Butterfly valve sealing performance testing system under high-temperature condition

A technology of sealing performance and testing system, which is applied in the direction of fluid tightness testing, machine/structural component testing, liquid tightness measurement using liquid/vacuum degree, etc., to achieve accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

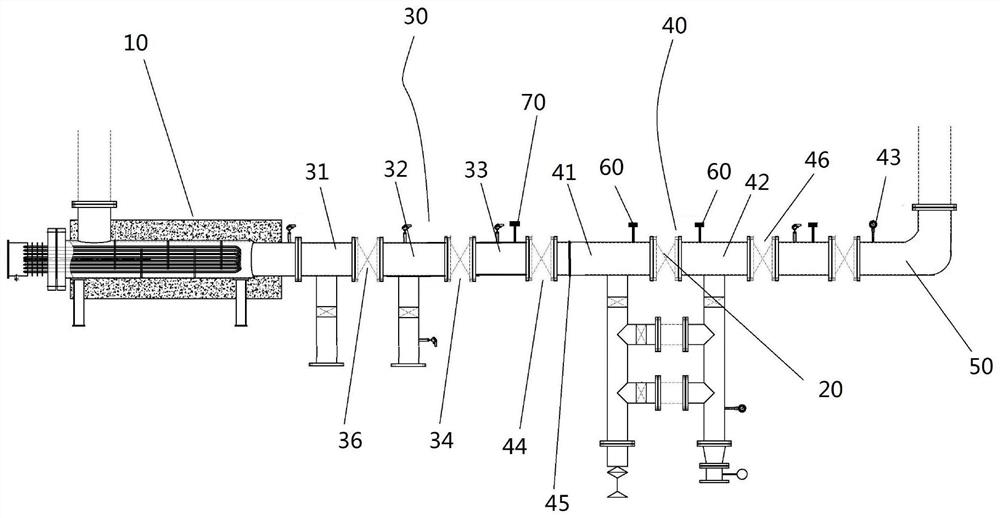

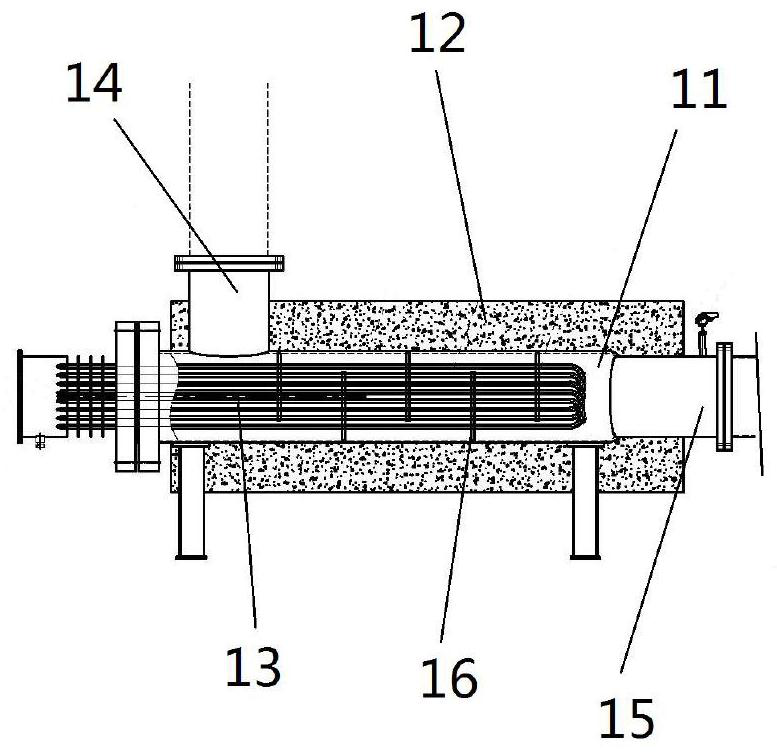

[0026] see figure 1 The shown testing system includes a heating unit 10 , a flow control unit 30 and a testing unit 40 . The heating unit 10 heats the test medium to a set temperature. The flow control unit 30 is connected between the heating unit 10 and the test unit 40, and is used to regulate the flow of the test medium; the test unit 40 includes a test tube one 41, a test tube two 42 and a flowmeter 43, and the butterfly valve 20 to be tested is installed in the test tube Between one 41 and test tube two 42, between test tube one 41 and flow control unit 30 is connected through butterfly valve one 44, a check valve 45 is installed in test tube one 41, test tube two 42 is connected with outlet pipe 50, test The second pipe 42 is connected to the air outlet pipe 50 through the second butterfly valve 46, and the flow meter 43 is arranged on the second test pipe 42. The heated test medium enters the test unit 40 after the flow rate and velocity are adjusted by the flow contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com