Method for improving space utilization of container ship, fastening device for container ship

A container ship and fastening device technology, which is applied to the container ship fastening device, provides the container ship loading rate, and the transportation field of non-standard containers, can solve the problems of cumbersome operation process, non-standard container damage, extra conversion beams, etc. The operation process is simple and efficient, the applicability is improved, and the circulation range is expanded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

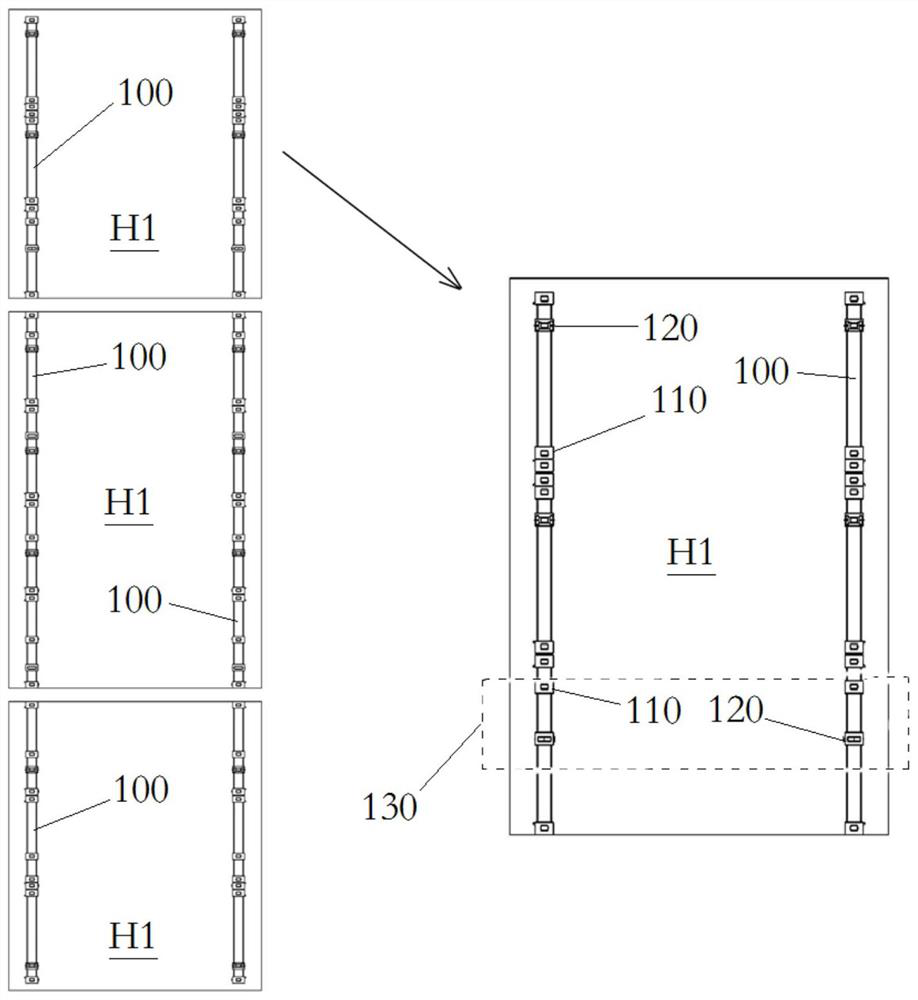

[0142] This embodiment provides a method for improving the utilization rate of container ship spaces, such as image 3 As shown, taking the main body guide rails distributed horizontally as an example, the method includes: providing several pairs of main body guide rails 100 distributed along the transverse direction of the container ship, and several pairs of main body guide rails 100 are distributed on different hatch covers H1, E.g image 3 The situation in which several pairs of main body guide rails 100 are distributed on three hatch covers shown in FIG.

[0143] The main body rail 100 adopts such as Figure 16 , 17 For the stepped guide rails shown, the length of all the stepped guide rails is 2448 mm, and a pair of standard fastening seats 214 and standard fastening holes 213 are fixed symmetrically on the top and bottom of the main body guide rail 100, and the standard fastening seats / holes The center distance is 2259 millimeters from the center distance of the corn...

Embodiment 2

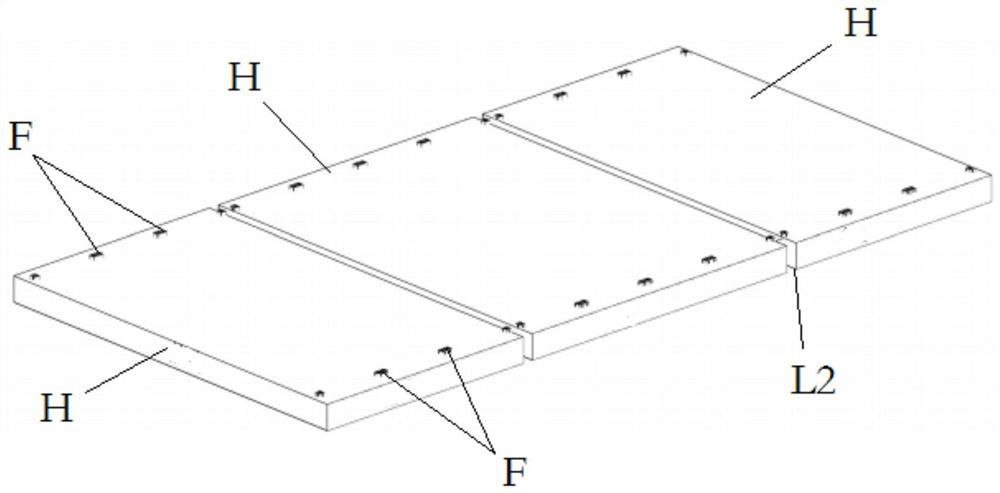

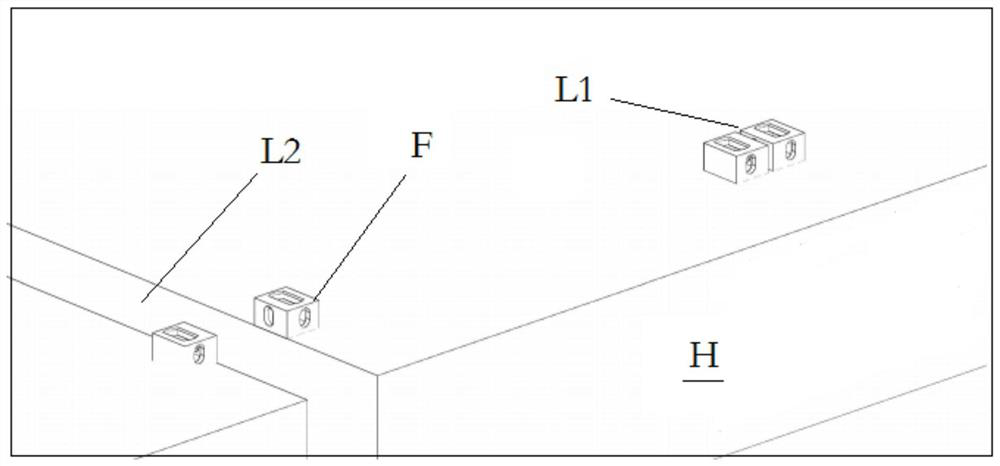

[0148] This embodiment provides a container ship fastening device, such as Figure 4 As shown, the container ship fastening device includes several main body guide rails 210, the length of all main body guide rails is 2448 mm, the main body guide rails 210 are distributed along the berth width direction of the container ship, and the main body guide rails 210 are fixed in pairs, side by side, closely adjacent to each other. On the hatch cover H2 of the ship;

[0149] The standard fastening seat 214 symmetrically fixed on the top of the main body guide rail 210 is used to correspond to the corner fittings at the bottom of the standard container for fastening connection. Corresponding to the corner fittings or standard container corner fittings for fastening connection;

[0150] A plurality of fastening connection structures arranged on the same pair of main body guide rails 210 or on an adjacent pair of main body guide rails 210 includes two first fastening seats 220 and two f...

Embodiment 3

[0161] This embodiment provides a container ship fastening device, such as Figure 18 As shown in -22, the difference between this embodiment and embodiment 2 lies in that the applicable ship types are different.

[0162]Also take the intensive loading of 45-foot ultra-wide 2500mm non-standard containers on the same 40-foot hatch cover as an example. The assumption of loading is that there is a lashing bridge between adjacent monuments on the ship. Due to the limitation of length and space, it can only be used on two floors. The non-standard container is loaded on the standard container, that is, a 40-foot monument has two hatch covers, and 5 standard containers are placed on each hatch cover from left to right, and each group of corner fittings in the same hatch cover is adjacent to each other. The gap is 38 mm, that is, the distance between the centers of adjacent holes is 216 mm, and the distance between different hatch covers is 418 mm. It can be stacked in 4 layers, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com