An automatic grinding device for zirconium tungstate powder

A grinding device and technology of zirconium tungstate, applied in the field of ceramic materials, can solve the problems of high cost of grinding equipment, adverse effects of zirconium tungstate functional ceramic body production, unsatisfactory grinding efficiency, etc., and achieve simple structure, low equipment cost, and high grinding efficiency. Adjustable pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

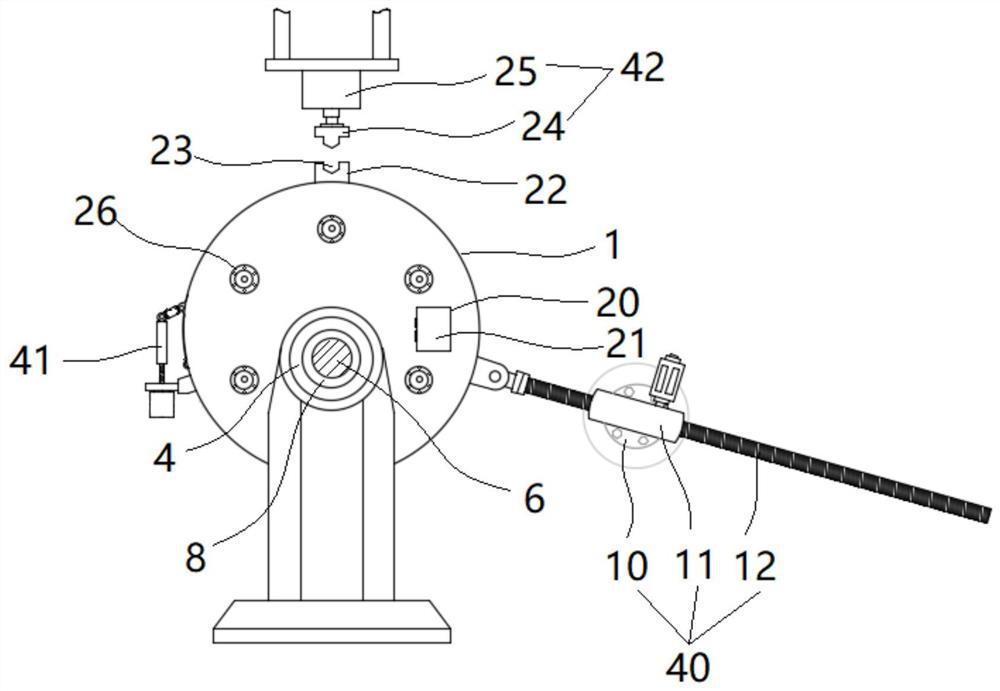

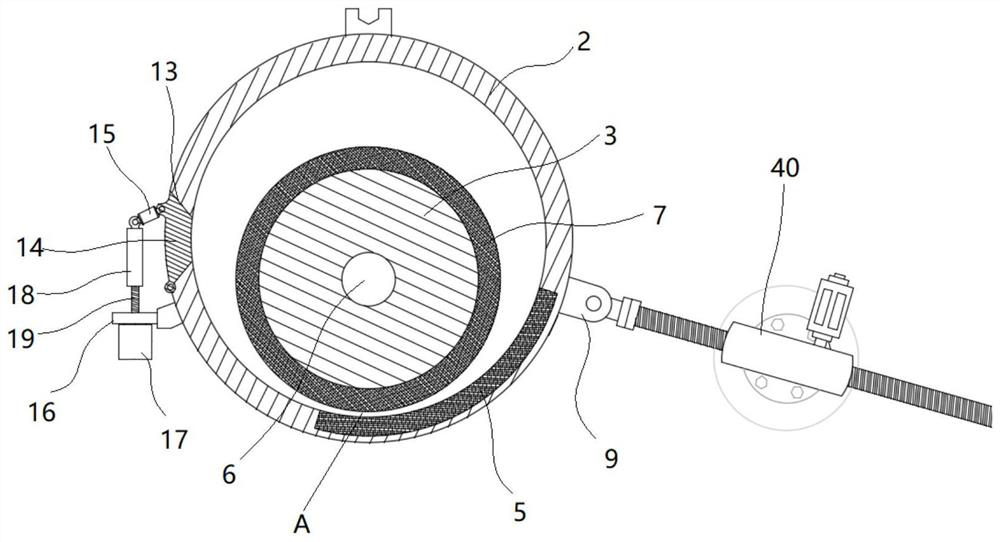

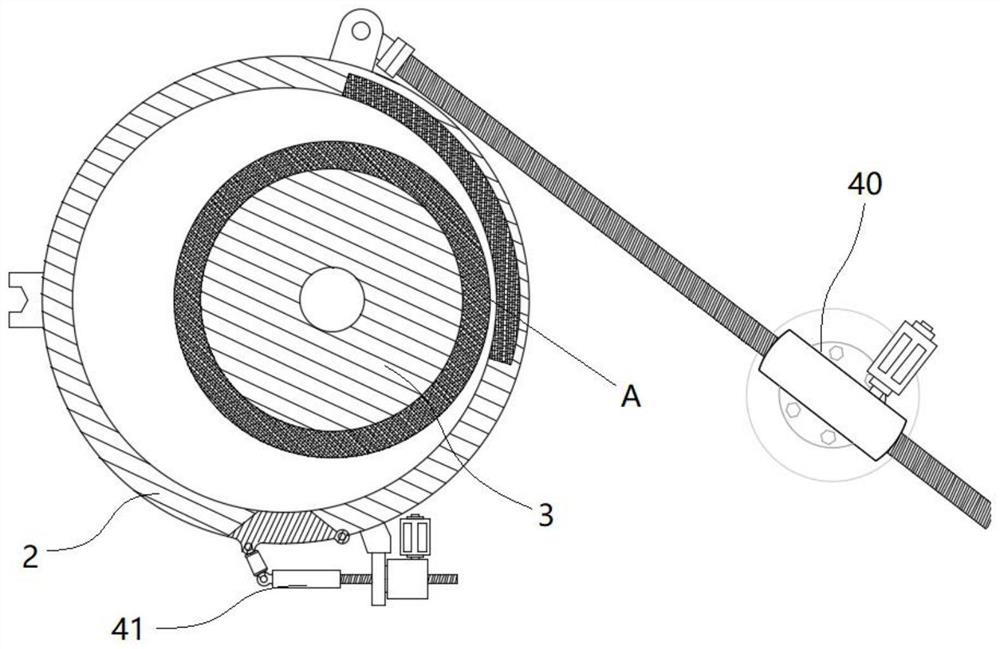

[0032] An automatic grinding device for zirconium tungstate powder in this embodiment is characterized in that it includes a grinding tank 1, the grinding tank 1 is composed of a shell 2 and a grinding disc 3, the shell 2 is a hollow cylinder, And the axis of the cylinder is horizontal, the horizontal sides of the housing 2 are provided with symmetrical shaft holes 4, and the housing 2 is embedded with an arc-shaped first grinding block 5, and the grinding disc 3 is cylindrical. shape, and the axis of the cylindrical shape is horizontal, it is arranged in the housing 2, the middle part of the grinding disc 3 is fixedly connected to the grinding spindle 6, and the cylindrical outer wall of the grinding disc 3 is provided with a circular second grinding block 7;

[0033] The shaft hole 4 is eccentrically arranged, and its axis is not on the same straight line as the axis of the housing 2. The shaft hole 4 is provided with a sealed bearing 8, and the housing 2 and the grinding sp...

Embodiment 2

[0040] A kind of zirconium tungstate powder automatic grinding device of the present embodiment is characterized in that, the working method of this automatic grinding device is as follows:

[0041] (1) Feeding: Open the feeding hopper on the shell, send the zirconium tungstate powder to be ground into the grinding tank from the feeding port, and then close the feeding hopper;

[0042] (2), grinding;

[0043](2-1) Constant pressure grinding: start the rotating mechanism, drive the screw sleeve to work, drive the telescopic screw to expand and contract, and then control the housing to rotate to a certain angle. At this time, the minimum gap between the first grinding block and the second grinding block is located The position A changes and finally solidifies, the grinding pressure is constant, then the drive mechanism is started, the grinding spindle rotates, and the grinding of zirconium tungstate powder begins;

[0044] (2-2) Pressure-changing grinding: start the driving mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com