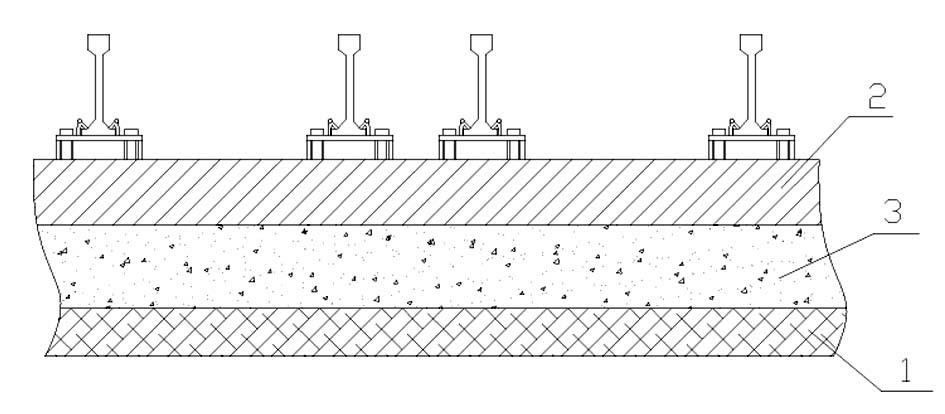

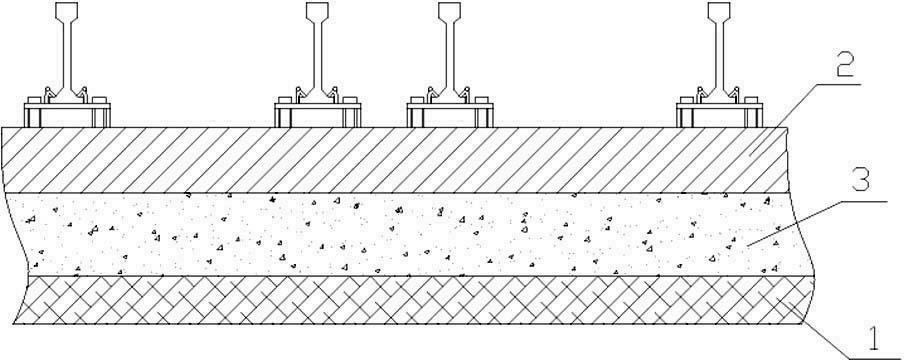

Concrete for railway switch base filling layer and pouring method

A technology of concrete and filling layers, applied in the direction of track, road, track maintenance, etc., can solve the problems that cannot guarantee the quality of concealed key engineering parts, cannot fully adapt to various construction environments, and is not conducive to the continuity of dense concrete pouring, etc. Achieve excellent self-filling performance, improve the construction environment and the surrounding environment of the site, and achieve the effects of excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Railway turnout base filling layer 1M according to the present invention 3 Concrete (self-leveling concrete) is made by mixing the following raw materials: specific surface area ≤ 350 m 2 / kg P 042.5 ordinary Portland cement 370kg; S95 type, specific surface area 350-500 m 2 90 kg of slag powder per kg; Class I, fly ash with a fineness of ≤12% 90 kg; ANF concrete expansion agent 44 kg; Sand in Zone II 866 kg; 5-10mm continuously graded crushed stone 738 kg; 184 kg of water; 7.7 kg of AN4000 polycarboxylate superplasticizer.

[0018] In order to ensure the pouring quality of the filling layer of the railway turnout base, the materials used should also pay attention to the following points:

[0019] (1) Portland cement or ordinary Portland cement should be used for cement, and early-strength cement should not be used, in which free calcium oxide ≤ 1.0%, alkali content ≤ 0.80%, C in clinker 3 A≤8%,CL - Content ≤0.06%, SO 3 Content≤3.5%.

[0020] (2) Mineral admixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com