Forklift and operation method

A technology for forklifts and forks, which is applied in the field of forklifts and operations, can solve problems such as hidden dangers of safety and slippage of goods for handling forks, and achieve the effects of improving stability, increasing frictional resistance, and improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

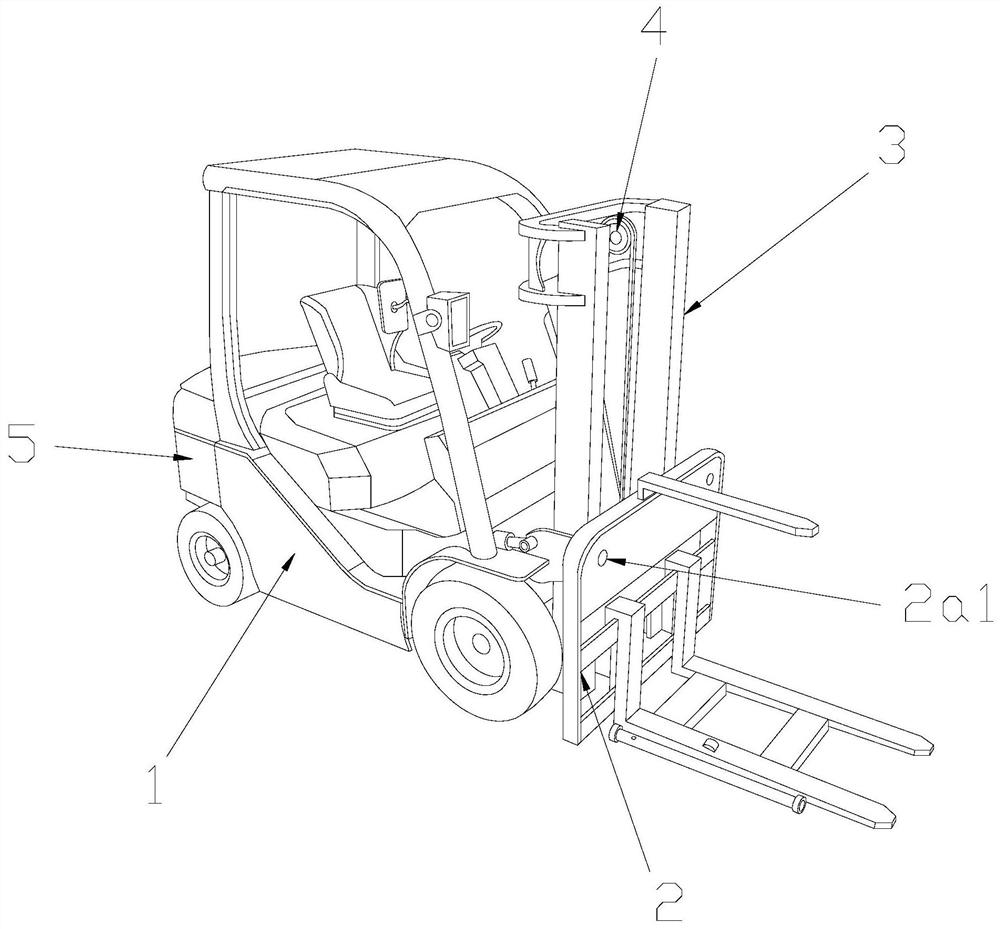

[0031] see Figure 1-Figure 5 , the present invention provides a forklift and its operation method, its structure includes a forklift 1, a forklift mechanism 2, a door frame 3, a driving device 4, and a balance weight 5, the front end of the forklift 1 is provided with a door frame 3, the The forklift 1 and the door frame 3 are mechanically connected, the door frame 3 is provided with a forklift mechanism 2, the door frame 3 and the forklift mechanism 2 are slidably matched by the driving device 4, and the rear end of the forklift 1 is A balance counterweight 5 is installed below;

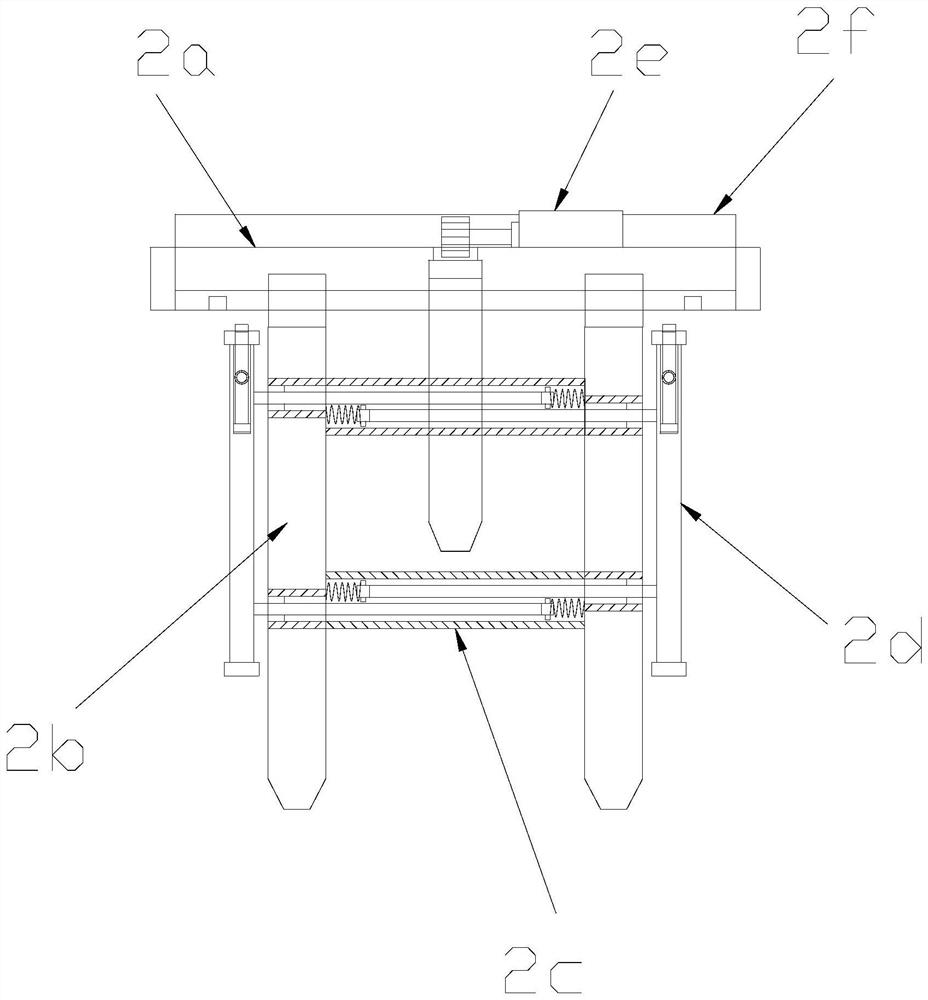

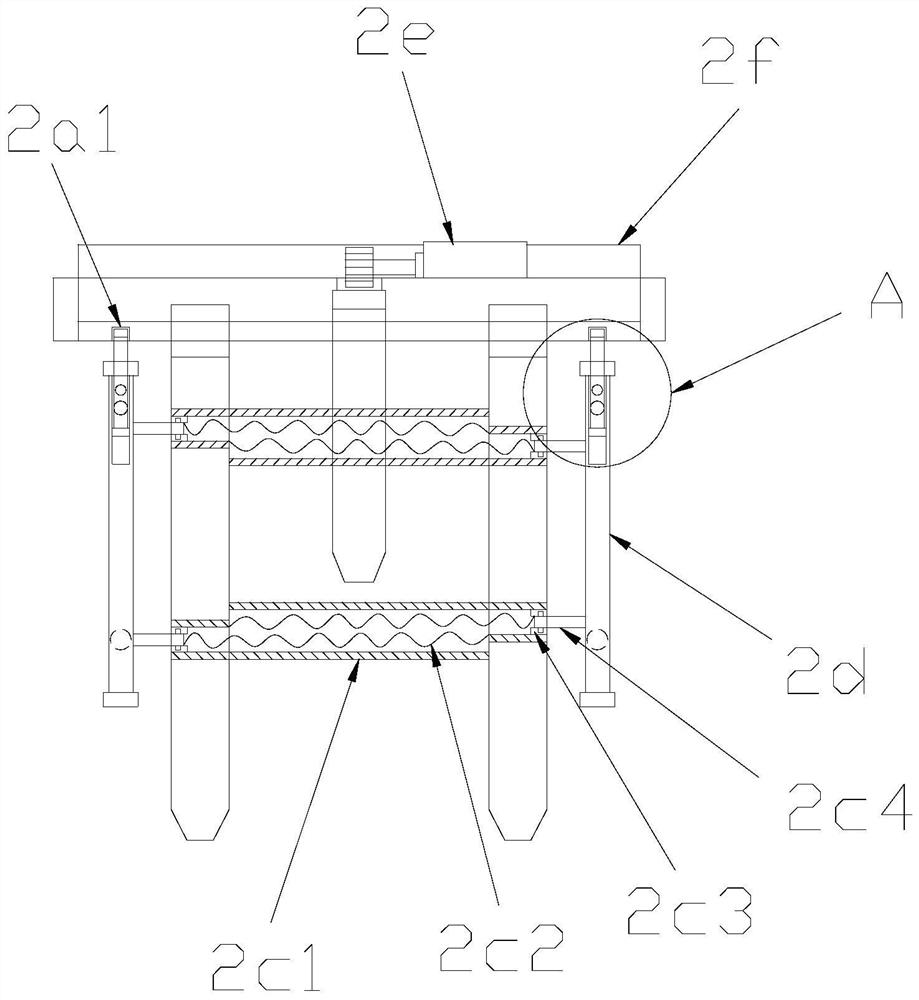

[0032] The forklift mechanism 2 is composed of a shelf 2a, a fork 2b, a storage mechanism 2c, a horizontal surrounding bar 2d, a fitting mechanism 2e, and a shock absorber 2f. Two forks are arranged on the front end of the shelf 2a 2b, the said shelf 2a is mechanically connected to the fork 2b, the storage mechanism 2c is installed between the said fork 2b and the fork 2b, and the left and right s...

Embodiment 2

[0041] see Figure 1-Figure 6 , the present invention provides a forklift and its operation method. The laminating mechanism 2e is composed of a motor 2e1, a gear shaft 2e2, a rack 2e3, and an L-shaped pressing bar 2e4. The motor 2e1 is provided with a gear shaft 2e2 on the surface, The motor 2e1 is mechanically connected to one end of the gear shaft 2e2, and the rear end surface of the L-shaped pressing rod 2e4 is provided with a rack 2e3, and the L-shaped pressing rod 2e4 and the rack 2e3 are of an integrated structure. The L-shaped pressing rod 2e4 is engaged with the pinion shaft 2e2 through the rack 2e3.

[0042] An anti-slip strip 2e41 is provided under the inner side of the head end of the L-shaped pressing bar 2e4, and the L-shaped pressing bar 2e4 is glued to the anti-slip bar 2e41.

[0043] The limiting bar 2c3 and the telescopic pull rod 2c41 are fastened together through the balance sliding column 2c42, the head end of the vertical surrounding rod 2c4 is welded to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com