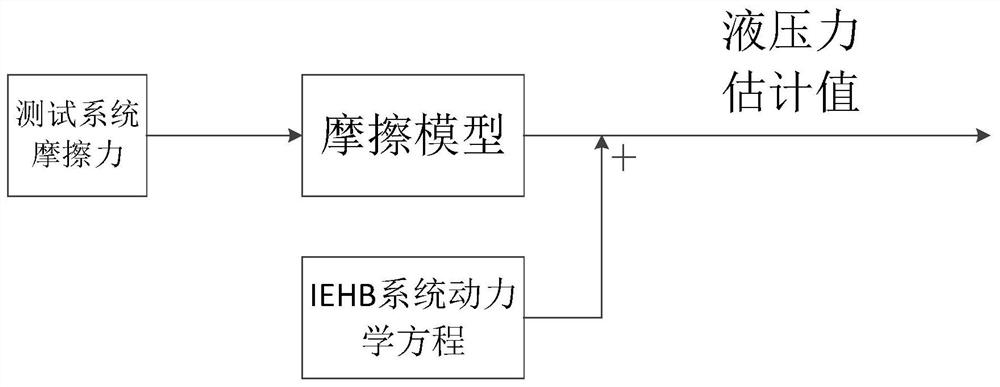

Estimation Method of Master Cylinder Hydraulic Pressure Based on Friction Model

A friction model and hydraulic pressure technology, applied in braking safety systems, vehicle components, brakes, etc., can solve problems such as friction modeling that needs further research, reduce identification test workload, improve failure safety, and the method is reasonable workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

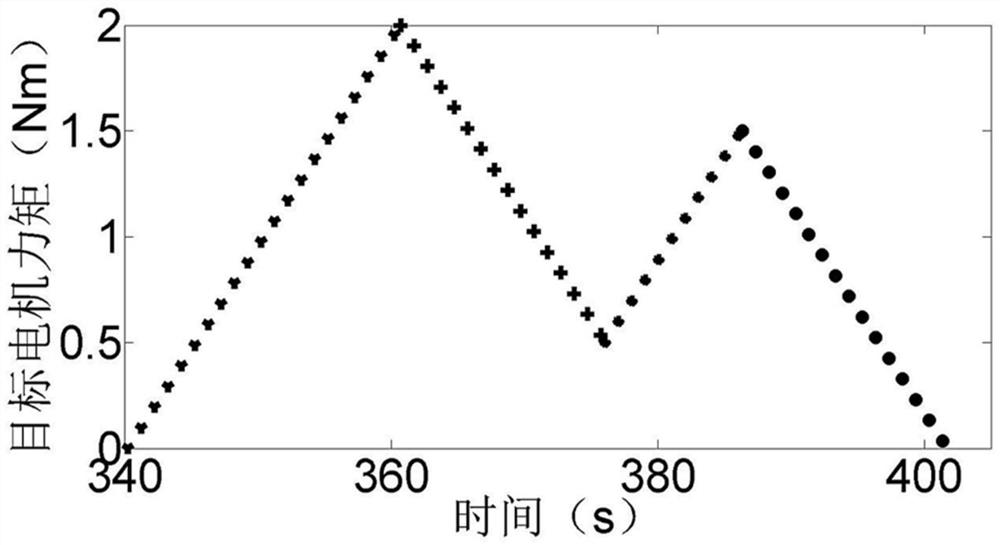

Examples

Embodiment

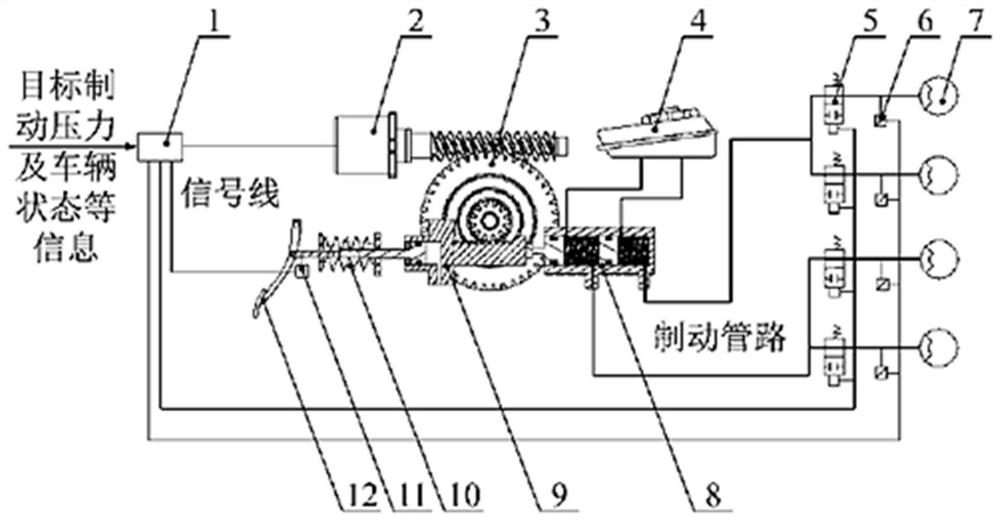

[0031] The present invention relates to a method for estimating the hydraulic pressure of the main cylinder of the IEHB system based on a friction model. The main structure of the IEHB system used in this embodiment is as follows figure 1 shown, which includes:

[0032] Brake pedal unit: including the brake pedal 12 assembly, reflecting the driver's driving intention;

[0033] Active pressure building unit: including motor (permanent magnet synchronous motor 2 in this embodiment), worm gear and rack and pinion (reduction transmission mechanism 3 in this embodiment), used to convert the rotational torque of the motor into The translational thrust of the master cylinder is pushed to generate the corresponding brake fluid pressure;

[0034] Brake execution unit: including brake master cylinder 8, brake wheel cylinder 7, solenoid valve (normally open solenoid valve 5 in this embodiment), liquid storage tank 4 and hydraulic pipelines, used to drive the gear of the active pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com