A kind of production method and production line of mug cup food

A production method and technology for mother and daughter cups, which are applied in the types of packaging items, transportation and packaging, liquid materials, etc., can solve the problems of stringing cups, reducing product quality, affecting user eating experience, etc., so as to reduce production costs and improve production efficiency. , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

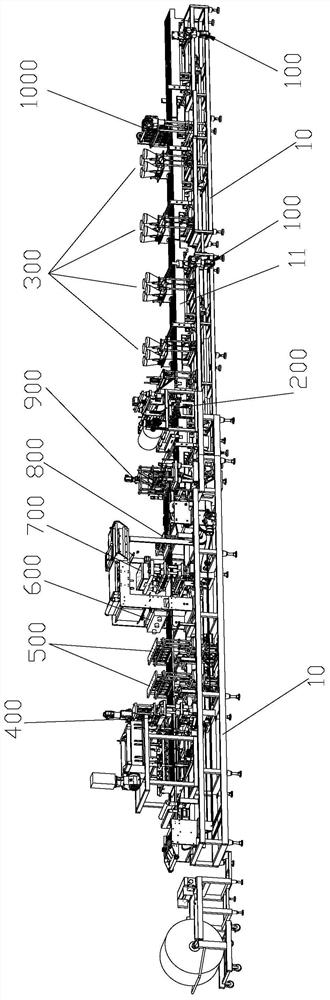

[0052] The technical solutions of the embodiments of the present invention will be explained and described below with reference to the accompanying drawings of the embodiments of the present invention, but the following embodiments are only preferred embodiments of the present invention, not all. Based on the examples in the implementation manner, other examples obtained by those skilled in the art without creative work shall fall within the protection scope of the present invention.

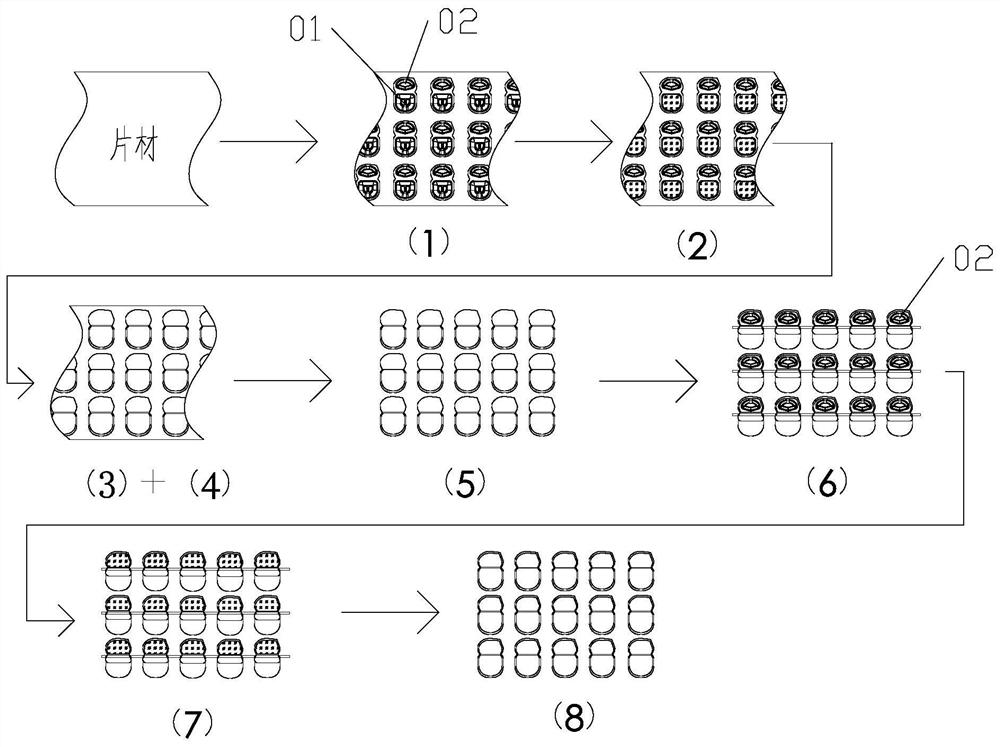

[0053] refer to Figure 1 to Figure 2 As shown, the production method of the child-mother cup food in the present embodiment comprises the following steps:

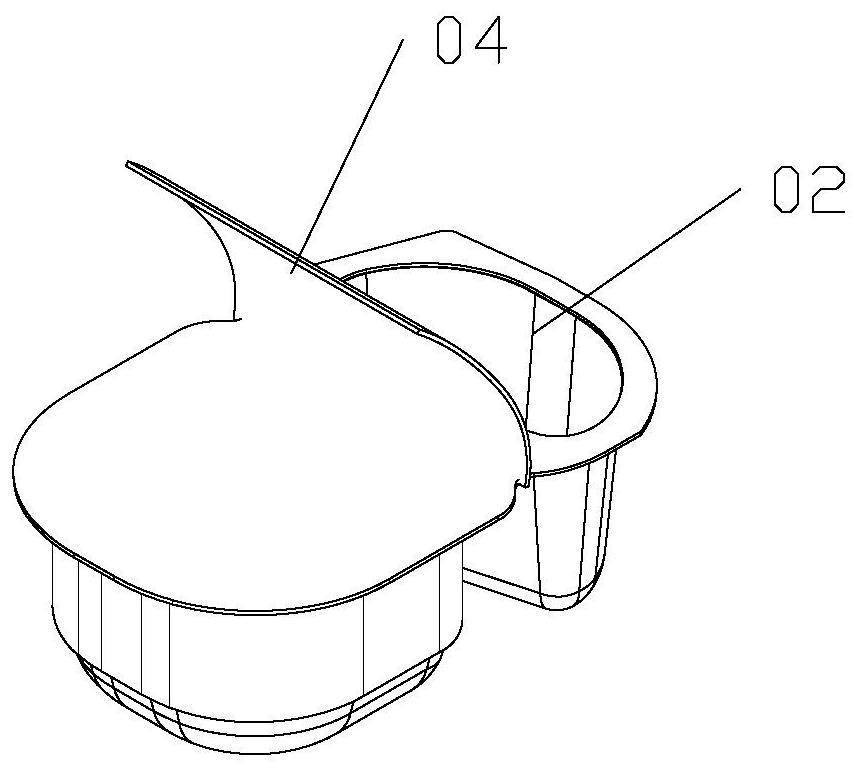

[0054] (1) Extrusion molding: the heated sheet is extruded to obtain a multi-cup product integrated with the sheet. The multi-cup product includes a plurality of cup bodies, and the cup body has a first cavity 01 and a second cavity 02 , and the extruded first cavity 01 and the second cavity 02 are distributed side by side in the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com