Device for hot melting welding of plastic hoses

A technology of hot-melt welding and plastic hoses, which is applied in applications, household appliances, tubular objects, etc., and can solve problems such as low connection efficiency, human injury, and pipe burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

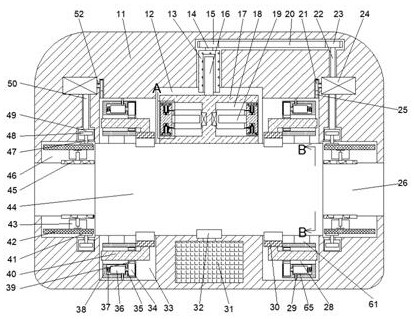

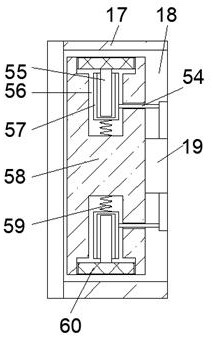

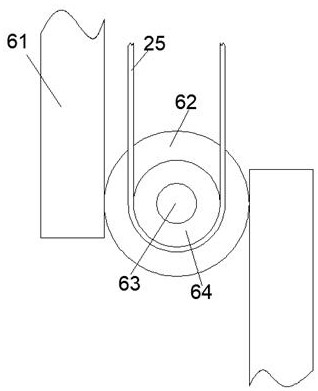

[0015] Combine below Figure 1-3 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] A device for hot-melt welding of plastic hoses according to the present invention includes a frame 11, a working cavity 44 is arranged inside the frame 11, two ends of the working cavity 44 are connected to each other and provided with two Cavities 26, the two protruding cavities 26 are symmetrically distributed with the center of the working cavity 44 as the symmetrical center, the end of the protruding cavity 26 away from the working cavity 44 runs through the frame 11, the protruding cavity The upper and lower sides of the inner wall of the inlet cavity 26 are respectively connected with two storage cavities 46. The two storage cavities 46 are symmetrically distributed up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com