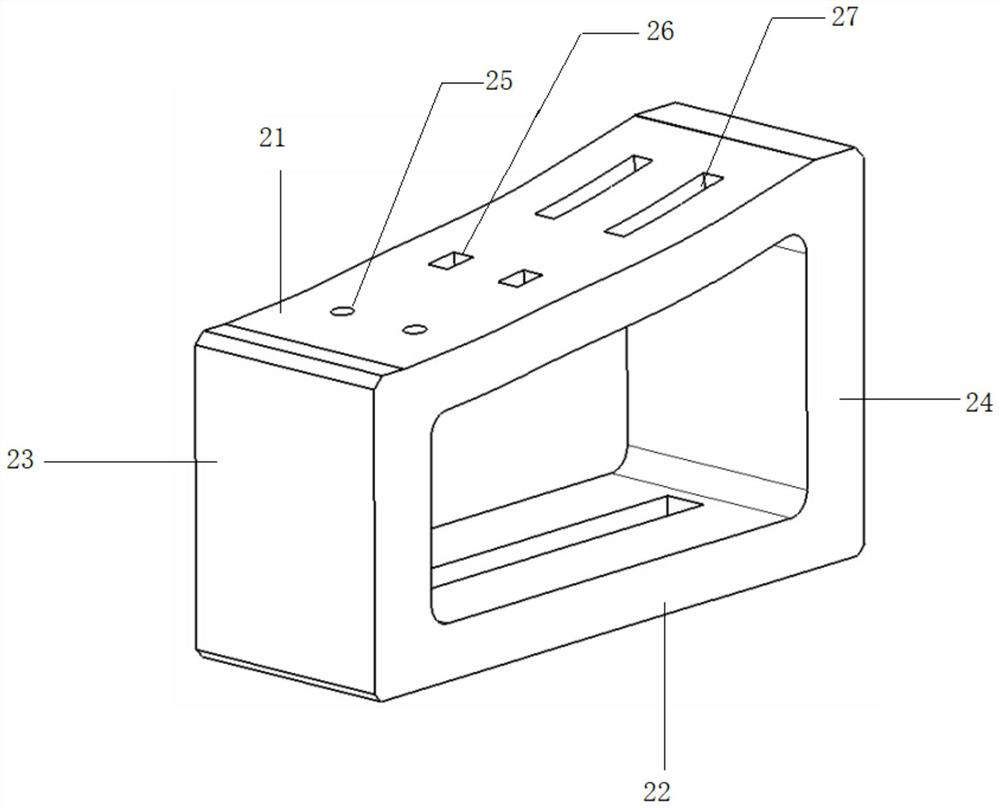

[0053] The base support 2 has sufficient rigidity, the thickness of the upper and lower connecting surfaces is designed to be 25mm, and the thickness of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com