Threaded grouting sleeve suitable for side-by-side connection of double parallel bars

A technique of grouting sleeves and double reinforcement, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as difficulties in concrete pouring, inability to obtain diameter steel bars or reinforcements, and inability to arrange, and achieve external dimensions and occupancy Small size, simple structure, easy to make and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

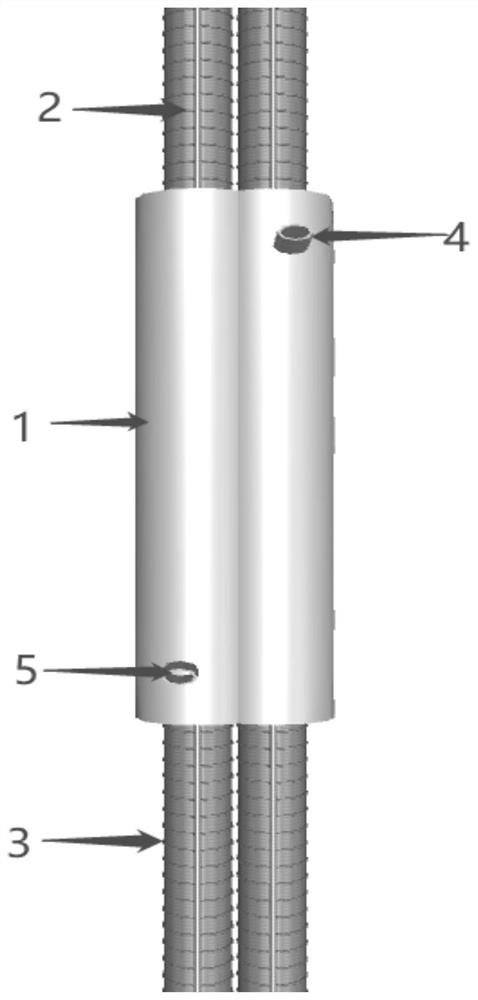

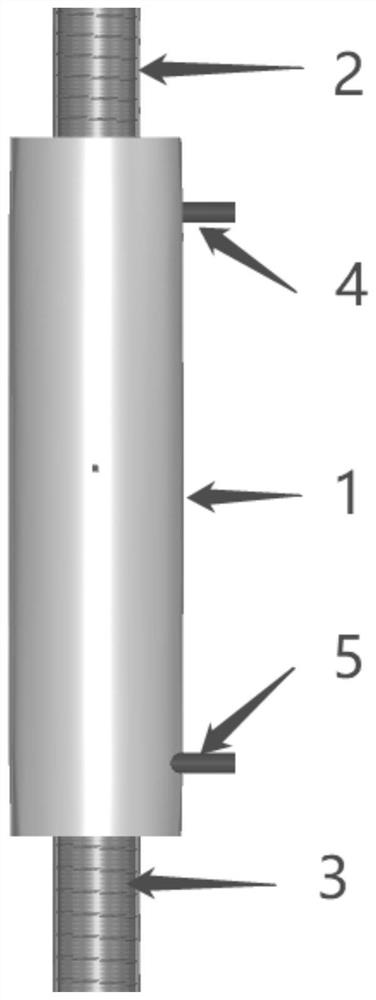

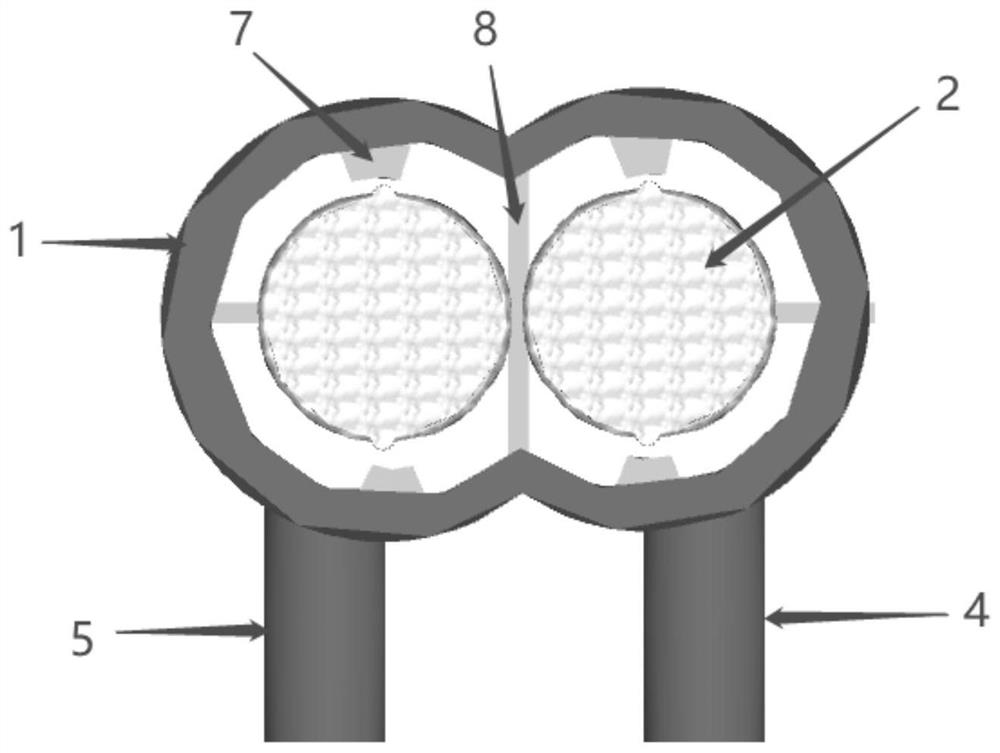

[0028] refer to Figure 1 to Figure 6 According to the present invention, the threaded grouting sleeve suitable for parallel connection of double ribs includes a sleeve body 1; an upper sealing plug 61 is provided at the top opening of the sleeve body 1, and a lower Sealing plug 62, grouting holes 5 are provided on the side of the bottom of the sleeve body 1, grout discharge holes 4 are provided on the side of the top of the sleeve body 1, limit barriers 8 are arranged in the sleeve body 1, and the lower parts of the two upper steel bars 2 After being inserted into the sleeve body 1 through the upper sealing plug 61, it contacts with the limit barrier 8, and the upper part of the two lower steel bars 3 passes through the lower sealing plug 62 and is inserted into the sleeve body 1, and then contacts with the limit barrier 8 In contact with each other, grouting materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com