Dispensing equipment and dispensing method for LED nixie tube producing and processing

An LED digital tube and glue dispensing technology, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of no storage location of the equipment, difficult real-time control, and accidental touch, so as to reduce trouble and enhance use. Flexibility, easy operation and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

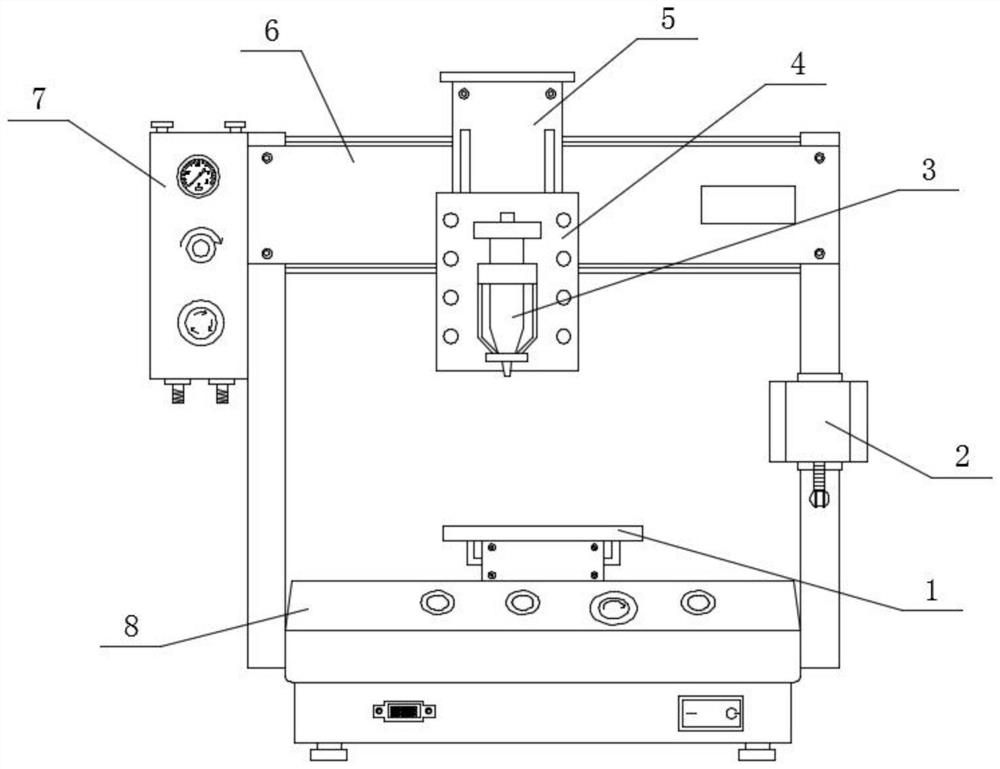

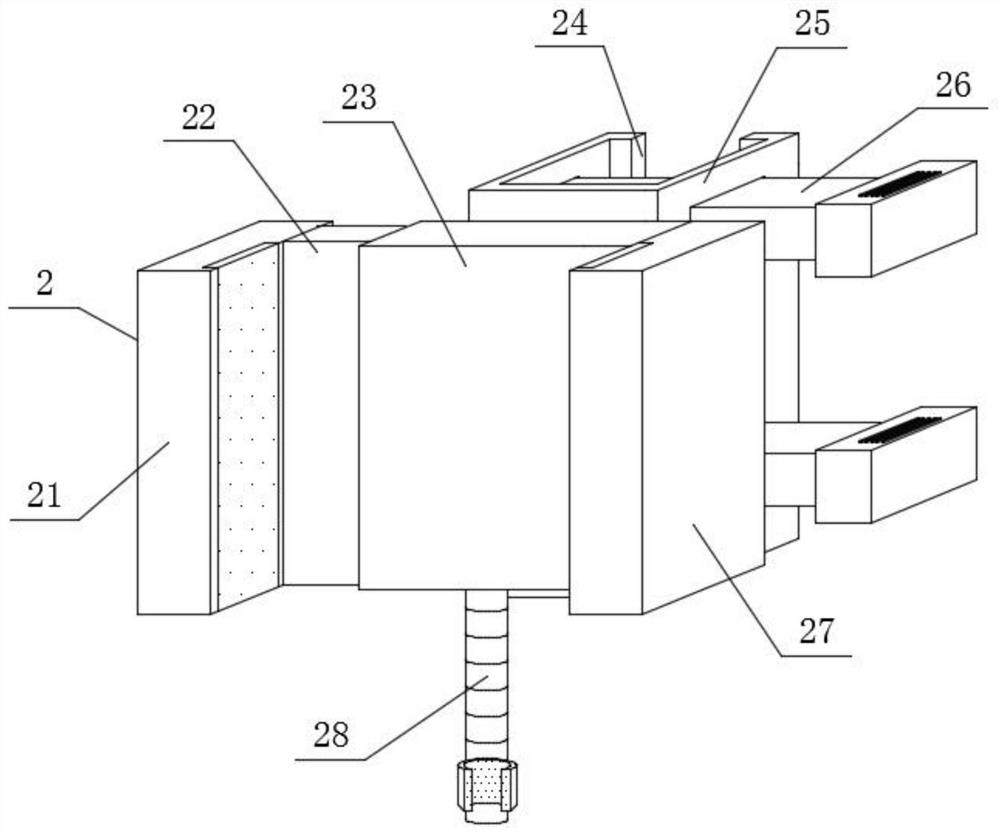

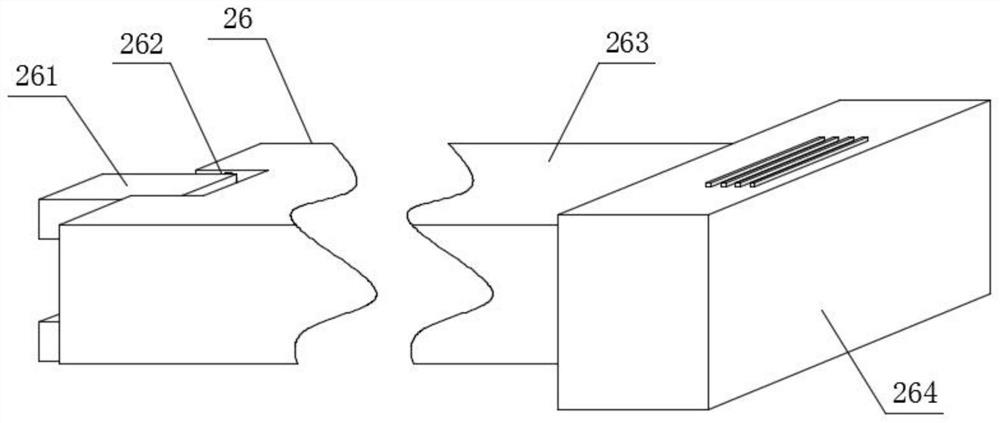

[0027] Such as Figure 1-2 As shown, a dispensing equipment for the production and processing of LED digital tubes includes a lower body 8, the top of the lower body 8 is fixedly connected with a workbench 1, and the side end of the lower body 8 is fixedly connected with an upper body 6, and the upper body 6 The outer surface is socketed and movably connected with a clamp 2, and the left end of the upper body 6 is fixedly connected with a control panel 7, and the position above the front end of the upper body 6 is connected with a horizontal axis connecting block 5 through a screw drive, and the front end of the horizontal axis connecting block 5 The flat plate 4 is slidingly connected, the front end of the flat plate 4 is fixedly connected with the rubber outlet pipe 3, the clamp 2 includes a rear splint 23, the right end of the rear splint 23 is plugged and connected with a right splint 27, and the left end of the rear splint 23 is connected with a flexible connection Connec...

Embodiment 2

[0030] Such as Figure 1-3 As shown, a dispensing equipment for the production and processing of LED digital tubes includes a lower body 8, the top of the lower body 8 is fixedly connected with a workbench 1, and the side end of the lower body 8 is fixedly connected with an upper body 6, and the upper body 6 The outer surface is socketed and movably connected with a clamp 2, and the left end of the upper body 6 is fixedly connected with a control panel 7, and the position above the front end of the upper body 6 is connected with a horizontal axis connecting block 5 through a screw drive, and the front end of the horizontal axis connecting block 5 The flat plate 4 is slidingly connected, the front end of the flat plate 4 is fixedly connected with the rubber outlet pipe 3, the clamp 2 includes a rear splint 23, the right end of the rear splint 23 is plugged and connected with a right splint 27, and the left end of the rear splint 23 is connected with a flexible connection Connec...

Embodiment 3

[0033] Such as Figure 1-4 As shown, a dispensing equipment for the production and processing of LED digital tubes includes a lower body 8, the top of the lower body 8 is fixedly connected with a workbench 1, and the side end of the lower body 8 is fixedly connected with an upper body 6, and the upper body 6 The outer surface is socketed and movably connected with a clamp 2, and the left end of the upper body 6 is fixedly connected with a control panel 7, and the position above the front end of the upper body 6 is connected with a horizontal axis connecting block 5 through a screw drive, and the front end of the horizontal axis connecting block 5 The flat plate 4 is slidingly connected, the front end of the flat plate 4 is fixedly connected with the rubber outlet pipe 3, the clamp 2 includes a rear splint 23, the right end of the rear splint 23 is plugged and connected with a right splint 27, and the left end of the rear splint 23 is connected with a flexible connection Connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com