Ball pouring device for bearing automatic assembly and using method thereof

An automatic assembly and bead filling technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of unfavorable follow-up use, large space occupation, troublesome maintenance, etc., and achieve automation, high working reliability, and replacement The effect of manual manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

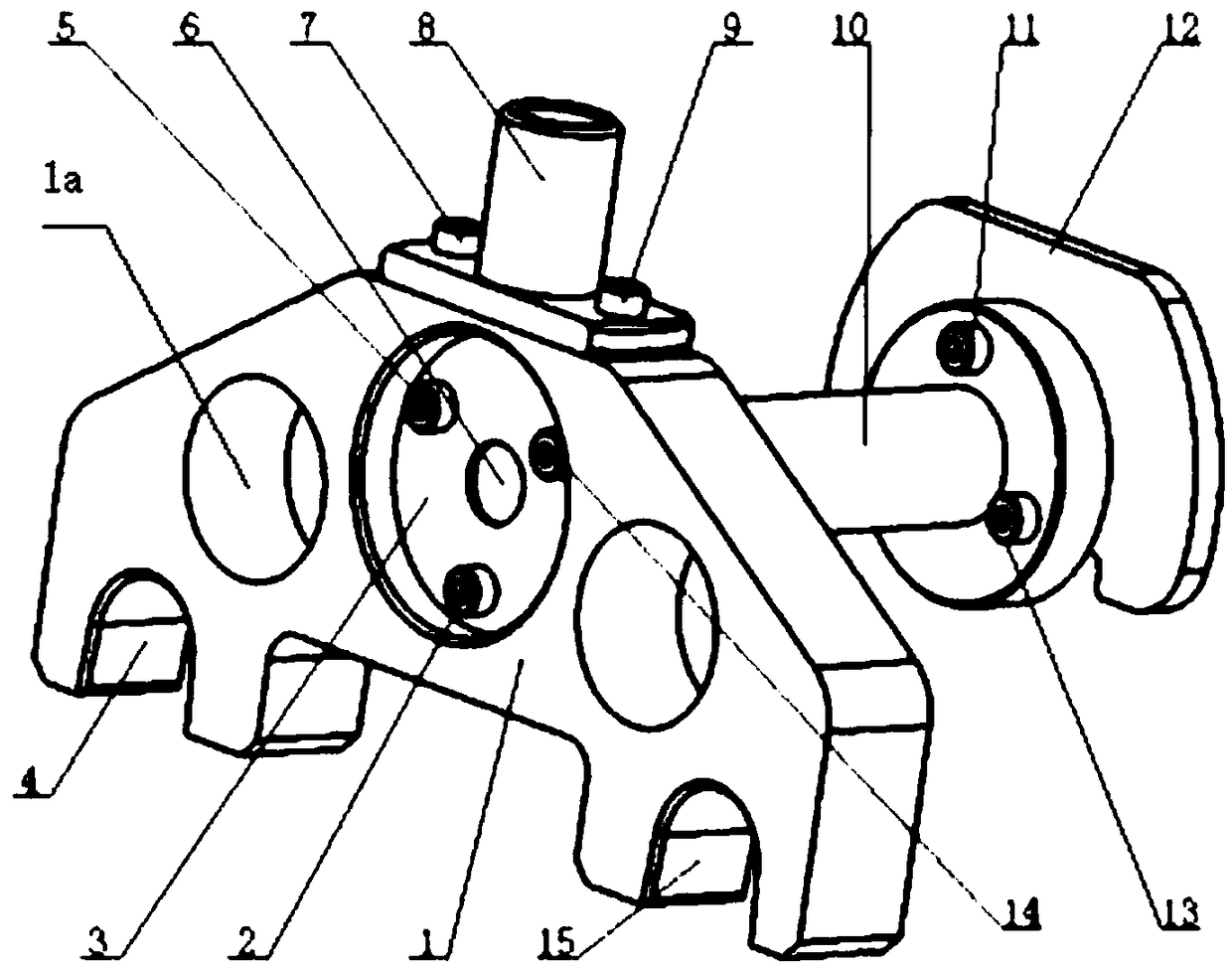

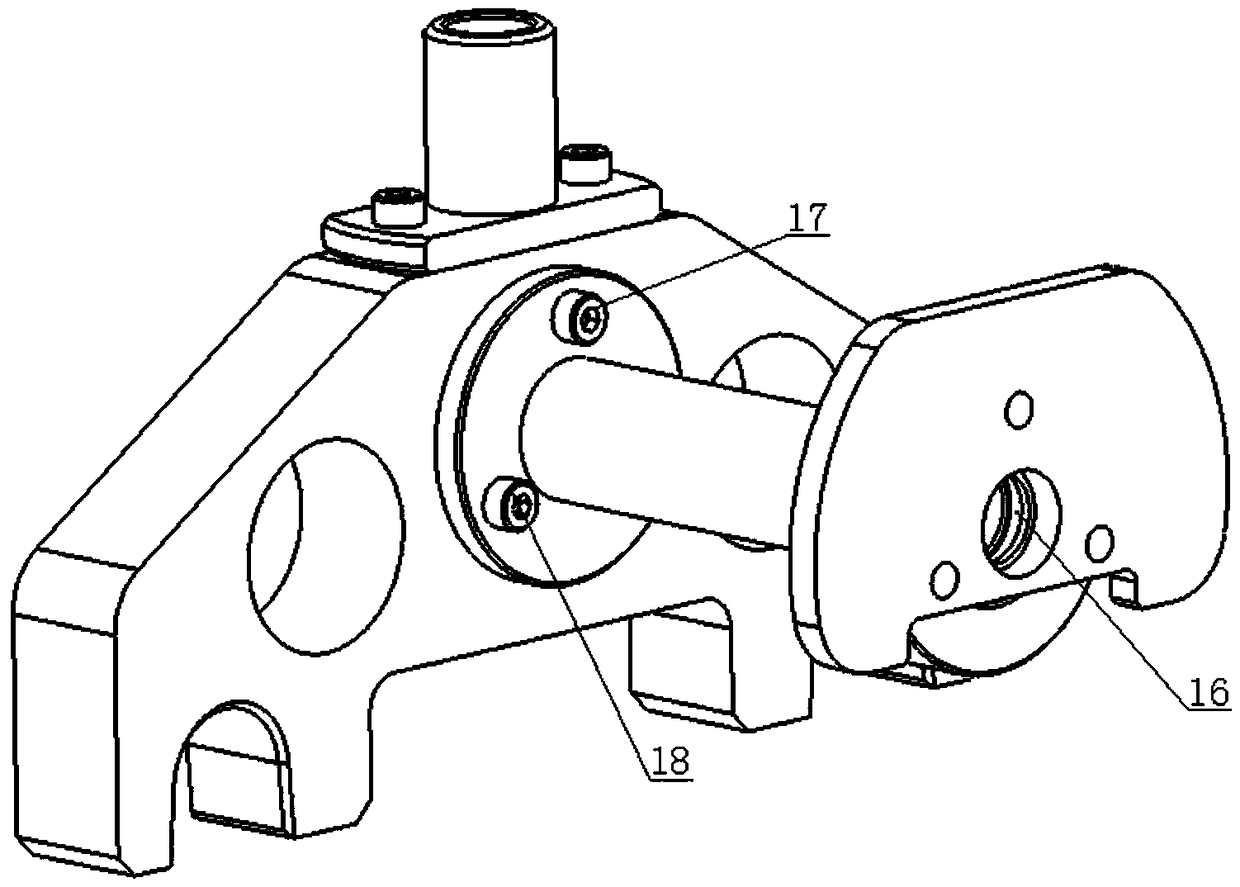

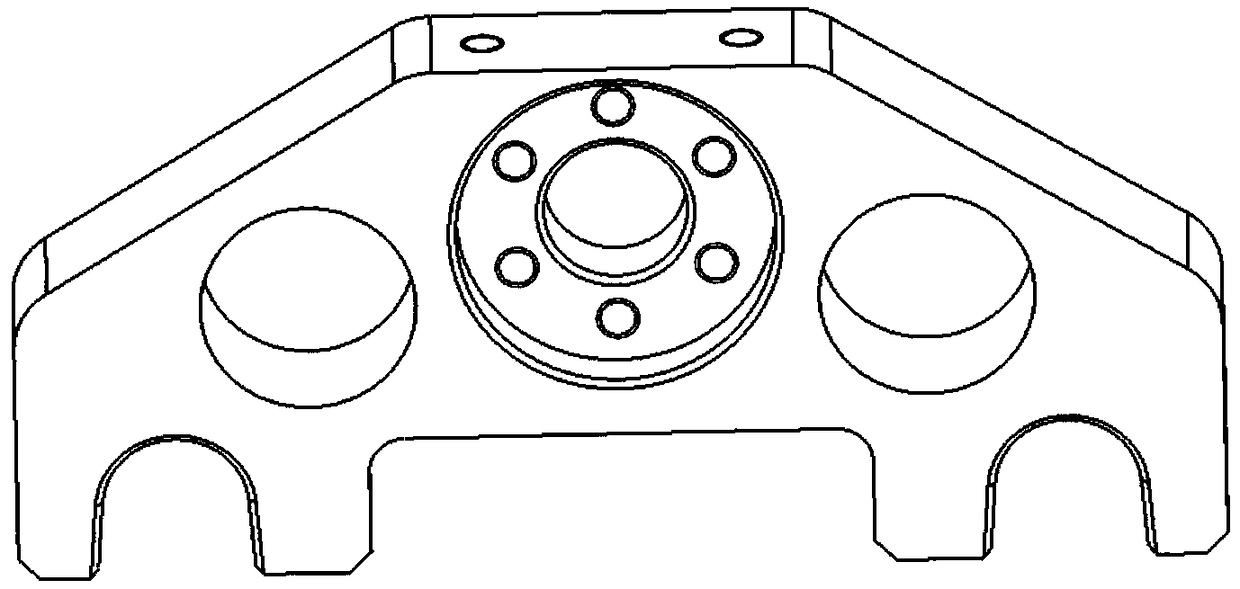

[0032] Such as Figure 1 to Figure 8 As shown, a bead filling device for automatic bearing assembly includes a bead filling holder 1. The upper end of the bead filling holder 1 is provided with a grasping handle 8 that is convenient for robots to grasp. The bead filling holder 1 A ball conveying pipe 10 for conveying balls is provided on one end surface of the ball, and a baffle mechanism that cooperates with the ball conveying pipe 10 is provided on the ball filler bracket 1.

[0033] The grasping handle 8 provided in the present invention is convenient for the robot to grasp.

[0034] The guide groove 1 4 and guide groove 2 15 on the ball filler bracket 1 are configured to facilitate the smooth movement and accurate positioning of the filler on the bearing assembly platform. The ball transfer tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com