Hopper structure for swing column limited angle construction and construction method thereof

A construction method and technology for swinging columns, which are applied in building construction, processing of building materials, construction, etc., can solve the problems of concrete pouring of swinging columns and the inability of ordinary hoppers to meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

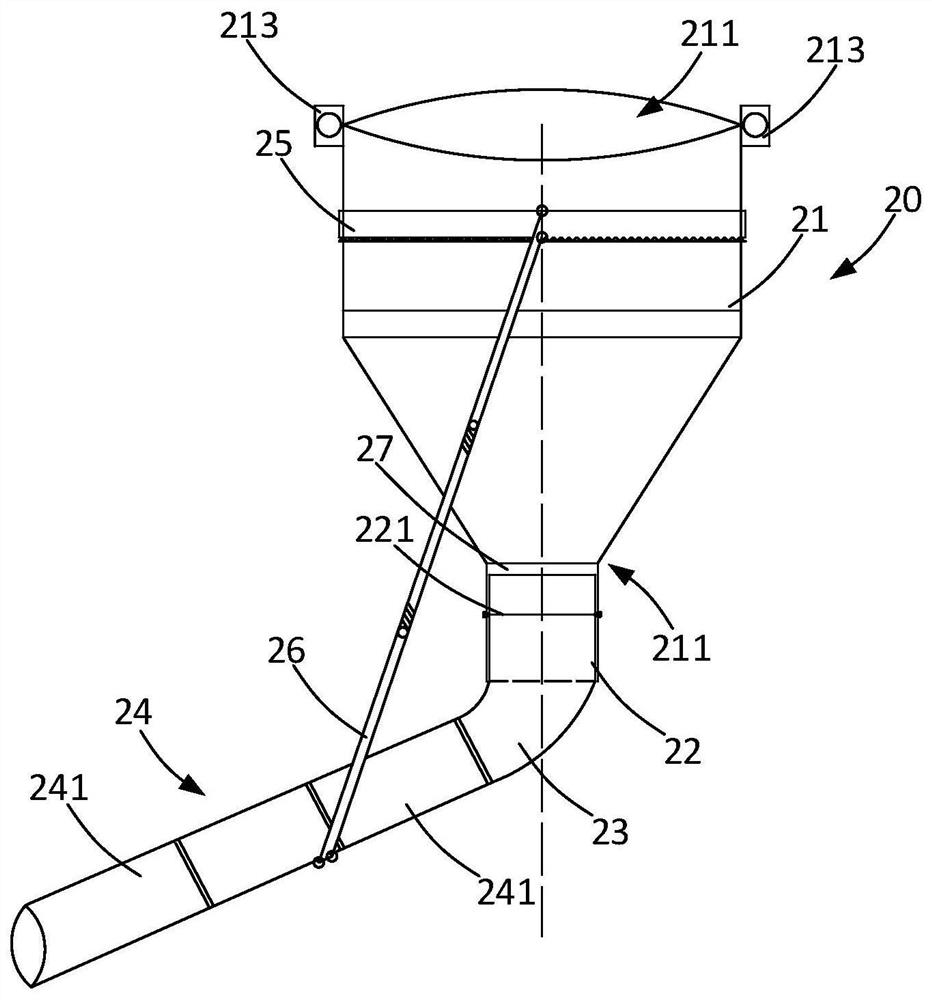

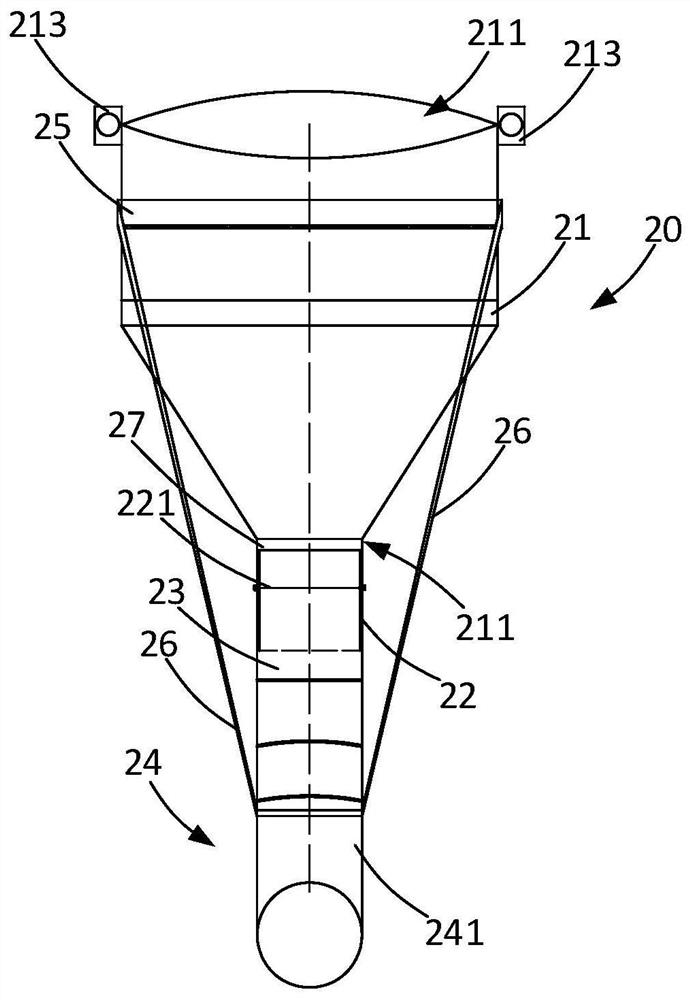

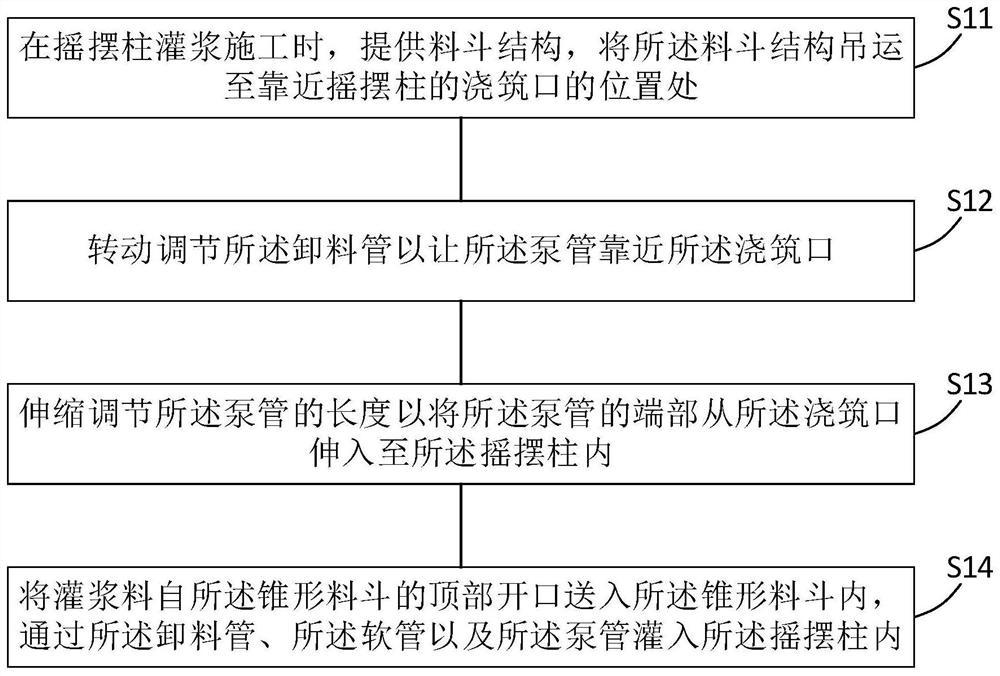

[0036] refer to figure 1 , The present invention provides a hopper structure and a construction method for construction of a swinging column with a limited angle, which is used to realize the material distribution construction of the pouring opening on the side of the swinging column, and can be applied to the material distribution construction of the pouring opening in a limited space. The top of the hopper structure of the present invention is an open conical hopper, a discharge pipe is rotatably connected to the bottom of the conical hopper, the discharge pipe can rotate 360° horizontally, and a hose is connected to the bottom of the discharge pipe. The hose has a certain stretching and deformation ability, which can provide free adjustment in the vertical direction. The bottom of the hose is connected with a pump tube whose length can be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com